This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Spring Hose Clamp 5305660 is a product manufactured by Cummins, a well-established name in the commercial truck industry. This clamp is designed for use in commercial trucks, where it plays a significant role in the secure attachment of hoses within various systems.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical fasteners used to secure hoses to fittings. They consist of a metal band with a built-in spring that provides constant tension to maintain a tight seal. In automotive applications, these clamps are vital for ensuring that hoses remain firmly attached, preventing leaks and maintaining the integrity of fluid systems 1.

Purpose of the 5305660 Spring Hose Clamp

The 5305660 Spring Hose Clamp is integral to the operation of a truck by securing hoses in critical systems such as the cooling, fuel, and hydraulic systems. It ensures that hoses remain connected under various operating conditions, which helps maintain system efficiency and safety. By providing a reliable seal, the clamp contributes to the overall performance and longevity of the truck’s systems 2.

Key Features

The 5305660 Spring Hose Clamp is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes a robust spring mechanism that offers consistent tension, which is crucial for maintaining a secure fit. Additionally, the clamp features ease of installation, allowing for quick and efficient attachment to hoses 3.

Benefits

Using the 5305660 Spring Hose Clamp offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation saves time during maintenance procedures, and its reliable performance under various conditions contributes to the overall efficiency of the truck’s systems 4.

Installation Process

To install the 5305660 Spring Hose Clamp, first, ensure the hose and fitting are clean and free of debris. Place the clamp over the hose and position it around the fitting. Use a clamp plier to tighten the clamp until it achieves the desired tension, ensuring a secure fit without over-tightening, which could damage the hose.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks due to improper tension or damage to the clamp. To address these problems, check the clamp’s tension and ensure it is correctly installed. If the clamp is damaged, replace it with a new one to maintain system integrity.

Maintenance Tips

Regular maintenance of the 5305660 Spring Hose Clamp involves inspecting it for signs of wear or corrosion. Clean the clamp and surrounding areas to prevent buildup that could affect its performance. Periodically check the tension to ensure it remains secure, and replace the clamp if any damage is detected.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovative solutions and commitment to quality. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of the commercial truck industry.

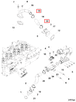

Spring Hose Clamp 5305660 Compatibility with Cummins Engines

The Spring Hose Clamp 5305660, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines, ensuring secure and reliable connections for hoses and other components. This clamp is particularly suited for use in the following engines:

- F3.8 CM2350

- F128C

- QSB6.7 CM2350 B105

- QSF3.8 CM2350 F107

These engines, while distinct in their specifications and applications, share common design elements that make the 5305660 Spring Hose Clamp an ideal fit. The clamp’s robust construction and precise engineering ensure it can withstand the operational stresses of these engines, providing a dependable solution for maintaining hose integrity.

When used with the F3.8 CM2350 and QSF3.8 CM2350 F107 engines, the 5305660 clamp offers exceptional flexibility and durability, crucial for the demanding environments these engines typically operate in. Similarly, for the F128C and QSB6.7 CM2350 B105 engines, the clamp’s design ensures it can handle the specific pressures and temperatures associated with these models, maintaining the integrity of hose connections over extended periods.

Role of Part 5305660 Spring Hose Clamp in Engine Systems

The Part 5305660 Spring Hose Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. In plumbing applications, this clamp is utilized to maintain a tight seal around hoses that transport fluids such as coolant, fuel, or hydraulic fluid. Its spring mechanism allows for easy installation and adjustment, accommodating different hose diameters and ensuring a consistent seal that prevents leaks and maintains system pressure.

In exhaust recirculation systems, the Spring Hose Clamp plays a significant role by securing hoses that reroute exhaust gases back into the intake manifold. This process helps reduce emissions and improve fuel efficiency. The clamp’s robust design withstands the high temperatures and pressures associated with exhaust gases, ensuring a reliable connection that contributes to the overall performance and longevity of the engine.

For air systems, particularly those involving air intake or ventilation, the Spring Hose Clamp ensures that hoses remain firmly attached to their respective fittings. This is vital for maintaining the correct airflow within the engine, which is necessary for optimal combustion and performance. The clamp’s flexibility and durability make it well-suited for the dynamic conditions present in air systems, where vibrations and temperature fluctuations are common.

Conclusion

The 5305660 Spring Hose Clamp by Cummins is a versatile and reliable component that enhances the functionality and efficiency of engine systems by providing secure and leak-proof connections across a variety of applications. Its robust construction, ease of installation, and compatibility with various Cummins engines make it an indispensable part for maintaining the integrity of hose connections in commercial trucks.

-

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Duffy, Owen C., and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.