5269352

Spring Hose Clamp

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Spring Hose Clamp, identified by Part #5269352, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This clamp is integral to the efficient operation of various truck systems, ensuring secure connections in hose assemblies. Its design and functionality are tailored to meet the demanding requirements of commercial truck applications.

Basic Concepts and Functionality

A Spring Hose Clamp is a mechanical device used to secure hoses in automotive and industrial systems. It consists of a metal band with a built-in spring mechanism that allows it to expand and contract, providing a firm grip around the hose. The clamp operates by tightening around the hose when the band is twisted, creating a secure seal that prevents leaks and ensures the integrity of the fluid transfer system 1.

Purpose of the Spring Hose Clamp in Truck Operations

In truck operations, the Spring Hose Clamp plays a significant role in maintaining the efficiency and reliability of various systems. It is commonly used in fuel, coolant, and brake systems, where secure hose connections are vital. By providing a tight and consistent grip, the clamp helps in preventing hose disconnections and leaks, which can lead to system failures or inefficiencies 2.

Key Features

The Spring Hose Clamp by Cummins is designed with several key features that enhance its performance. It is typically made from durable materials such as stainless steel, which offers resistance to corrosion and wear. The design includes a spring mechanism that allows for easy installation and adjustment, ensuring a snug fit around various hose diameters. Additionally, the clamp features a protective coating to further enhance its durability and resistance to environmental factors 3.

Benefits of Using a Spring Hose Clamp

Incorporating a Spring Hose Clamp in truck maintenance and operations offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of use, facilitated by the spring mechanism, allows for quick installation and adjustment, saving time during maintenance procedures. Moreover, the secure fit provided by the clamp enhances the efficiency of fluid transfer systems, contributing to the overall performance of the truck.

Installation and Usage Guidelines

Proper installation of the Spring Hose Clamp involves several steps. First, the correct size clamp should be selected to match the hose diameter. The clamp is then positioned around the hose and the band is twisted to tighten it securely in place. It is important to ensure that the clamp is not over-tightened, as this can damage the hose. Regular checks should be performed to ensure the clamp remains secure and the hose is not leaking.

Troubleshooting and Maintenance

Common issues with Spring Hose Clamps include loosening over time due to vibration or thermal expansion, and corrosion in harsh environments. Troubleshooting involves checking for signs of wear or damage, ensuring the clamp is properly tightened, and replacing it if necessary. Regular maintenance, such as cleaning and inspecting the clamp and hose for signs of wear, can help prevent issues and ensure optimal performance.

Safety Considerations

When working with Spring Hose Clamps, it is important to follow safety guidelines to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and the system is depressurized before working on hoses, and using the correct tools for installation and adjustment. Adhering to these safety practices helps ensure a safe working environment and compliance with industry standards.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of commercial applications.

Spring Hose Clamp 5269352 Compatibility with Cummins Engines

The Spring Hose Clamp 5269352, manufactured by Cummins, is a versatile component designed to fit a variety of Cummins engines. This clamp is essential for securing hoses in high-pressure and high-temperature environments, ensuring a reliable and leak-free connection.

Compatible Engines

- B4.5 CM2350 B129B

- D4.0 CM2620 D103B

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- ISB4.5 CM2350 B104

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

- R2.8 CM2220 R101B

Grouping by Engine Series

-

CM2350 Series:

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

- QSF3.8 CM2350 F107

- F3.8 CM2350 F120B

-

CM2620 Series:

- D4.0 CM2620 D103B

- F2.8 CM2620 F135B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

-

CM2220 Series:

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- R2.8 CM2220 R101B

-

CM2880 Series:

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

- QSF3.8 CM2880 F112

The Spring Hose Clamp 5269352 is engineered to provide a secure fit across these diverse engine models, ensuring optimal performance and longevity in demanding applications.

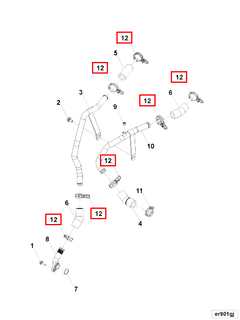

Role of Part 5269352 Spring Hose Clamp in Engine Systems

The part 5269352 Spring Hose Clamp is integral to maintaining the integrity and efficiency of various engine systems by ensuring secure connections and preventing leaks. In the breather system, this clamp is used to connect the breather hoses, which release pressure from the crankcase. Proper sealing here is essential to prevent oil vapors from escaping, which could lead to contamination and reduced engine performance.

In the crankcase ventilation system, the clamp secures hoses that allow for the safe release of gases from the crankcase. This helps in maintaining optimal pressure levels within the crankcase, contributing to the overall efficiency and longevity of the engine.

For the Exhaust Gas Recirculation (EGR) system, the clamp plays a role in securing the plumbing that recirculates a portion of the exhaust gases back into the intake manifold. This reduces nitrogen oxides (NOx) emissions, contributing to a cleaner and more environmentally friendly operation.

In turbocharger systems, the clamp is employed in various plumbing applications. It secures the hoses in the turbocharger oil system, ensuring that oil is efficiently circulated to lubricate and cool the turbocharger. Additionally, it is used in the turbocharger oil drain connection, facilitating the removal of used oil and maintaining the turbocharger’s operational integrity.

Lastly, in the turbocharger plumbing, the clamp is vital for securing all hoses that transport air, oil, and other fluids. This ensures that the turbocharger operates within its designed parameters, enhancing engine performance and reliability.

Conclusion

The Spring Hose Clamp 5269352 is a critical component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its robust design, ease of use, and compatibility with a wide range of engine models make it an essential part for ensuring the efficiency and reliability of various engine systems. Proper installation, regular maintenance, and adherence to safety guidelines are key to maximizing the benefits of this Cummins part.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Caines, Arthur J, Haycock, Roger F, and Hillier, John E. Automotive Lubricants Reference Book. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.