This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

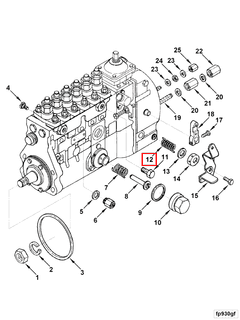

The Cummins 3920912 Return Spring is a critical component for commercial trucks, designed to enhance the efficiency and reliability of vehicle systems. Understanding its function and significance is essential for maintaining optimal truck performance.

Basic Concepts of Return Springs

Return springs are mechanical components that restore systems or parts to their original positions after actuation. They operate based on the principle of elastic deformation, storing energy when compressed or stretched and releasing it to return components to their resting state 1. In automotive applications, these springs are vital in braking systems, clutches, and engine components, ensuring proper part alignment after use.

Purpose of the Cummins 3920912 Return Spring

This Cummins part ensures that specific truck components return to their default positions after being actuated. It is crucial for the smooth and reliable operation of certain systems within the truck. A malfunctioning return spring can lead to improper component alignment, reduced system efficiency, or safety concerns, underscoring the importance of its correct function 2.

Key Features

The Cummins 3920912 Return Spring is known for its robust design and high-quality material composition, which contribute to its durability and performance. Crafted from materials resistant to wear and corrosion, this part ensures longevity under demanding conditions. Its design is tailored to meet the specific requirements of its application, providing reliable performance in commercial truck environments 3.

Benefits of Using the Cummins 3920912 Return Spring

Using this part offers several advantages, including improved reliability and performance within the truck’s systems. Its design and material composition contribute to enhanced system efficiency. Additionally, the spring’s ease of maintenance and compatibility with specific truck models make it a practical choice for fleet managers and technicians aiming to ensure the smooth operation of their vehicles.

Installation and Integration

Proper installation of this part is vital for its effective function within a truck’s system. Installation guidelines recommend ensuring the truck’s system is clean and free of debris before proceeding. The use of appropriate tools is advised to avoid damage to the spring or surrounding components. Following manufacturer instructions ensures correct integration, contributing to the spring’s performance and durability.

Troubleshooting and Maintenance

Common issues with return springs include wear, corrosion, and failure to return components to their original positions. Diagnosing problems may involve visual inspection for signs of damage or malfunction and testing the spring’s function within the system. Regular maintenance practices, such as cleaning and inspecting the spring for wear, can help prolong its lifespan and ensure optimal functioning.

Compatibility and Application

This part is designed for use in specific types of trucks and systems, with applications varying based on the model and engine type. Its compatibility ensures it meets the demands of its intended use, contributing to the efficiency and reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong presence in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and reputation for reliability underscore the quality and performance of components like the 3920912 Return Spring.

Conclusion

The Cummins 3920912 Return Spring plays a significant role in the operation and maintenance of commercial trucks. Its design, material composition, and compatibility with specific truck models contribute to the reliability and efficiency of vehicle systems. Proper installation, regular maintenance, and understanding its function are key to ensuring the optimal performance of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.