This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

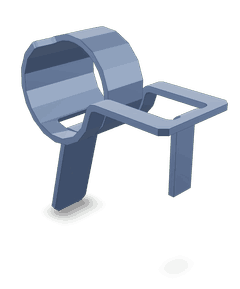

The Spring Hose Clamp 4970016, manufactured by Cummins, is a specialized component designed for commercial truck applications. This part plays a role in securing hoses and ensuring the efficient transfer of fluids within the vehicle’s systems.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical devices used to secure hoses to fittings. They consist of a metal band with a built-in spring that provides constant tension, ensuring a tight and reliable seal 1. In automotive applications, these clamps are vital for maintaining the integrity of fluid transfer systems, including coolant, fuel, and hydraulic lines. Their design allows for easy installation and removal, making them a popular choice in both original equipment and aftermarket applications 2.

Purpose of the 4970016 Spring Hose Clamp

The 4970016 Spring Hose Clamp serves to secure hoses in commercial truck applications, playing a role in maintaining the efficiency and reliability of fluid transfer systems. By providing a tight seal, it helps prevent leaks and ensures that fluids are delivered consistently to their intended destinations. This Cummins part is integral to the operation of a truck, contributing to the overall performance and longevity of the vehicle’s systems.

Key Features

The 4970016 Spring Hose Clamp features a robust design that includes a stainless steel band for durability and resistance to corrosion. Its spring mechanism is engineered to provide consistent tension, ensuring a secure fit on hoses of varying diameters. Additionally, the clamp’s design allows for easy adjustment, making it versatile for a range of applications within the commercial truck industry.

Benefits of Using the 4970016 Spring Hose Clamp

Utilizing the 4970016 Spring Hose Clamp offers several advantages. Its reliable design ensures a secure connection, reducing the risk of leaks and improving the efficiency of fluid transfer systems. The clamp’s durability and resistance to corrosion contribute to its longevity, making it a cost-effective solution for commercial truck maintenance 3. Furthermore, its ease of installation simplifies maintenance procedures, allowing for quick and efficient repairs or replacements.

Installation Process

Installing the 4970016 Spring Hose Clamp involves several steps to ensure a secure and effective connection. Begin by selecting the appropriate clamp size for the hose diameter. Place the clamp around the hose and fitting, ensuring it is aligned correctly. Use a clamp plier to tighten the clamp until it reaches the desired tension, taking care not to overtighten, which could damage the hose. Finally, inspect the connection for leaks or improper sealing, making adjustments as necessary 4.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks and improper sealing. These problems can often be traced back to incorrect installation or the use of a clamp that is not properly sized for the hose. To address leaks, first, ensure the clamp is correctly aligned and tightened to the appropriate tension. If the issue persists, consider replacing the clamp with one that better matches the hose diameter. Regular inspections can help identify and resolve these issues before they lead to more significant problems 5.

Maintenance Tips

To ensure the longevity and optimal performance of the 4970016 Spring Hose Clamp, regular maintenance is recommended. Inspect the clamp and hose connections during routine vehicle checks, looking for signs of wear, corrosion, or leaks. Clean the clamp and surrounding areas to remove any debris that could affect its performance. Replace the clamp if it shows signs of significant wear or if it no longer provides a secure seal. Adhering to these maintenance practices will help maintain the efficiency and reliability of your truck’s fluid transfer systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name among fleet operators and maintenance professionals worldwide.

Spring Hose Clamp 4970016 Compatibility with Cummins Engines

The Spring Hose Clamp 4970016, manufactured by Cummins, is a versatile component designed to fit a variety of Cummins engines. This part is essential for securing hoses in place, ensuring a tight and reliable seal that prevents leaks and maintains system integrity. Below is a detailed look at the compatibility of this hose clamp with various Cummins engines.

Compatible Engines

- 4B3.9

- 6B5.9

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

- F2.8 CM2620 F135B

- G8.3

- GTA8.3 CM558

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISBE CM2150

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

- ISL9 CM2150 SN

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

- QSL9 G CM558

- QSM11 CM876

- X12N CMMDG1 X143B

Grouping of Compatible Engines

The Spring Hose Clamp 4970016 is designed to be compatible with a broad range of Cummins engines, grouped primarily by their model series and specifications. Here’s a breakdown of the groupings:

-

B Series Engines:

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

-

F Series Engines:

- F2.8 CM2620 F135B

-

G Series Engines:

- G8.3

- GTA8.3 CM558

-

ISB/ISD Series Engines:

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISBE CM2150

- ISL9 CM2150 SN

-

ISF Series Engines:

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

-

ISM Series Engines:

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

-

QSL Series Engines:

- QSL9 G CM558

- QSM11 CM876

-

X Series Engines:

- X12N CMMDG1 X143B

This comprehensive compatibility ensures that the Spring Hose Clamp 4970016 can be used across a wide array of Cummins engines, providing a reliable solution for hose management and securing.

Role of Part 4970016 Spring Hose Clamp in Engine Systems

The 4970016 Spring Hose Clamp is an essential component in securing and maintaining the integrity of various hose connections within engine systems. Its application spans across multiple subsystems, ensuring efficient operation and preventing leaks.

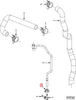

Arrangement and Plumbing

In the arrangement of engine plumbing, the 4970016 Spring Hose Clamp is utilized to secure connections between molded hoses and various engine components. This includes the attachment points at the thermostat housing, water outlet tube, and other critical junctions. By providing a tight and consistent seal, the clamp ensures that coolant and other fluids flow without interruption, maintaining optimal engine temperature and performance.

Aftertreatment and Exhaust Gas Recirculation

Within the aftertreatment system, the clamp plays a role in securing hoses associated with the exhaust gas recirculation (EGR) module. It ensures that the recirculated exhaust gases are effectively routed back into the intake system, reducing emissions and improving fuel efficiency. The clamp’s reliable hold is vital in withstanding the high temperatures and pressures inherent in the EGR process.

Crankcase and Breather Systems

The 4970016 Spring Hose Clamp is also integral in the crankcase breather system. It secures the breather tube, allowing gases to escape from the crankcase without causing pressure build-up. This is essential for maintaining engine lubrication and preventing oil contamination. Additionally, in systems where an exhaust recirculation water plumbing arrangement is present, the clamp ensures that water is correctly circulated to aid in cooling and emission control.

Turbocharger and Recirculation

In turbocharged engines, the clamp is used in the plumbing associated with the turbocharger recirculation system. It ensures that the recirculated air is properly managed, contributing to the turbocharger’s efficiency and longevity. The clamp’s durability under high-pressure conditions is key to the system’s reliable operation.

Overall, the 4970016 Spring Hose Clamp is a versatile component that enhances the functionality and reliability of various engine subsystems by providing secure and leak-proof connections.

Conclusion

The 4970016 Spring Hose Clamp by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its robust design, ease of installation, and compatibility with a wide range of Cummins engines make it an invaluable tool for ensuring the efficiency and reliability of fluid transfer systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of commercial vehicles.

-

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ -

Cummins Inc. Service Manual (5504160).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.