This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

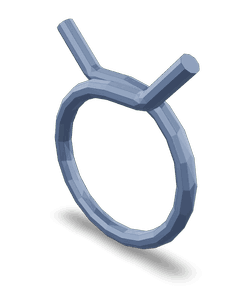

The Spring Hose Clamp 3972011 by Cummins is a component designed to secure hoses in various automotive systems. Its role is significant in maintaining the integrity and efficiency of commercial truck operations. This clamp ensures that hoses remain firmly in place, preventing leaks and ensuring that fluids are properly channeled through the system.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical devices used to hold hoses in place around fittings. They consist of a metal band with a built-in spring that provides the necessary tension to create a secure seal. These clamps are widely used in automotive and industrial applications to connect hoses to fittings, ensuring a tight and reliable connection. Their design allows for easy installation and removal, making them a popular choice for both maintenance and original equipment applications 1.

Purpose and Role in Truck Operation

The 3972011 Spring Hose Clamp plays a role in the operation of a truck by securing hoses within the system. This ensures that fluids, such as coolant, fuel, and hydraulic fluids, are properly channeled without leakage. By maintaining a secure connection, the clamp helps in preserving the integrity of the system, which is vital for the truck’s performance and longevity. It also aids in preventing potential issues that could arise from loose or disconnected hoses 2.

Key Features

The 3972011 Spring Hose Clamp is constructed from high-quality materials, ensuring durability and reliability. Its design includes a corrosion-resistant metal band and a robust spring mechanism that provides consistent tension. The clamp is engineered to accommodate a range of hose sizes, making it versatile for various applications. Additionally, its ease of installation and adjustment allows for efficient use in both maintenance and repair scenarios 3.

Benefits of Using Spring Hose Clamps

Spring hose clamps offer several advantages. They provide improved reliability by ensuring a secure connection that resists vibration and movement. Their design allows for quick and easy installation, reducing downtime during maintenance. Additionally, spring hose clamps are straightforward to maintain, requiring only periodic inspection and tightening to ensure optimal performance 4.

Installation Process

Installing the 3972011 Spring Hose Clamp involves several steps. First, ensure the hose and fitting are clean and free of debris. Slide the clamp onto the hose, positioning it over the fitting. Use a clamp plier to tighten the clamp until it creates a secure seal without over-tightening, which could damage the hose. Verify the connection by checking for leaks and ensuring the clamp is evenly tightened around the hose.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks and improper sealing. If a leak is detected, first ensure the clamp is properly tightened. If the problem persists, inspect the hose and fitting for damage or misalignment. In some cases, replacing the clamp or the hose may be necessary to resolve the issue. Regular inspections can help identify and address potential problems before they lead to more significant issues.

Maintenance Tips

To ensure the longevity and optimal performance of spring hose clamps, regular maintenance is recommended. Inspect clamps periodically for signs of corrosion, wear, or loosening. Tighten clamps as needed to maintain a secure connection. Replace clamps that show significant wear or damage to prevent leaks and ensure system integrity. Following a scheduled maintenance plan can help in identifying and addressing issues before they impact truck operation.

Compatibility and Applications

The 3972011 Spring Hose Clamp is designed for use in various truck systems, including coolant, fuel, and hydraulic systems. It is compatible with a range of hose sizes and materials, making it suitable for diverse applications. Its versatility and reliability make it a valuable component in maintaining the efficiency and safety of commercial trucks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company offers a comprehensive range of products and services designed to meet the needs of customers worldwide, ensuring they have the power to drive their success.

Spring Hose Clamp 3972011 Compatibility with Cummins Engines

The Spring Hose Clamp part number 3972011, manufactured by Cummins, is designed to fit a variety of Cummins engines. This versatile component is essential for securing hoses and ensuring a tight seal in various engine applications. Below is a detailed look at the compatibility of this part with specific Cummins engines.

6C8.3 Engine

The 6C8.3 engine is a robust and reliable option, often used in heavy-duty applications. The Spring Hose Clamp 3972011 is compatible with this engine, providing a secure fit for the necessary hoses that require a tight seal to maintain performance and efficiency.

ISC CM554 and ISL CM554 Engines

Both the ISC CM554 and ISL CM554 engines are part of Cummins’ CM554 series, known for their durability and power. The Spring Hose Clamp 3972011 fits seamlessly with these engines, ensuring that all connected hoses are properly secured. This compatibility is crucial for maintaining the integrity of the engine’s systems and preventing leaks.

QSC8.3 CM554 and QSL9 CM554 Engines

The QSC8.3 CM554 and QSL9 CM554 engines are also part of the CM554 series, designed for high-performance applications. The Spring Hose Clamp 3972011 is engineered to fit these engines, providing a reliable solution for securing hoses in demanding environments. This ensures that the engines operate efficiently and safely.

By ensuring a tight seal, the Spring Hose Clamp 3972011 helps maintain the performance and longevity of these engines, making it an essential component for any Cummins engine in the CM554 series.

Role of Part 3972011 Spring Hose Clamp in Engine Systems

The 3972011 Spring Hose Clamp is an essential component in securing hoses within various engine systems, ensuring reliable operation and maintaining system integrity.

In the breather system, the 3972011 Spring Hose Clamp is utilized to secure hoses that connect the breather to the crankcase. This connection allows for the regulated release of pressure and contaminants from the crankcase, which is vital for maintaining clean oil and efficient engine performance. The clamp ensures that the hose remains firmly in place, preventing leaks that could lead to pressure build-up or contamination within the system.

Similarly, in the crankcase system, the 3972011 Spring Hose Clamp plays a significant role in securing hoses that are part of the ventilation and pressure relief mechanisms. These hoses help in managing the crankcase pressure, which is essential for the proper functioning of the engine. By ensuring a tight and secure fit, the clamp helps in maintaining the integrity of the crankcase system, thereby contributing to the overall efficiency and longevity of the engine.

Conclusion

The 3972011 Spring Hose Clamp by Cummins is a critical component in maintaining the efficiency and reliability of commercial truck systems. Its design, compatibility with various Cummins engines, and ease of installation make it a valuable asset for both maintenance and repair scenarios. Regular maintenance and proper installation are essential to ensure the clamp’s optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.