This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Spring Hose Clamp 5308088, manufactured by Cummins, is a vital component in the maintenance and operation of commercial trucks. This clamp ensures the secure attachment of hoses in various systems, contributing to the efficiency and reliability of truck operations.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are essential in automotive and industrial applications for creating secure connections between hoses and fittings. They apply consistent pressure around the hose to ensure a tight seal, preventing leaks. These clamps are commonly used in fuel, coolant, and pneumatic systems, where maintaining a secure and leak-free connection is critical for system efficiency and safety 1.

Purpose of the 5308088 Spring Hose Clamp

This Cummins part secures hoses in various systems such as fuel, coolant, and pneumatic systems. Its application ensures that hoses remain firmly attached to their fittings, contributing to the uninterrupted flow of fluids and gases, thereby enhancing the overall efficiency and reliability of the truck’s systems 2.

Key Features

The 5308088 Spring Hose Clamp is characterized by several key features that enhance its functionality. It is typically made from durable materials such as stainless steel, providing resistance to corrosion and ensuring longevity. The design includes a spring mechanism that allows for easy adjustment and a secure fit around the hose. Additionally, it may feature a protective coating to further guard against environmental factors and enhance performance 3.

Benefits

Using the 5308088 Spring Hose Clamp offers several advantages. Its robust construction and secure clamping mechanism contribute to improved reliability in hose connections. The ease of installation is another benefit, as the spring design allows for quick and efficient attachment without the need for additional tools. Moreover, its durability reduces the frequency of replacements, offering maintenance benefits over time 4.

Installation Process

Installing the 5308088 Spring Hose Clamp involves several steps to ensure a proper and secure fit. Begin by selecting the appropriate clamp size for the hose diameter. Place the clamp around the hose, ensuring it is positioned correctly in relation to the fitting. Use a clamp plier to tighten the clamp until it achieves the desired tension, ensuring a snug fit without over-tightening, which could damage the hose. Finally, verify the connection by checking for leaks or looseness 5.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks, loose connections, and clamp failure. Leaks may occur due to improper installation or wear and tear on the clamp or hose. Loose connections can result from insufficient tension during installation. Clamp failure might be due to corrosion or physical damage. Addressing these issues involves re-tightening the clamp, replacing worn components, or adjusting the installation technique to ensure a secure and leak-free connection 6.

Maintenance Tips

Regular maintenance of the 5308088 Spring Hose Clamp is crucial for ensuring longevity and optimal performance. Inspect the clamp and hose connections at regular intervals for signs of wear, corrosion, or leaks. Clean the clamp and surrounding areas to remove any debris that could affect performance. Replace the clamp if it shows signs of significant wear or if the hose it secures needs replacement. Adhering to these maintenance practices will help maintain the efficiency and reliability of the truck’s systems 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted name in the industry 8.

Cummins Engine Part 5308088: Spring Hose Clamp Compatibility

The Spring Hose Clamp part number 5308088, manufactured by Cummins, is a versatile component designed to fit a variety of Cummins engines. This part is essential for securing hoses in place, ensuring a tight and reliable connection that can withstand the rigors of engine operation.

Compatibility with Specific Cummins Engines

The Spring Hose Clamp part 5308088 is compatible with several Cummins engine models, including:

- B4.5 CM2350 B129B

- F3.8 CM2350 F128C

- ISB4.5 CM2350 B104

These engines, while differing in specific configurations and applications, share common design elements that allow the 5308088 clamp to fit seamlessly. The clamp’s design ensures it can be used across these models without modification, providing a standardized solution for hose management.

Compatibility with Other Cummins Engines

In addition to the above models, the Spring Hose Clamp part 5308088 is also compatible with:

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

- QSF3.8 CM2350 F107

These engines, while part of different series, also benefit from the clamp’s ability to provide a secure and durable connection for various hoses. The compatibility across these models highlights the clamp’s versatility and its importance in maintaining the integrity of hose connections in different engine environments.

Grouping for Ease of Use

For ease of use, the engines can be grouped based on their series and displacement:

-

CM2350 Series:

- B4.5 CM2350 B129B

- F3.8 CM2350 F128C

- ISB4.5 CM2350 B104

- QSF3.8 CM2350 F107

-

CM2880 Series:

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

This grouping helps users quickly identify which engines are compatible with the 5308088 Spring Hose Clamp, facilitating efficient maintenance and repair processes.

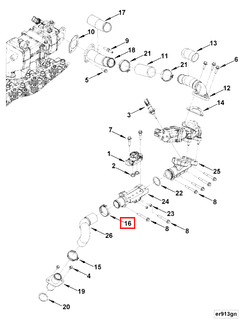

Role of Part 5308088 Spring Hose Clamp in Engine Systems

The part 5308088 Spring Hose Clamp is instrumental in ensuring the secure and efficient operation of various engine components. In the context of an engine’s arrangement, this clamp plays a significant role in maintaining the integrity of hose connections, which are vital for the proper functioning of the system.

When considering the crankcase breather system, the Spring Hose Clamp ensures that hoses are tightly sealed, preventing any unwanted leaks that could lead to contamination or reduced efficiency. This is particularly important in maintaining the correct pressure within the crankcase, which is essential for optimal engine performance.

In the realm of plumbing within engine systems, the clamp is used to secure hoses that transport fluids such as coolant, oil, or fuel. Its reliable grip helps in preventing disconnections or leaks, which could otherwise result in system failures or hazardous conditions.

For the exhaust recirculation air system, the Spring Hose Clamp is equally important. It ensures that the hoses involved in recirculating exhaust gases back into the engine are securely fastened. This not only enhances the efficiency of the recirculation process but also contributes to reducing emissions by ensuring that the system operates as designed.

Overall, the part 5308088 Spring Hose Clamp is a fundamental component in various engine systems, providing the necessary security and reliability for hose connections across different applications.

Conclusion

The 5308088 Spring Hose Clamp by Cummins is a critical component for maintaining the integrity and efficiency of hose connections in various engine systems. Its robust construction, ease of installation, and compatibility with a wide range of Cummins engines make it an essential part for ensuring the reliable operation of commercial trucks. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of the vehicle’s systems.

-

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ -

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358563.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358563.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358563.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.