This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

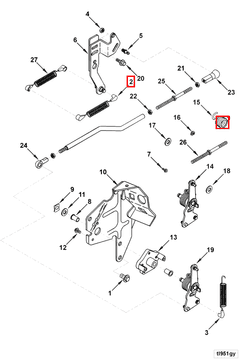

The Cummins 3931510 Tension Spring is a vital component designed for use in commercial trucks. Its purpose is to provide the necessary tension in various mechanical systems within the truck, ensuring smooth operation and efficiency. This spring is integral to maintaining the proper function of certain truck components, contributing to the overall performance and reliability of the vehicle 2.

Basic Concepts of Tension Springs

Tension springs are mechanical devices that store energy when stretched. They are designed to exert a force to return to their original length when the stretching force is removed. These springs are commonly used in various applications where a pulling force is required. In mechanical systems, tension springs play a role in maintaining tension within components, ensuring they operate correctly under different conditions 4.

Role of the 3931510 Tension Spring in Truck Operation

The Cummins 3931510 Tension Spring plays a specific role in the operation of a truck by providing the necessary tension in systems or components where a pulling force is required. This spring interacts with various parts of the truck, ensuring they function correctly. Its application can be found in systems where maintaining a consistent tension is crucial for the operation, such as in the suspension system, engine components, or other mechanical assemblies 3.

Key Features

The Cummins 3931510 Tension Spring is characterized by several key features that enhance its performance. These include its material composition, which is typically made from high-quality steel to ensure durability and resistance to wear. The design specifications of this spring are tailored to meet the demands of commercial truck applications, providing the necessary tension and reliability. Additionally, any unique attributes, such as a specific coil configuration or surface treatment, contribute to its performance and longevity 1.

Benefits

The Cummins 3931510 Tension Spring offers several benefits in truck applications. Its design and material composition contribute to improved reliability and efficiency in the systems it serves. By maintaining the proper tension, this spring helps ensure the smooth operation of truck components, reducing the likelihood of mechanical failures. Furthermore, its durability and resistance to wear contribute to the overall longevity of the truck’s mechanical systems 2.

Troubleshooting and Maintenance

Common issues that may arise with tension springs include loss of tension, deformation, or failure due to wear and tear. Troubleshooting these problems involves inspecting the spring for signs of damage or wear, testing its tension, and comparing it to the manufacturer’s specifications. Maintenance practices to ensure the longevity and performance of the Cummins 3931510 Tension Spring include regular inspection, cleaning, and replacement when necessary. Adhering to these practices helps maintain the spring’s performance and contributes to the overall reliability of the truck 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and performance in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to innovation and customer satisfaction has solidified its position as a trusted partner in the trucking industry 3.

Cummins Engine Part 3931510: Tension Spring

The Cummins part 3931510, a Tension Spring, is a critical component in the engine systems of various Cummins engines. This part is designed to maintain tension within the engine’s mechanisms, ensuring smooth operation and longevity of the engine components.

Application in Cummins Engines

-

6B5.9 Engine Series

- The 6B5.9 engine series utilizes the Tension Spring part 3931510 to maintain the proper tension in the valve train system. This ensures that the valves operate with the correct force, preventing issues such as valve float and ensuring efficient combustion.

-

Other Cummins Engines

- Beyond the 6B5.9 series, the part 3931510 is also integral to other Cummins engine models. It is employed in various systems where maintaining tension is crucial, such as in the fuel injection system, turbocharger mechanisms, and other moving parts that require consistent force to function correctly.

Importance of the Tension Spring

-

Prevents Mechanical Failure

- By maintaining the correct tension, the part 3931510 helps prevent mechanical failure and wear on engine components. This is particularly important in high-stress environments where engines are subjected to continuous operation.

-

Enhances Performance

- Proper tension ensures that all parts of the engine work in harmony, leading to enhanced performance and efficiency. This is vital for maintaining the engine’s power output and reliability over time.

-

Facilitates Smooth Operation

- The Tension Spring part 3931510 contributes to the smooth operation of the engine by ensuring that all moving parts are properly aligned and under the correct tension, reducing the risk of mechanical issues and downtime.

Role of Part 3931510 Tension Spring in Engine Systems

The part 3931510 tension spring is an integral component in the operation of various engine systems, particularly in the coordination and regulation of mechanical movements.

In the context of a lever system, the tension spring ensures that the lever returns to its default position after being actuated. This is essential for maintaining the precision and reliability of the lever’s function, whether it is used for controlling fuel flow, adjusting valve timing, or managing other critical engine operations. The spring’s consistent tension helps in reducing wear and tear on the lever mechanism by providing a smooth and controlled return motion.

When integrated into a throttle system, the tension spring plays a significant role in maintaining the throttle plate’s position. It ensures that the throttle returns to its idle position when the accelerator pedal is released, which is vital for engine stability and fuel efficiency. The spring’s tension must be calibrated correctly to balance the force applied by the driver with the need for the throttle to return smoothly, preventing any unintended acceleration or deceleration.

In a throttle kit, which often includes multiple components designed to work in unison for optimal engine performance, the tension spring contributes to the harmonious operation of the entire system. It assists in the precise modulation of air intake by ensuring that the throttle body components move with the correct amount of resistance. This is particularly important in high-performance engines where even minor inconsistencies can lead to significant changes in engine behavior.

Overall, the part 3931510 tension spring is a key element in ensuring that engine components operate with the required precision and reliability, contributing to the overall efficiency and performance of the engine system 4.

Conclusion

The Cummins 3931510 Tension Spring is a critical component in the operation of commercial trucks and Cummins engines. Its role in maintaining the necessary tension within various mechanical systems ensures smooth operation, efficiency, and reliability. By understanding its key features, benefits, and applications, as well as adhering to proper maintenance practices, one can ensure the longevity and performance of this essential part.

-

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ ↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.