This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4900712 Hydraulic Pump Gear, manufactured by Cummins, is a component designed for use in commercial trucks. It is integral to the hydraulic systems that are prevalent in heavy-duty vehicles. Hydraulic systems in trucks are responsible for various functions, including braking, steering, and lifting. This Cummins part contributes to the efficiency and reliability of these systems, ensuring that trucks operate smoothly and effectively.

Basic Concepts of Hydraulic Pump Gears

Hydraulic systems operate on the principle of fluid power, where hydraulic fluid is used to transmit force 1. Within these systems, hydraulic pump gears play a significant role. They function by converting mechanical energy into hydraulic energy, generating the pressure needed to move hydraulic fluids through the system. This movement facilitates the operation of various truck components, enabling precise and powerful control over vehicle functions.

Purpose of the 4900712 Hydraulic Pump Gear

The 4900712 Hydraulic Pump Gear is specifically designed to enhance the operation of a truck’s hydraulic system. It contributes to several truck functions, including braking, steering, and lifting mechanisms. By ensuring a consistent and reliable flow of hydraulic fluid, this gear helps maintain the performance and safety of these critical systems.

Key Features

The 4900712 Hydraulic Pump Gear is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and resistance to wear. The gear tooth profile is meticulously designed to optimize fluid flow and minimize noise during operation. Additionally, unique design elements enhance its performance and longevity, making it a reliable component for heavy-duty applications.

Benefits

The 4900712 Hydraulic Pump Gear offers several advantages, including improved efficiency, reliability, and longevity. These benefits contribute to better overall truck performance and can lead to operational cost savings. The gear’s design ensures that it operates smoothly under demanding conditions, reducing the likelihood of downtime and maintenance issues.

Installation and Integration

Proper installation of the 4900712 Hydraulic Pump Gear is vital for its effective operation within a truck’s hydraulic system. It is important to ensure compatibility with other system components and to follow manufacturer guidelines during installation. Taking necessary precautions, such as checking for proper alignment and secure fastening, will help maintain the integrity of the hydraulic system.

Troubleshooting Common Issues

Common problems associated with hydraulic pump gears can include leaks, unusual noises, and decreased performance. Identifying these issues early is important for maintaining system efficiency. Troubleshooting procedures may involve inspecting for worn components, checking fluid levels, and ensuring that all connections are secure. Addressing these issues promptly can prevent more significant problems down the line.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the 4900712 Hydraulic Pump Gear. This includes routine fluid changes to keep the hydraulic system clean and functioning efficiently. Inspections should be conducted to check for signs of wear or damage, and timely replacements of worn components are recommended to prevent system failures.

Cummins: A Brief Overview

Cummins Inc. is a well-established name in the commercial vehicle industry, known for its commitment to innovation and quality. With a rich history of providing reliable power solutions, Cummins offers a wide range of products designed to meet the demanding needs of commercial trucks. Their reputation for excellence is built on a foundation of continuous improvement and customer satisfaction 2.

Hydraulic Pump Gear 4900712 Compatibility with Cummins Engines

The Hydraulic Pump Gear 4900712, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines. This part is crucial for the proper functioning of the hydraulic systems in these engines, ensuring efficient power transfer and optimal performance.

A1400 and A1700 Engines

The Hydraulic Pump Gear 4900712 is compatible with both the A1400 and A1700 engines. These engines are known for their reliability and efficiency, often used in various industrial and commercial applications. The gear’s design ensures that it fits perfectly within the hydraulic system architecture of these engines, facilitating smooth operation and reducing the likelihood of mechanical failures.

A2000 and A2300 Engines

Similarly, the Hydraulic Pump Gear 4900712 is also suitable for the A2000 and A2300 engines. These engines are typically employed in heavy-duty applications where robust performance and durability are paramount. The gear’s precision engineering guarantees that it will work in harmony with the hydraulic systems of these engines, enhancing overall efficiency and longevity.

Grouping for Efficiency

When considering the compatibility of the Hydraulic Pump Gear 4900712 with the A1400, A1700, A2000, and A2300 engines, it is evident that the gear is designed to fit within the broader family of Cummins engines. This grouping ensures that the gear can be used across multiple engine models, simplifying maintenance and repair processes. Technicians and engineers can rely on this part to provide consistent performance across different engine types, making it a versatile and valuable component in the Cummins engine ecosystem.

Role of Part 4900712 Hydraulic Pump Gear in Engine Systems

The hydraulic pump gear, specifically part 4900712, is an integral component in the efficient operation of engine systems. Its primary function is to ensure the smooth and consistent flow of hydraulic fluid, which is essential for the operation of various engine mechanisms.

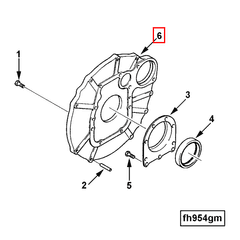

Interaction with Housing

The hydraulic pump gear is housed within the engine’s housing, a protective enclosure that safeguards the internal components from external contaminants and damage. The gear’s precise fit within the housing ensures minimal friction and maximum efficiency. The housing also plays a role in maintaining the optimal temperature and pressure conditions necessary for the hydraulic fluid to perform effectively. The gear’s interaction with the housing is designed to facilitate easy maintenance and replacement, ensuring that the engine system remains reliable and durable over time.

Coordination with Flywheel

The hydraulic pump gear works in tandem with the flywheel, a rotating mechanical device that stores rotational energy. The gear’s consistent rotation is essential for the flywheel to maintain its momentum, which in turn ensures a stable power supply to the engine. This coordination is vital for the engine’s smooth operation, especially during periods of high demand or variable load conditions. The gear’s design allows it to mesh perfectly with the flywheel, ensuring that energy transfer is efficient and uninterrupted.

Conclusion

The 4900712 Hydraulic Pump Gear is a critical component in the hydraulic systems of commercial trucks, ensuring efficient and reliable operation of various truck functions. Its robust design, compatibility with Cummins engines, and integration with engine systems highlight its importance in maintaining the performance and safety of heavy-duty vehicles. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.