This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

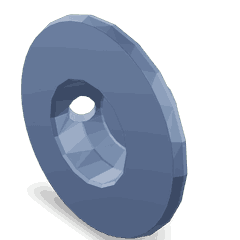

The Cummins 4076831 Spring Retainer is a component designed for use in commercial trucks. It serves a specific function within the engine’s valve train system, contributing to the overall efficiency and reliability of the truck’s operation. Understanding its purpose and role is fundamental for maintaining and optimizing the performance of commercial vehicles.

Basic Concepts of Spring Retainers

Spring retainers are mechanical components used to hold compression springs in place within various systems. In automotive applications, they are essential for maintaining the proper function of valve trains. These retainers ensure that the springs remain correctly positioned, allowing the valves to open and close as intended during engine operation. Their design and material must withstand high stresses and temperatures to ensure durability and consistent performance 1.

Purpose of the Cummins 4076831 Spring Retainer

The Cummins 4076831 Spring Retainer plays a role in the valve train system by securing the valve springs. This ensures that the valves operate correctly, opening and closing in sync with the engine’s cycles. Its function is vital for maintaining the engine’s efficiency, as it helps in achieving precise valve timing and consistent valve operation under varying engine loads and speeds.

Key Features

The Cummins 4076831 Spring Retainer is characterized by its robust material composition, typically made from high-strength steel to endure the demanding conditions within a commercial truck engine. Its design includes specific geometric features that enhance its ability to hold the springs securely in place. Additionally, it may feature unique attributes such as anti-rotation tabs to prevent the retainer from rotating within the spring, which could lead to uneven valve operation.

Benefits

Utilizing the Cummins 4076831 Spring Retainer offers several advantages. It contributes to improved engine efficiency by ensuring that the valve springs function correctly, leading to optimal valve operation. Its durable construction enhances the engine’s reliability, reducing the likelihood of unexpected failures. Furthermore, the precise design of the retainer supports consistent engine performance, which is crucial for the demanding applications of commercial trucks.

Installation and Compatibility

Proper installation of the Cummins 4076831 Spring Retainer is crucial for its effective function. The process involves ensuring that the retainer is correctly aligned with the valve springs and secured in place. Specific tools may be required to facilitate this process, ensuring that the retainer is installed without damage and fits securely. Compatibility with the engine’s design and specifications is paramount to achieve the desired performance and longevity.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 4076831 Spring Retainer involves periodic inspection for signs of wear or damage. Ensuring that it remains in good condition is key to preventing issues such as valve train noise or engine performance degradation. Common issues may include spring displacement or retainer deformation, which can be addressed through careful inspection and, if necessary, replacement of the component.

Performance Impact

The Cummins 4076831 Spring Retainer contributes to the overall performance of the truck’s engine by ensuring that the valve springs operate efficiently. This leads to improved fuel efficiency and power output, as the engine can maintain optimal valve timing and operation under various conditions. Its role in the valve train system is fundamental to achieving the engine’s designed performance levels.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Its product range is designed to meet the demanding requirements of commercial applications, ensuring reliability, efficiency, and performance 2.

Spring Retainer 4076831 Compatibility with Cummins Engines

The Spring Retainer part number 4076831, manufactured by Cummins, is designed to fit into several of their engine models. This component plays a crucial role in maintaining the integrity and functionality of the engine by securing various parts in place. Here is a detailed look at its compatibility across different Cummins engine models:

ISC CM850

The Spring Retainer 4076831 is compatible with the ISC CM850 engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The spring retainer ensures that the engine components remain securely fastened, contributing to the overall efficiency and longevity of the engine.

ISL9 CM2150 SN

Similarly, the Spring Retainer 4076831 fits the ISL9 CM2150 SN engine. This engine is part of the Cummins ISL series, which is widely recognized for its power and durability. The spring retainer’s role here is to maintain the alignment and stability of critical engine parts, ensuring smooth operation and reducing the risk of mechanical failure.

QSC8.3 CM850 (CM2850)

The Spring Retainer 4076831 is also compatible with the QSC8.3 CM850 (CM2850) engine. This engine model is known for its versatility and efficiency, making it suitable for various applications. The spring retainer’s function in this engine is to keep components in their designated positions, which is vital for maintaining the engine’s performance and reliability.

QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850)

Lastly, the Spring Retainer 4076831 is designed to fit the QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850) engines. Both of these engines are part of the Cummins QSL series, which is known for its high power output and efficiency. The spring retainer ensures that the engine components are held securely, which is essential for the engine’s overall performance and durability.

By fitting into these various engine models, the Spring Retainer 4076831 by Cummins provides a critical function in maintaining the structural integrity and operational efficiency of the engines.

Role of Part 4076831 Spring Retainer in Engine Systems

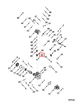

The 4076831 Spring Retainer is an integral component in the efficient operation of several engine systems, particularly those involving fuel delivery mechanisms.

In the Fuel Injection Pump, the Spring Retainer ensures that the spring components are held securely in place. This is essential for maintaining the precise pressure and timing required for fuel injection. Without proper retention, the spring could dislodge, leading to inconsistent fuel delivery and potential engine performance issues.

Within the Fuel Pump, the Spring Retainer plays a similar role. It secures the spring that is responsible for returning the pump’s plunger to its resting position after each fuel delivery cycle. This ensures that the pump operates smoothly and efficiently, without unnecessary wear or failure.

In the context of the Fuel Pump Assembly, the Spring Retainer contributes to the overall structural integrity and functionality of the assembly. It helps in maintaining the alignment and tension of the springs, which are vital for the consistent operation of the pump.

Lastly, in the Fuel Pump Head, the Spring Retainer is key in securing the springs that control the valve operations. This is important for regulating the flow of fuel into the combustion chamber, ensuring that the engine receives the correct amount of fuel at the right time.

Overall, the 4076831 Spring Retainer is a small yet significant component that contributes to the reliable and efficient operation of these fuel systems.

Conclusion

The Cummins 4076831 Spring Retainer is a critical component in the valve train system of commercial truck engines, ensuring the proper function and efficiency of the engine. Its robust design and material composition contribute to the durability and reliability of the engine, making it essential for maintaining optimal performance in demanding commercial applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.