This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

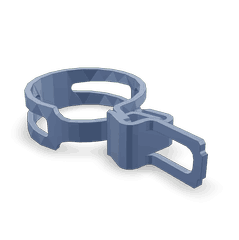

The Spring Hose Clamp Assembly 5334798 by Cummins is a component designed to secure hoses in various automotive systems. Its purpose is to maintain the integrity of hose connections, ensuring that fluids and gases are transported efficiently and safely within the system. This assembly is significant in the operation of commercial trucks, where reliable fluid and gas transport is vital for performance and safety 1.

Basic Concepts of Spring Hose Clamp Assembly

A Spring Hose Clamp Assembly is a device used to hold hoses in place by applying consistent pressure around the hose’s circumference. It typically consists of a metal band with a spring mechanism that allows for easy adjustment and secure fitting. These assemblies are widely applied in automotive systems to connect hoses in fuel, coolant, and pneumatic systems, among others 2.

Purpose of the 5334798 Spring Hose Clamp Assembly

This Cummins part plays a role in the operation of a truck by securing hoses and maintaining the integrity of the system. It ensures that hoses remain firmly in place, preventing leaks and ensuring that fluids and gases are transported as intended. This assembly contributes to the overall reliability and efficiency of the truck’s systems.

Key Features

The 5334798 Spring Hose Clamp Assembly features a durable material composition, typically including stainless steel or another corrosion-resistant metal, which enhances its longevity and performance. Its design includes a spring mechanism that allows for easy adjustment and a secure fit on various hose sizes. Additionally, it may have unique attributes such as a protective coating to resist environmental factors and ensure consistent performance over time.

Benefits

This part offers several benefits, including improved reliability in hose connections, ease of installation due to its adjustable design, and durability under various operating conditions. Its robust construction ensures that it can withstand the rigors of commercial truck operation, providing long-lasting performance.

Installation Process

To install the Spring Hose Clamp Assembly, first, ensure the hose is clean and free of debris. Place the clamp around the hose, ensuring it is centered. Use the appropriate tool to tighten the clamp until it reaches the desired tension, ensuring a secure fit without over-tightening, which could damage the hose. Follow best practices for installation to ensure optimal performance and longevity of the assembly.

Troubleshooting Common Issues

Common problems with Spring Hose Clamp Assemblies may include leaks due to improper installation or wear and tear over time. To address these issues, inspect the clamp for proper tension and alignment. If leaks persist, the clamp may need to be replaced. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

Regular maintenance of the 5334798 Spring Hose Clamp Assembly is recommended to ensure longevity and consistent performance. Inspect the assembly for signs of wear, corrosion, or damage at regular intervals. Replace the clamp if it shows signs of significant wear or if it no longer provides a secure fit. Following these maintenance tips can help ensure the assembly continues to perform reliably.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles. The 5334798 Spring Hose Clamp Assembly is a testament to Cummins’ commitment to quality and reliability in the automotive sector 3.

Compatibility with Cummins Engines

The Spring Hose Clamp Assembly 5334798 is designed to fit a variety of Cummins engines, ensuring a tight seal and maintaining the integrity of the engine’s cooling and fuel systems.

B4.5 CM2350 Engines

- B4.5 CM2350 B129B

- B4.5 CM2350 B104

D4.0 CM2620 Engines

- D4.0 CM2620 D103B

F3.8 CM2350 Engines

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- QSF3.8 CM2350 F107

F3.8 CM2620 Engines

- F3.8 CM2620 F137B

F4.5 CM2620 Engines

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

By ensuring a secure fit, this part helps maintain the performance and reliability of these engines, preventing leaks and ensuring that the engine operates efficiently.

Role in Engine Systems

The 5334798 Spring Hose Clamp Assembly is utilized in the breather system, which includes the crankcase and breather tube. In the breather system, the clamp assembly ensures a tight and reliable seal between the breather tube and the crankcase. This seal is important for the proper ventilation of the crankcase, allowing it to release excess pressure and contaminants that accumulate during engine operation. The clamp assembly helps prevent leaks, which could lead to reduced engine efficiency and potential damage.

Additionally, the clamp assembly facilitates easy maintenance and replacement of the breather tube. Its design allows for quick disconnection and reconnection, which is beneficial during routine inspections or when performing repairs. This feature ensures that the breather system can be efficiently managed without requiring complex tools or procedures.

Conclusion

The 5334798 Spring Hose Clamp Assembly by Cummins is a vital component in maintaining the integrity and efficiency of hose connections in commercial truck systems. Its durable construction, ease of installation, and compatibility with various Cummins engines make it an essential part for ensuring reliable operation and performance. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.