5305658

Spring Hose Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Spring Hose Connector, identified by Part #5305658, is a component manufactured by Cummins, a prominent name in the commercial truck industry. This connector is integral to the fluid systems of commercial trucks, ensuring efficient and reliable operation. Cummins, known for its robust and dependable parts, provides this connector as part of its extensive range of truck components 1.

Basic Concepts and Functionality

A Spring Hose Connector is a device used to join hoses in a truck’s fluid system. It operates by utilizing a spring mechanism to create a secure and flexible connection between hoses. This connector plays a role in maintaining the integrity of fluid dynamics within the truck’s system, ensuring that fluids are transported efficiently and without leaks 2.

Purpose of the Spring Hose Connector

The Spring Hose Connector (Part #5305658) serves a specific function in the operation of a truck. It is designed to connect hoses in a manner that allows for fluid flow while accommodating the movement and vibrations typical in a truck’s operating environment. This connector ensures a stable connection, which is vital for the consistent performance of the truck’s fluid systems.

Key Features

The Spring Hose Connector is characterized by several key features that enhance its performance and durability. Its design incorporates a spring mechanism that provides flexibility and a secure fit. The materials used in its construction are chosen for their strength and resistance to the elements, ensuring longevity and reliability in demanding conditions. Additionally, the connector may feature unique attributes such as corrosion-resistant coatings or specialized fittings that further improve its functionality.

Benefits

The advantages of using the Spring Hose Connector include improved reliability in fluid system connections, which contributes to the overall efficiency of the truck. Its design allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, the connector’s durability and resistance to wear and tear offer maintenance benefits, potentially lowering the frequency of replacements and repairs.

Installation Process

Installing the Spring Hose Connector involves several steps to ensure a proper and secure fit. Begin by preparing the hose ends for connection, ensuring they are clean and free from debris. Next, align the connector with the hose ends and use the spring mechanism to create a tight seal. It is important to follow manufacturer guidelines to avoid common pitfalls such as over-tightening, which can damage the connector or hoses.

Troubleshooting and Maintenance

Identifying common issues with the Spring Hose Connector may involve checking for leaks, examining the spring mechanism for wear, and ensuring the connector remains securely attached to the hoses. Routine maintenance can include inspecting the connector for signs of corrosion or damage and cleaning it to remove any buildup that could affect its performance. Replacement should be considered if the connector shows significant wear or if it fails to create a secure connection.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 3.

Compatibility with Cummins Engines

This part is designed to fit a variety of Cummins engines. It is integral to the proper functioning of the fuel and coolant systems in these engines, ensuring secure and leak-free connections.

Compatibility with Specific Engine Models

- 15N CM2380 M104B

- F3.8 CM2350 F128C

- ISC CM2150

- ISC8.3 CM2250

- ISL CM2150

- ISL G CM2180

- ISL9 CM2250

- QSB4.5 CM2250 EC

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSC9 CM2250/QSL9 CM2250

- QSF3.8 CM2350 F107

- QSK19 CM2350 K105

- QSL9 CM2250

- QSL9 CM2350 L102

Grouping of Compatible Engines

The Spring Hose Connector 5305658 is compatible with the following groups of engines:

- ISC Series: ISC CM2150, ISC8.3 CM2250

- ISL Series: ISL CM2150, ISL G CM2180, ISL9 CM2250

- QSB Series: QSB4.5 CM2250 EC, QSB6.7 CM2250, QSB6.7 CM2350 B105

- QSC/QSL Series: QSC9 CM2250/QSL9 CM2250, QSL9 CM2250, QSL9 CM2350 L102

- Other Models: 15N CM2380 M104B, F3.8 CM2350 F128C, QSF3.8 CM2350 F107, QSK19 CM2350 K105

This part is engineered to ensure a snug fit and reliable performance across these diverse engine models, facilitating efficient fluid transfer and maintaining system integrity.

Role of Part 5305658 Spring Hose Connector in Engine Systems

The 5305658 Spring Hose Connector is a component in various engine systems, facilitating efficient and secure connections between different parts. Its application spans across several key areas within engine setups, ensuring optimal performance and reliability.

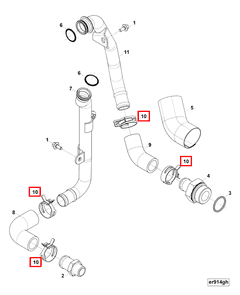

Compressor Air Inlet Arrangement

In the compressor air inlet arrangement, the 5305658 Spring Hose Connector is utilized to join the air intake hose to the compressor. This connection is vital for maintaining a sealed pathway for air to enter the compressor, ensuring that the air supply is consistent and free from leaks. The spring mechanism within the connector allows for flexibility and vibration dampening, which is particularly important in high-stress environments where the compressor operates.

Crankcase Breather Arrangement

For the crankcase breather arrangement, the Spring Hose Connector plays a role in linking the breather hose to the crankcase. This setup helps in venting pressure build-up within the crankcase, which is essential for maintaining engine health. The connector’s design ensures a tight seal, preventing any contaminants from entering the crankcase while allowing gases to escape efficiently.

Hardware Kit Integration

When included in a hardware kit, the 5305658 Spring Hose Connector is often used to assemble various hose connections within the engine system. Its versatility allows it to be employed in multiple applications, from fuel lines to coolant systems, ensuring that all connections are secure and capable of withstanding the operational pressures and temperatures of the engine.

Plumbing for Exhaust Recirculation Air

In the context of plumbing for exhaust recirculation air, the Spring Hose Connector is instrumental in connecting the exhaust recirculation (EGR) valve to the intake manifold. This connection is part of the EGR system, which recirculates a portion of the exhaust gas back into the intake to reduce emissions. The connector ensures that the recirculated gases are delivered smoothly and without leaks, contributing to the overall efficiency of the EGR system.

Plumbing for Exhaust Recirculation Water

Similarly, for plumbing for exhaust recirculation water systems, the 5305658 Spring Hose Connector is used to link the water recirculation components. This is particularly relevant in engines equipped with water-cooled EGR systems, where water is used to cool the recirculated exhaust gases before they enter the intake. The connector’s robust design ensures that the water lines remain intact under pressure, facilitating effective cooling and reducing the risk of system failure.

Conclusion

In summary, the 5305658 Spring Hose Connector is a versatile and reliable component that enhances the functionality and durability of various engine systems. Its application across different arrangements and plumbing setups underscores its importance in maintaining the integrity and performance of engine operations.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.