This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3914424 Tension Spring is a specialized component designed for use in commercial trucks. Its primary purpose is to maintain tension within specific mechanical systems, ensuring smooth and efficient operation. This spring is integral to the functionality of various truck systems, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Tension Springs

Tension springs are mechanical devices that store energy when stretched. They function by exerting a force to return to their original, uncompressed state. These springs are widely used in mechanical systems to provide consistent tension, support, and stability. Their applications range from simple mechanisms to complex machinery, where maintaining precise tension is crucial for operation 1.

Role of the 3914424 Tension Spring in Truck Operation

The 3914424 Tension Spring plays a specific role in the operation of commercial trucks by maintaining the necessary tension in various systems. It interacts with components such as the engine’s valve train, where it helps keep valves properly seated and ensures efficient engine performance. Additionally, it may be used in other systems where consistent tension is required to prevent wear and ensure smooth operation 2.

Key Features

The 3914424 Tension Spring is characterized by several key features that enhance its performance. It is typically made from high-quality materials, such as spring steel, which provides durability and resistance to fatigue. The design specifications of this spring, including its length, diameter, and coil count, are tailored to meet the specific requirements of commercial truck applications. Unique attributes, such as corrosion resistance and precise tension control, further contribute to its reliability and longevity.

Benefits of Using the 3914424 Tension Spring

Utilizing the 3914424 Tension Spring offers several advantages in truck operations. Its high-quality construction ensures improved reliability and durability, reducing the likelihood of failure and the need for frequent replacements. Additionally, the spring’s precise tension control enhances the efficiency of the systems it supports, contributing to overall truck performance and longevity.

Installation Considerations

Proper installation of the 3914424 Tension Spring is vital to ensure it functions correctly within the truck’s mechanical system. Guidelines for installation include verifying the spring’s dimensions match the application requirements, ensuring it is properly seated in its housing, and checking for any signs of damage or deformation. Following these best practices helps maintain the spring’s performance and longevity.

Troubleshooting Common Issues

Common problems associated with tension springs in commercial trucks include loss of tension, spring fatigue, and corrosion. Troubleshooting steps to address these issues involve inspecting the spring for signs of wear or damage, ensuring it is correctly installed, and replacing it if necessary. Regular maintenance and timely replacements can prevent many of these issues from arising.

Maintenance Tips

Regular maintenance of the 3914424 Tension Spring is essential to ensure its longevity and optimal performance. Maintenance tips include periodic inspection for signs of wear, corrosion, or fatigue, cleaning the spring and its housing to prevent buildup, and replacing the spring according to the manufacturer’s recommendations or when signs of degradation are observed. Adhering to these maintenance practices helps maintain the spring’s functionality and extends its service life.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s extensive product range and dedication to advancing technology make it a trusted name in the automotive and heavy-duty truck industries.

Cummins Engine Part 3914424: Tension Spring

The Cummins part number 3914424, identified as a Tension Spring, is a critical component in the engine’s operational mechanics. This part is integral to ensuring that various engine parts maintain the correct tension, which is essential for the smooth functioning of the engine.

Application in Cummins Engines

The Tension Spring, part number 3914424, is designed to fit seamlessly within the Cummins engine family. It is particularly relevant in the following engines:

- 6B5.9: This engine model benefits from the precise tension control provided by the 3914424 Tension Spring. It ensures that the components it interacts with are held securely, reducing wear and tear and enhancing overall engine longevity.

Importance in Engine Performance

The role of the Tension Spring in the engine cannot be overstated. It maintains the necessary tension on various parts, ensuring that they operate within their designed parameters. This is crucial for the following reasons:

- Prevents Component Failure: By maintaining the correct tension, the spring helps prevent parts from becoming loose or misaligned, which could lead to catastrophic failures.

- Enhances Efficiency: Proper tension ensures that moving parts operate smoothly, reducing friction and improving the engine’s efficiency.

- Increases Longevity: By reducing the stress on engine components, the tension spring contributes to the overall durability and lifespan of the engine.

Installation and Maintenance

When installing or replacing the Tension Spring, it is essential to follow the manufacturer’s guidelines to ensure it is correctly positioned and tensioned. Regular maintenance checks should be performed to verify that the spring is in good condition and functioning as intended.

Compatibility

The 3914424 Tension Spring is specifically engineered to fit within the Cummins engine architecture, ensuring compatibility and reliability. It is essential to use the correct part number when sourcing replacements to maintain the engine’s performance and integrity.

Role of Part 3914424 Tension Spring in Engine Systems

In the context of engine systems, the 3914424 Tension Spring is integral to the functionality of several components, ensuring smooth operation and precise control.

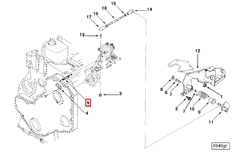

Integration with Brackets

When incorporated into brackets, the 3914424 Tension Spring provides necessary tension to maintain alignment and stability. This is particularly important in scenarios where brackets support moving parts or need to withstand vibrational forces. The spring’s ability to absorb and distribute stress helps in prolonging the lifespan of the bracket and the components it supports.

Application in Throttle Control Systems

In throttle control systems, the 3914424 Tension Spring plays a significant role in maintaining the desired tension on the throttle linkage. This ensures that the throttle responds accurately to driver inputs, providing consistent acceleration and deceleration. The spring’s tension helps in returning the throttle to its default position when not actuated, which is essential for maintaining engine idle speed and preventing unintended acceleration.

By understanding the specific applications and benefits of the 3914424 Tension Spring in these components, engineers and mechanics can better appreciate its importance in ensuring the reliable performance of engine systems.

Conclusion

The Cummins 3914424 Tension Spring is a vital component in the operation of commercial trucks and Cummins engines. Its role in maintaining tension within mechanical systems ensures smooth and efficient operation, contributing to the overall performance and reliability of the vehicle. Proper installation, regular maintenance, and understanding its applications are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.