This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

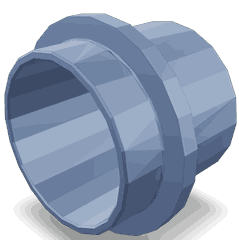

The Cummins 3871364 Spring Retainer is a component designed for use in commercial trucks. It serves a specific function within the engine’s valve train system, ensuring the proper operation of the valves. Understanding its purpose and role is fundamental for maintaining engine efficiency and reliability.

Basic Concepts of Spring Retainers

Spring retainers are mechanical components used to hold valve springs in place within an engine. They ensure that the springs remain correctly positioned and function as intended. In automotive applications, spring retainers are essential for maintaining the integrity of the valve train, which is responsible for the opening and closing of engine valves in synchronization with the pistons’ movement 1.

Purpose of the Cummins 3871364 Spring Retainer

This Cummins part plays a role in the valve train system by securing the valve springs. This ensures that the valves open and close at the correct times, which is vital for the engine’s combustion process. By maintaining the proper tension and position of the valve springs, the retainer contributes to the overall efficiency and performance of the engine 2.

Key Features

The Cummins 3871364 Spring Retainer is characterized by its robust material composition, typically made from high-strength steel to withstand the demanding conditions within a commercial truck engine. Its design includes precise engineering to ensure a secure fit and optimal performance. The manufacturing process may involve heat treatment to enhance durability and resistance to wear.

Benefits

The use of the Cummins 3871364 Spring Retainer offers several advantages. It contributes to improved engine performance by ensuring consistent valve operation. The durable construction of the retainer enhances the engine’s reliability, making it suitable for heavy-duty applications. Additionally, its design helps in reducing the risk of valve train failures, leading to longer engine life and reduced maintenance costs 3.

Installation and Compatibility

Proper installation of the Cummins 3871364 Spring Retainer is crucial for its effective function. It should be installed according to the manufacturer’s guidelines, using the appropriate tools and following safety precautions. Compatibility with specific engine models and configurations should be verified to ensure optimal performance and integration within the engine system.

Troubleshooting and Maintenance

Common issues with spring retainers may include wear, deformation, or failure due to extreme conditions. Regular inspection and maintenance can help identify potential problems early. Diagnostic procedures should be followed to assess the condition of the retainer and determine if replacement is necessary. Maintenance tips include checking for proper installation, ensuring compatibility with engine components, and following recommended service intervals.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of diesel engines and related technologies. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance engine components. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of commercial transportation.

Cummins Spring Retainer Part 3871364 in Engine Applications

The Cummins Spring Retainer part number 3871364 is a critical component in various Cummins engine models. This part is designed to ensure the secure retention of springs within the engine, maintaining the integrity and performance of the engine’s internal mechanisms.

ISX CM570 Engines

In the ISX CM570 engines, the Spring Retainer part 3871364 plays a vital role in the engine’s operation. It is used to hold specific springs in place, which are integral to the engine’s valve train and other moving parts. The retention of these springs is crucial for the smooth and reliable functioning of the engine, ensuring that the engine’s components operate within their designed parameters.

Grouping of Engines

The Spring Retainer part 3871364 is also applicable to a range of other Cummins engines, where it serves the same fundamental purpose of securing springs. This part is engineered to fit seamlessly into the design of these engines, providing a reliable and durable solution for maintaining the engine’s operational integrity.

By ensuring that the springs are properly retained, the part 3871364 contributes to the overall efficiency and longevity of the engine, making it a key component in the maintenance and repair of these engines.

Understanding the Integration of Part 3871364 Spring Retainer in Engine Systems

The Spring Retainer, identified by part number 3871364, is an essential component in the orchestration of various engine systems. Its primary function is to secure and maintain the position of springs within these systems, ensuring optimal performance and longevity of the engine’s moving parts.

Interaction with Engine Brake Lever

In the context of the Engine Brake Lever, the Spring Retainer plays a supportive role. It ensures that the spring associated with the lever mechanism is held in place, allowing for consistent and reliable operation of the brake system. This is particularly important during engine braking, where precise control and immediate response are required.

Role in Engine Brake Tune-Up Kit

When incorporated into an Engine Brake Tune-Up Kit, the Spring Retainer contributes to the kit’s effectiveness by securing springs that are part of the tuning process. This ensures that adjustments made during a tune-up are maintained, leading to improved engine performance and efficiency.

Coordination with Lever and Rocker Mechanisms

The Spring Retainer is also integral to the functionality of Lever and Rocker mechanisms within the engine. By securing the springs in these components, it ensures smooth and consistent operation. This is vital for the precise control of valve timing and operation, directly impacting the engine’s overall performance.

Integration in Rocker Lever Top Level Assembly

In the Rocker Lever Top Level Assembly, the Spring Retainer’s role is to maintain the integrity of the spring system within the assembly. This is essential for the accurate transfer of motion from the camshaft to the valves, ensuring that the engine operates efficiently and effectively.

Contribution to Assembly

Finally, in a broader Assembly context, the Spring Retainer’s role is to ensure that all spring-loaded components within the assembly are securely held in place. This is fundamental for the assembly’s structural integrity and operational reliability, contributing to the engine’s smooth and efficient operation.

Conclusion

The Cummins 3871364 Spring Retainer is a vital component in the maintenance and operation of commercial truck engines. Its role in securing valve springs ensures the efficient and reliable operation of the engine’s valve train system. Understanding and properly maintaining this part is crucial for maximizing engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.