This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

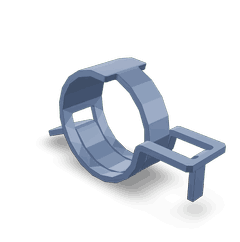

The Spring Hose Clamp 4930327, manufactured by Cummins, is a component designed for use in commercial trucks. This part secures hoses within various systems, contributing to the integrity and efficiency of hose connections in demanding environments 1.

Basic Concepts and Functionality

A spring hose clamp is a fastener used to secure hoses to fittings. It consists of a metal band with a spring mechanism that allows it to expand and contract, providing a secure grip around the hose. The clamp operates by using a screw mechanism to tighten the band around the hose, creating a seal that prevents leaks and ensures a stable connection 2.

Role in Truck Operation

The 4930327 Spring Hose Clamp is integral to the operation of commercial trucks. It is typically associated with systems such as fuel lines, coolant systems, and pneumatic systems. By securing hoses in these systems, the clamp helps maintain the flow of fluids and gases, which is vital for the truck’s performance and safety 3.

Key Features

This Cummins part features a durable material composition, typically including stainless steel or another corrosion-resistant metal. Its design attributes include a robust spring mechanism that provides consistent pressure on the hose, ensuring a secure fit. Unique characteristics of this clamp may include an ergonomic screw for easy adjustment and a protective coating to enhance durability in harsh environments.

Benefits

Using the 4930327 Spring Hose Clamp in truck maintenance and operation offers several advantages. The clamp’s design allows for ease of installation, making it a practical choice for both professional mechanics and DIY enthusiasts. Its reliability is demonstrated through consistent performance in securing hoses, reducing the risk of leaks and disconnections. The clamp’s resistance to environmental factors, such as corrosion and extreme temperatures, ensures long-term performance. Additionally, its durable construction contributes to the clamp’s longevity, making it a cost-effective solution for truck maintenance.

Troubleshooting and Maintenance

Common issues associated with spring hose clamps include loosening over time due to vibration or thermal expansion and contraction. Troubleshooting these problems involves regular inspection of the clamp for signs of wear or damage and ensuring that it is properly tightened. Maintenance practices to ensure the longevity and proper function of the clamp include periodic tightening and replacement when signs of wear are detected. Regular inspection protocols help identify potential issues before they lead to more significant problems, ensuring the clamp continues to perform its role effectively.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to manufacturing high-quality automotive components is evident in its product range, which includes the 4930327 Spring Hose Clamp. Cummins’ focus on innovation and quality ensures that its products meet the demanding requirements of commercial truck applications.

Role of Part 4930327 Spring Hose Clamp in Engine Systems

The 4930327 Spring Hose Clamp is instrumental in maintaining the integrity and efficiency of various engine systems by ensuring secure connections and preventing leaks. Its application spans across several components, each playing a distinct role in the overall functionality of the engine.

Compressor Air Inlet

In the compressor air inlet system, the Spring Hose Clamp secures the hoses that channel air into the compressor. This ensures a consistent airflow, which is essential for the compressor’s performance. A secure connection prevents air leaks, which could otherwise lead to inefficient compression and reduced system performance.

Plumbing Systems

Within the plumbing systems of both the cabin heater and the vehicle heater tube, the Spring Hose Clamp plays a significant role. It ensures that the hoses carrying coolant or heated air are firmly attached to their respective fittings. This secure attachment is vital for maintaining the pressure and temperature integrity of the fluid or air being transported, thereby ensuring efficient heating within the vehicle cabin.

Exhaust Recirculation System

In the exhaust recirculation water system, the Spring Hose Clamp is used to secure hoses that recirculate exhaust gases back into the engine. This recirculation helps in reducing emissions and improving fuel efficiency. The clamp ensures that the hoses remain connected under varying temperatures and pressures, which is essential for the system’s effectiveness in emission control.

Overall Arrangement

Across these systems, the consistent use of the Spring Hose Clamp contributes to the overall arrangement and reliability of the engine components. By providing a robust and flexible means of attachment, it allows for the necessary movement and expansion of hoses while maintaining a leak-free connection. This is particularly important in dynamic environments where engine components are subject to vibration, thermal expansion, and contraction.

Conclusion

The 4930327 Spring Hose Clamp by Cummins is a critical component for maintaining the operational integrity of various engine systems. Its robust design and reliable performance make it an essential part for securing hoses in demanding conditions, ensuring the efficiency and safety of commercial truck operations.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions: Fundamentals, Selection, Design and Application. Springer Vieweg.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones & Bartlett Learning.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.