This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Spring Hose Clamp Part #3092253 by Cummins is a component designed to secure hoses in various automotive systems. Its role is significant in ensuring the efficient operation of commercial trucks by maintaining secure connections and proper fluid flow within the system.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical devices used to create a secure connection between a hose and a fitting. They consist of a metal band with a built-in spring that provides constant tension, ensuring a tight seal. These clamps are widely used in automotive and industrial applications to manage fluid transfer systems, including coolant, fuel, and hydraulic lines 1.

Purpose of the Spring Hose Clamp in Truck Operation

In the operation of a truck, the Spring Hose Clamp Part #3092253 plays a role by securing hoses to their respective fittings. This ensures that fluids such as coolant, fuel, or hydraulic fluid are transferred efficiently and without leakage. Proper fluid flow is vital for the truck’s performance, as it ensures that all systems receive the necessary fluids to operate correctly 2.

Key Features of the Cummins Spring Hose Clamp

The Cummins Spring Hose Clamp Part #3092253 is characterized by several specific features that enhance its performance. It is constructed from durable materials, ensuring longevity and resistance to corrosion. The design includes a robust spring mechanism that provides consistent tension, maintaining a secure fit over time. Additionally, the clamp is engineered to accommodate a range of hose sizes, offering versatility in application 3.

Benefits of Using the Cummins Spring Hose Clamp

Utilizing the Cummins Spring Hose Clamp offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation allows for quick setup without specialized tools, enhancing efficiency during maintenance procedures. Furthermore, its reliable performance under various operating conditions makes it a valuable component in ensuring the consistent operation of truck systems.

Installation and Usage Guidelines

To install the Spring Hose Clamp Part #3092253, first, ensure the hose and fitting are clean and free of debris. Slide the clamp onto the hose, positioning it near the fitting. Use a clamp plier to tighten the clamp until it securely holds the hose in place without over-tightening, which could damage the hose. Regular checks should be performed to ensure the clamp remains tight and the connection secure.

Troubleshooting Common Issues

Common issues with spring hose clamps include leaks due to improper installation or wear over time. To address these problems, inspect the clamp for signs of corrosion or damage. Ensure the clamp is correctly sized for the hose and fitting. If leaks persist, consider replacing the clamp or the hose to maintain system integrity.

Maintenance Tips

Regular maintenance of the Spring Hose Clamp involves periodic inspection for signs of wear or corrosion. It is advisable to follow a scheduled maintenance plan that includes checking the tightness of the clamp and the condition of the hose. Replacement should be considered if the clamp shows significant wear or if the hose exhibits signs of degradation to ensure ongoing system reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for professionals in the automotive and heavy-duty truck sectors.

Spring Hose Clamp 3092253 Compatibility with Cummins Engines

The Spring Hose Clamp part number 3092253, manufactured by Cummins, is designed to fit a variety of Cummins engines. This component is essential for securing hoses in place, ensuring that there are no leaks or disconnections that could compromise engine performance or safety.

Compatibility with Specific Engine Models

6C8.3

The Spring Hose Clamp 3092253 is compatible with the 6C8.3 engine. This engine is known for its robust design and reliability, often used in various industrial applications. The clamp ensures that hoses remain securely attached under varying operational conditions, maintaining the integrity of the engine’s systems.

QST30 CM2350 T101 and QST30 CM552

Both the QST30 CM2350 T101 and QST30 CM552 engines benefit from the use of the Spring Hose Clamp 3092253. These engines are part of the QST30 series, which is renowned for its efficiency and durability. The clamp’s design allows for easy installation and removal, making it a practical choice for maintenance and repairs. It ensures that the hoses are held firmly in place, preventing any potential issues that could arise from loose connections.

General Application

The Spring Hose Clamp 3092253 is engineered to provide a secure fit across multiple engine models. Its design accommodates the varying diameters and materials of hoses used in these engines, ensuring a tight and reliable seal. This compatibility is crucial for maintaining the overall performance and longevity of the engine systems.

Role of Part 3092253 Spring Hose Clamp in Engine Systems

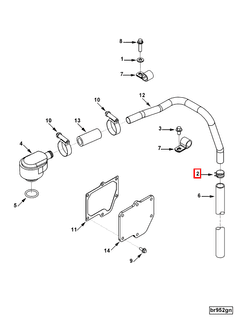

The Part 3092253 Spring Hose Clamp is instrumental in maintaining the integrity and efficiency of various engine systems. In the context of a breather system, this clamp ensures a secure connection between the breather hose and the crankcase ventilation system. This connection is essential for managing pressure within the crankcase, allowing for the safe release of gases and moisture that accumulate during engine operation.

By providing a reliable seal, the Spring Hose Clamp prevents leaks that could lead to decreased engine performance and increased emissions. Additionally, in the crankcase system, the clamp helps maintain the proper flow of gases, contributing to the overall health and longevity of the engine. Its role in these systems underscores the importance of using high-quality components to ensure optimal engine function and durability.

Conclusion

The Spring Hose Clamp Part #3092253 by Cummins is a critical component in ensuring the efficient and reliable operation of commercial trucks. Its durable construction, ease of installation, and compatibility with various Cummins engines make it a valuable asset in maintaining the integrity of fluid transfer systems. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring long-term reliability and performance.

-

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩ -

Konrad Reif Ed, Gasoline Engine Management Systems and Components, Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.