This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

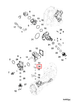

The Cummins 3930510 Torsion Spring is a specialized component designed for use in commercial trucks. Its primary purpose is to provide the necessary tension and stability in various mechanical systems within these vehicles. Understanding the role of torsion springs can enhance the maintenance and operation of commercial trucks.

Basic Concepts of Torsion Springs

Torsion springs are mechanical devices that store and release rotational energy. They operate by twisting along their axis when a force is applied and return to their original shape once the force is removed. This principle of torsion is fundamental to the mechanics of these springs, allowing them to be used in a wide range of applications, from simple toys to complex machinery. In mechanical systems, torsion springs are often employed to maintain tension, provide resistance, or store energy for later use 1.

Role of the 3930510 Torsion Spring in Truck Operation

The 3930510 Torsion Spring plays a specific role in the operation of commercial trucks by providing the necessary tension in systems that require rotational force. It interacts with various components, ensuring that they function correctly and efficiently. This spring contributes to the overall functionality of the truck by maintaining the integrity and performance of the systems it is part of 2.

Key Features of the 3930510 Torsion Spring

The 3930510 Torsion Spring is characterized by several key features that enhance its performance and durability. These include its material composition, which is typically a high-strength alloy designed to withstand significant stress and strain. The design specifications of the spring are tailored to meet the demanding requirements of commercial truck applications, ensuring reliable operation under various conditions. Additionally, the spring may possess unique attributes that further improve its functionality, such as a specific coil diameter or wire gauge that optimizes its torsional properties 3.

Benefits of Using the 3930510 Torsion Spring

Incorporating the 3930510 Torsion Spring into truck designs offers several benefits. These include improved reliability, as the spring is engineered to perform consistently under demanding conditions. Enhanced performance is another advantage, with the spring providing the necessary tension and stability to ensure optimal operation of the truck’s mechanical systems. Additionally, the longevity of the 3930510 Torsion Spring is notable, as its high-quality materials and precise design contribute to a longer service life compared to other types of springs.

Installation and Integration

Proper installation and integration of the 3930510 Torsion Spring are vital to ensure it functions correctly within the truck’s systems. Guidelines and best practices for installation include careful handling of the spring to avoid damage, precise alignment with the components it interacts with, and secure mounting to prevent movement during operation. Step-by-step instructions and tips can help ensure a proper fit and function, contributing to the overall performance and reliability of the truck.

Maintenance and Troubleshooting

Regular maintenance of the 3930510 Torsion Spring is important to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning to remove any debris that may affect its function, and lubrication if necessary to reduce friction and wear. Common issues that may arise with torsion springs include loss of tension, misalignment, or physical damage. Troubleshooting tips and preventive maintenance practices can help address these issues and prolong the life of the spring.

Cummins Corporation Overview

Cummins Corporation is a well-established entity in the commercial truck industry, known for its extensive history, diverse product range, and strong reputation for quality. The company offers a wide array of automotive components, including the 3930510 Torsion Spring, which is part of its commitment to providing reliable and high-performance parts. Cummins’ expertise and dedication to innovation make it a trusted source for commercial truck components, ensuring that their products meet the rigorous demands of the industry.

Cummins Engine Compatibility with Torsion Spring Part 3930510

The Torsion Spring part number 3930510, manufactured by Cummins, is a critical component in several engine models. This part is designed to provide essential functionality in the engine’s operation, ensuring smooth and reliable performance. Here is a detailed look at how this part fits within the specified engine models:

B5.9 G and B5.9 GAS PLUS CM556

The B5.9 G and B5.9 GAS PLUS CM556 engines both utilize the Torsion Spring part 3930510. This part plays a pivotal role in the engine’s internal mechanisms, contributing to the overall efficiency and durability of the engine. The torsion spring is typically involved in the engine’s valve train system, where it helps maintain the proper tension and alignment of the valves. This ensures that the engine operates smoothly and prevents potential wear and tear that could lead to costly repairs.

G5.9

The G5.9 engine also incorporates the Torsion Spring part 3930510. Similar to its application in the B5.9 G and B5.9 GAS PLUS CM556 engines, this part is integral to the engine’s valve train system. The torsion spring’s role in the G5.9 engine is to maintain the correct tension on the valve springs, which is crucial for the engine’s performance and longevity. By ensuring that the valves open and close at the precise moments, the torsion spring helps to optimize the engine’s combustion process, leading to better fuel efficiency and reduced emissions.

Grouping of Engines

The B5.9 G and B5.9 GAS PLUS CM556 engines can be grouped together due to their similar design and the shared use of the Torsion Spring part 3930510. Both engines benefit from the torsion spring’s ability to maintain proper valve tension, which is essential for their operation. The G5.9 engine, while distinct in some aspects, also relies on this part for its valve train system, highlighting the importance of the torsion spring across different engine models.

Role of Part 3930510 Torsion Spring in Engine Systems

The part 3930510 torsion spring is integral to the efficient operation of several components within engine systems. It provides the necessary tension and return force for various mechanical parts, ensuring smooth and precise functionality.

Air Fuel Throttle Valve

In the air fuel throttle valve, the torsion spring plays a significant role in maintaining the correct position of the valve plate. As the valve opens and closes in response to engine demand, the spring ensures that the valve returns to its default position when not actuated. This consistent return action is essential for maintaining the proper air-fuel mixture, which is vital for optimal engine performance and fuel efficiency.

Assembly Kit

Within an assembly kit, the torsion spring is often used to provide tension in components such as the control linkage lever. This ensures that the lever operates within its designed parameters, offering reliable and repeatable movement. The spring’s ability to store and release energy helps in achieving the precise mechanical advantage required for the lever to function correctly.

Control Linkage Lever

The control linkage lever relies on the torsion spring to maintain tension throughout its range of motion. This tension is crucial for the lever to transmit force effectively from the actuator to the controlled component. Whether it’s part of a fuel control system or another mechanical linkage, the spring ensures that the lever operates smoothly and returns to its neutral position, preventing any unintended movements that could affect engine performance.

Module

In modules that incorporate mechanical components, the torsion spring is used to ensure that moving parts within the module operate under consistent tension. This is particularly important in fuel control modules, where the spring helps in maintaining the integrity of the fuel delivery system by ensuring that components like valves and levers function within their specified ranges.

Fuel Control

The fuel control system benefits significantly from the torsion spring’s properties. By providing the necessary tension in components such as the fuel control lever and valve, the spring ensures that fuel is delivered accurately and consistently. This precision is essential for maintaining engine efficiency and reducing emissions. The spring’s role in returning components to their default positions also helps in preventing fuel leaks and ensuring that the system operates within safe parameters.

Conclusion

The Cummins 3930510 Torsion Spring is a critical component in the operation of commercial trucks and various engine models. Its role in maintaining tension and stability in mechanical systems ensures the smooth and efficient operation of these vehicles. Understanding the features, benefits, and proper maintenance of this part can significantly enhance the performance and longevity of commercial trucks and engines.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.