This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3933130 Tension Spring is a component designed for use in commercial truck operations. It serves a specific function within the truck’s mechanical system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Tension Springs

Tension springs are mechanical devices that store energy when stretched. They are designed to exert a force to return to their original length when the stretching force is removed. These springs are widely used in various mechanical systems for applications such as maintaining tension in belts, cables, and other components. Their ability to consistently return to a predefined length makes them invaluable in systems requiring precise tension control 1.

Role of the 3933130 Tension Spring in Truck Operation

The Cummins 3933130 Tension Spring plays a role in the truck’s mechanical system by maintaining the necessary tension on specific components. Its placement within the system allows it to ensure that parts operate within their designed parameters, contributing to the smooth and efficient operation of the truck. By providing consistent tension, it helps in the reliable functioning of associated mechanical parts, which is vital for the truck’s performance 2.

Key Features

This Cummins part is characterized by its material composition and design specifications, which are tailored to meet the demanding requirements of commercial truck operations. It is constructed from high-quality materials that offer durability and resistance to wear and tear. Its design includes specific dimensions and coil configurations that enhance its performance and longevity in the truck’s mechanical system.

Benefits

The use of the 3933130 Tension Spring in truck operations offers several benefits. It contributes to improved mechanical efficiency by ensuring that components operate with the correct tension. This results in enhanced durability and reliability of the truck’s mechanical system. The spring’s design and material composition also play a role in reducing maintenance needs and extending the operational life of the truck 3.

Troubleshooting and Maintenance

Common issues with tension springs may include loss of tension, physical damage, or fatigue over time. Troubleshooting these problems involves inspecting the spring for signs of wear, ensuring it is correctly installed, and replacing it if necessary. Regular maintenance practices, such as checking for proper tension and inspecting for damage, can help ensure the longevity and optimal performance of the 3933130 Tension Spring.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Engine Part 3933130: Tension Spring Application

The Cummins part number 3933130, a Tension Spring, is a critical component in various engine systems. This part is designed to maintain tension in specific engine mechanisms, ensuring optimal performance and longevity of the engine.

Application in Engine 6B5.9

In the Cummins 6B5.9 engine, the Tension Spring part number 3933130 plays a vital role in maintaining the integrity of the engine’s internal components. It is typically used in conjunction with valve systems, fuel injection mechanisms, or other moving parts that require consistent tension to function correctly.

The 6B5.9 engine, known for its robust design and reliability, benefits from the precision and durability of the 3933130 Tension Spring. This part ensures that the engine’s components operate smoothly, reducing wear and tear and preventing potential failures.

Grouping with Similar Engines

The 3933130 Tension Spring is also applicable to a range of other Cummins engines, where similar design and operational requirements exist. These engines often share common components and systems, making the tension spring a versatile and essential part across multiple engine models.

For instance, in engines within the same series or those that have similar valve train designs, the 3933130 Tension Spring can be used interchangeably. This commonality allows for easier maintenance and part replacement, providing a cost-effective solution for engine repair and upkeep.

Importance of the Tension Spring

The role of the Tension Spring in engine operation cannot be overstated. It ensures that moving parts remain under the correct tension, which is crucial for the efficient and safe operation of the engine. Without proper tension, components can become loose, leading to increased friction, noise, and potential mechanical failure.

Role of Part 3933130 Tension Spring in Engine Systems

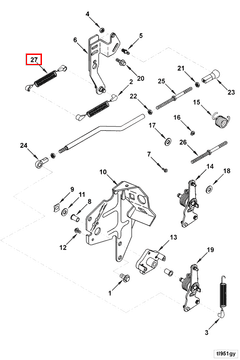

The part 3933130 Tension Spring is an integral component in various engine systems, ensuring smooth operation and precise control.

Engine Switch Kit

In the engine switch kit, the tension spring maintains consistent pressure on the switch mechanism. This ensures reliable engagement and disengagement of the engine, contributing to the overall stability and responsiveness of the system.

Exhaust Brake Kit

Within the exhaust brake kit, the tension spring plays a key role in modulating the brake’s activation. It helps in maintaining the correct tension on the brake components, allowing for efficient and controlled deceleration without undue stress on the system.

Lever Mechanisms

For lever-based systems, such as those found in throttle controls, the tension spring ensures that the lever returns to its default position after being actuated. This is essential for maintaining consistent engine performance and preventing unintended throttle applications.

Throttle System

In the throttle kit, the tension spring assists in regulating the throttle position. It provides the necessary resistance to ensure that the throttle plate moves smoothly and accurately in response to driver input, thereby optimizing engine performance and fuel efficiency.

Throttle Kit

The throttle kit benefits from the tension spring by ensuring that the throttle components remain under consistent tension. This helps in achieving precise throttle control, which is vital for both performance and safety in engine operations.

Conclusion

The Cummins 3933130 Tension Spring is a vital component in commercial truck and engine systems, ensuring the smooth and efficient operation of various mechanical parts. Its design and material composition contribute to the durability, reliability, and performance of the truck and engine systems. Regular maintenance and proper troubleshooting are essential for ensuring the longevity and optimal performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.