3923369

Spring Hose Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Spring Hose Clamp, identified by Part #3923369, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This clamp is significant in the maintenance and operation of commercial trucks, ensuring the secure attachment of hoses within various systems. Cummins, known for its commitment to quality and innovation, provides this clamp as part of its extensive range of automotive and heavy-duty truck parts.

Basic Concepts of Spring Hose Clamps

Spring hose clamps are mechanical devices used to secure hoses to fittings in automotive and industrial applications. They consist of a band, typically made of metal or high-strength polymer, and a screw mechanism that allows for adjustable tension. The primary function of these clamps is to create a secure, leak-proof connection between hoses and their corresponding fittings, which is vital for the efficient operation of fluid systems in vehicles 1.

Purpose of the 3923369 Spring Hose Clamp in Truck Operation

The 3923369 Spring Hose Clamp plays a role in the operation of a truck by securing hoses in place, which is fundamental for maintaining the integrity of various systems such as the cooling, fuel, and hydraulic systems. By ensuring a tight and reliable connection, this clamp helps prevent leaks and maintains the efficiency of fluid transfer within the truck’s systems.

Key Features

The 3923369 Spring Hose Clamp is characterized by several key features that enhance its performance. It is constructed from durable materials, designed to withstand the rigors of commercial truck environments. The clamp features a robust screw mechanism for adjustable tension, allowing for a secure fit on a variety of hose sizes. Additionally, its design includes elements that protect the hose from damage during installation and operation.

Benefits of Using the 3923369 Spring Hose Clamp

Utilizing the 3923369 Spring Hose Clamp offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation, thanks to its adjustable screw mechanism, allows for quick and efficient hose connections. Furthermore, its reliability in various operating conditions makes it a valuable component for maintaining the performance of truck systems.

Installation and Usage Guidelines

Proper installation of the 3923369 Spring Hose Clamp involves several steps to ensure a secure and leak-proof connection. Begin by selecting the appropriate clamp size for the hose diameter. Place the clamp around the hose and fitting, ensuring it is aligned correctly. Use the screw mechanism to tighten the clamp until the hose is securely held in place without over-tightening, which could damage the hose. It is compatible with a range of hose types and sizes, making it versatile for various applications.

Maintenance and Troubleshooting

To maintain the 3923369 Spring Hose Clamp, regular inspections are recommended to check for signs of wear or damage. Common issues may include loosening of the clamp or damage to the hose, which can be addressed by re-tightening the clamp or replacing the hose as necessary. Ensuring the clamp remains in good condition will help maintain the integrity of the hose connections and the overall system performance.

Safety Considerations

When handling and installing the 3923369 Spring Hose Clamp, it is important to follow safety guidelines to protect against injury. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses. Additionally, ensure the work area is clean and free from hazards, and follow safe work practices to prevent accidents during installation and maintenance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence is evident in its products, which are trusted by professionals worldwide for their performance and durability.

Spring Hose Clamp 3923369 Compatibility with Cummins Engines

The Spring Hose Clamp 3923369, manufactured by Cummins, is a versatile component designed to fit a variety of Cummins engines. This part is essential for securing hoses and ensuring leak-proof connections in engine systems. Below is a detailed description of its compatibility with different Cummins engines:

ISB Series Engines

- ISB CM550

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

The ISB series engines, known for their reliability and performance, utilize the Spring Hose Clamp 3923369 to maintain secure hose connections. This clamp is particularly useful in high-pressure environments, ensuring that hoses remain firmly attached and do not dislodge under operational stress.

ISBE and ISC Series Engines

- ISBE CM800

- ISC CM2150

These engines benefit from the Spring Hose Clamp 3923369 by providing a reliable method to secure various hoses. The clamp’s design ensures that it can withstand the operational demands of these engines, maintaining integrity and preventing leaks.

ISF Series Engines

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

The ISF series engines, often used in applications requiring lower emissions and fuel efficiency, also incorporate the Spring Hose Clamp 3923369. This part is crucial for maintaining the efficiency and performance of these engines by ensuring that hoses are securely fastened.

ISL and ISL G Series Engines

- ISL CM2150

- ISL G CM2180

The ISL and ISL G series engines, designed for heavy-duty applications, use the Spring Hose Clamp 3923369 to secure hoses in demanding conditions. This clamp is engineered to provide a robust and reliable connection, ensuring that hoses remain in place even under extreme operational stresses.

B Series Engines

- B3.3

- B4.5

- B5.6

- B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

- B6.7 CM2670 B153B

The B series engines, known for their versatility and widespread use, also integrate the Spring Hose Clamp 3923369. This clamp is essential for maintaining the integrity of hose connections in these engines, ensuring that they operate efficiently and reliably.

G Series Engines

- G8.3

- GTA8.3 CM558

- C GAS PLUS CM556

The G series engines, designed for specific applications requiring high power and efficiency, utilize the Spring Hose Clamp 3923369 to secure hoses. This clamp ensures that hoses remain firmly attached, preventing leaks and maintaining the operational integrity of these engines.

F Series Engines

- F2.8 CM2620 F135B

The F series engines, often used in specialized applications, also incorporate the Spring Hose Clamp 3923369. This part is crucial for maintaining the efficiency and performance of these engines by ensuring that hoses are securely fastened.

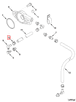

Role of Part 3923369 Spring Hose Clamp in Engine Systems

The part 3923369 Spring Hose Clamp is an essential component in various engine systems, ensuring secure and reliable connections across multiple applications.

In the accessories section, this clamp is utilized to maintain the integrity of connections in the fuel system. It ensures that the fuel lines are tightly secured, preventing leaks and maintaining consistent fuel pressure.

Within the air compressor kit, the clamp plays a significant role in the arrangement of the compressor air inlet and compressor coolant. It secures the hoses that carry compressed air and coolant, ensuring efficient operation and preventing any potential leaks that could affect performance.

In the oil fill and breather systems, the clamp is employed to connect the crankcase breather tube. This connection is vital for maintaining proper ventilation of the crankcase, which is essential for the overall health of the engine.

For the compressor, whether it involves air or fuel, the clamp is used to secure the connections to the lift pump and fuel control module. This ensures that the fuel delivery system operates smoothly without interruptions.

The molded hose and molded hose kit sections benefit from the clamp by providing a secure fit for various plumbing applications. This includes the cabin heater plumbing, compressor coolant plumbing, and crankcase breather plumbing. Each of these applications requires a reliable connection to function correctly.

In the exhaust recirculation water and turbocharger plumbing systems, the clamp ensures that the connections remain intact under high pressure and temperature conditions. This is particularly important for the turbocharger oil drain connection and the overall turbocharger plumbing, where any leak could lead to significant performance issues.

Additionally, the clamp is used in the pump and fuel transfer systems to secure hoses that carry fuel and other fluids. It also plays a role in the exhaust recirculation system, helping to maintain the efficiency of the exhaust system by securing the necessary connections.

Overall, the part 3923369 Spring Hose Clamp is a versatile component that enhances the reliability and efficiency of various engine systems by providing secure and leak-proof connections.

Conclusion

The 3923369 Spring Hose Clamp is a critical component for maintaining the operational integrity of various Cummins engines. Its design ensures that hoses remain securely fastened, preventing leaks and ensuring that the engines operate efficiently and reliably. The clamp’s durable construction, ease of installation, and compatibility with a wide range of Cummins engines make it an invaluable part for professionals in the commercial truck industry.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.