This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

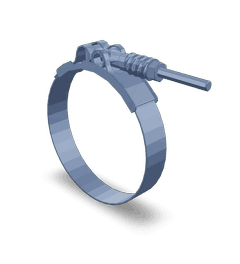

The Spring Hose Clamp (Part #5566160) by Cummins is a specialized component designed to secure hoses in various truck systems. Its purpose is to ensure a tight and reliable connection, which is vital for the efficient operation of commercial trucks. This clamp is integral to maintaining the integrity of fluid transfer systems, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical fasteners used to secure hoses to fittings. They consist of a metal band with a built-in spring mechanism that allows for easy adjustment and secure clamping. These clamps are widely used in automotive and industrial applications to maintain airtight and fluid-tight connections. Their design ensures that hoses remain firmly attached under varying conditions, preventing leaks and ensuring consistent system performance 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation of commercial trucks by securing hoses in critical systems such as the cooling, fuel, and hydraulic systems. It ensures that hoses remain connected under dynamic conditions, such as vibrations and temperature fluctuations, which are common in truck operations. This clamp is applied in various truck systems to maintain secure connections, ensuring the efficient transfer of fluids and gases essential for truck functionality 2.

Key Features

The 5566160 Spring Hose Clamp is constructed from high-quality materials, typically stainless steel, which provides excellent corrosion resistance and durability. Its design includes a robust spring mechanism that allows for easy installation and adjustment. The clamp features a serrated inner surface that grips the hose firmly, preventing slippage. Additionally, it is designed to accommodate a range of hose diameters, making it versatile for various applications 3.

Benefits

Using the 5566160 Spring Hose Clamp offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation allows for quick setup without specialized tools. The secure clamping mechanism maintains a tight seal, preventing leaks and ensuring consistent system performance. Furthermore, its corrosion-resistant properties make it suitable for use in harsh environments, common in commercial truck operations 4.

Installation Process

Proper installation of the 5566160 Spring Hose Clamp involves several steps. First, ensure the hose and fitting are clean and free of debris. Place the clamp around the hose, ensuring it is positioned correctly on the fitting. Use a clamp plier to tighten the clamp until it reaches the desired tension, ensuring a secure fit without over-tightening, which could damage the hose. Verify the connection by checking for leaks and ensuring the clamp is evenly tightened 5.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks and improper sealing. If a leak is detected, first ensure the clamp is tightened correctly. If the problem persists, inspect the hose and fitting for damage. Replace any damaged components as necessary. Additionally, ensure the clamp is the correct size for the hose diameter to achieve a proper seal 6.

Maintenance Tips

Regular maintenance of the 5566160 Spring Hose Clamp is crucial for ensuring longevity and optimal performance. Inspect the clamp periodically for signs of wear or corrosion. Check the tension of the clamp to ensure it remains secure. Replace the clamp if it shows significant wear or if the hose it secures is replaced. Following these maintenance practices will help maintain the efficiency and reliability of the truck’s fluid transfer systems 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the commercial truck industry. The company offers a wide range of products and services, including engines, powertrains, and aftermarket parts, designed to meet the demanding needs of commercial transportation. Cummins is known for its commitment to customer satisfaction and technological advancement, making it a trusted name in the industry 8.

Engines Compatible with Spring Hose Clamp 5566160

B5.9 Series

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

B6.7 Series

- B6.7 CM2250

C Series

- C GAS PLUS CM556

ISB Series

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISBE Series

- ISBE CM800

QSB Series

- QSB3.9 30 CM550

- QSB3.9 CM2880 B138

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM2880 B139

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

This clamp is engineered to fit snugly around hoses, providing a reliable grip that can withstand the rigors of engine operation. Its design ensures that it can be easily installed and removed, making it a convenient choice for maintenance and repairs. The compatibility of this clamp with a wide range of Cummins engines underscores its versatility and importance in maintaining the performance and reliability of these engines 9.

Role of Part 5566160 Spring Hose Clamp in Engine Systems

The 5566160 Spring Hose Clamp is instrumental in maintaining the integrity and efficiency of various engine systems by securing hoses and ensuring a tight, leak-free connection.

Air Intake Hose

In the air intake system, the Spring Hose Clamp is used to secure the air intake hose to the throttle body or the air filter housing. This ensures that the air entering the engine is clean and metered accurately, which is essential for optimal combustion and engine performance. The clamp’s ability to provide a consistent and reliable seal helps prevent air leaks, which can lead to inefficient air-fuel mixture and reduced engine efficiency.

By maintaining a secure connection, the Spring Hose Clamp contributes to the overall durability and performance of the air intake system, ensuring that the engine receives the necessary airflow for combustion without any disruptions 10.

Conclusion

The 5566160 Spring Hose Clamp by Cummins is a critical component in ensuring the reliability and efficiency of commercial truck systems. Its robust design, ease of installation, and compatibility with a wide range of Cummins engines make it an indispensable part for maintaining secure and leak-free connections in various engine systems. Regular maintenance and proper installation are essential to maximize the performance and longevity of this clamp, contributing to the overall reliability of commercial trucks.

-

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6310310, Engine: GTA855GCE CMEICS N110C.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6310310, Engine: GTA855GCE CMEICS N110C.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.