This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

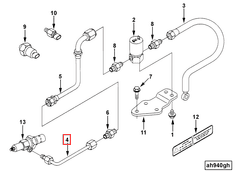

The Cummins part 3926039, known as the Starting Aid Tube, is a component designed to enhance the start-up process of heavy-duty engines. This part facilitates easier engine start-up, particularly under challenging conditions such as low temperatures or when the engine is cold. The Starting Aid Tube provides a pathway for pressurized air or fluid to assist in the initial cranking phase, thereby reducing the strain on the starter motor and battery 1.

Function and Operation

The Starting Aid Tube operates by channeling pressurized air or fluid into the engine’s combustion chambers. This action helps to create a more favorable environment for ignition, ensuring a smoother and more efficient start. Under various conditions, such as cold weather or after the engine has been idle for an extended period, the Starting Aid Tube ensures that the engine starts more reliably and with less effort 2.

Key Features

This Cummins part is constructed from durable materials that can withstand the high pressures and temperatures encountered in heavy-duty truck engines. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Unique attributes of this tube include its robust construction and the integration of features that enhance its performance and longevity in demanding environments 3.

Benefits

The incorporation of the Starting Aid Tube into a truck’s engine system offers several benefits. It contributes to improved engine start-up reliability, which is particularly advantageous in cold weather conditions. Additionally, by reducing the strain on the starter motor, it helps to extend the lifespan of this component. The tube also enhances overall engine performance by ensuring more consistent and efficient start-ups.

Installation and Integration

Proper installation of the Starting Aid Tube is crucial for its effective operation. This process involves securing the tube within the engine system, ensuring all connections are tight and free from leaks. Preparatory steps may include cleaning the installation area and verifying that all components are compatible with the truck’s engine system. Careful attention to these details ensures the tube functions as intended.

Maintenance and Troubleshooting

To maintain optimal performance, regular inspection of the Starting Aid Tube is recommended. This includes checking for signs of wear, corrosion, or leaks. Should any issues arise, such as difficulty starting the engine or unusual noises during start-up, these may indicate a problem with the tube. Troubleshooting steps can include verifying connections, checking for obstructions, and ensuring the tube is free from damage.

Safety Considerations

When working with the Starting Aid Tube, it is important to follow safety precautions. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, ensuring the engine is off and cool before beginning any work on the tube helps to prevent accidents. Awareness of the pressurized air or fluid within the system is also crucial to avoid injury.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation within the automotive and heavy-duty truck industries. Its product offerings include a wide range of engines and components designed to meet the demanding requirements of commercial and industrial applications.

Conclusion

The Cummins part 3926039 Starting Aid Tube is a vital component in enhancing the start-up process of heavy-duty engines. By facilitating a smoother and more efficient start, it reduces the strain on engine components, leading to improved efficiency and reduced emissions. Its robust construction and precise design ensure durability and reliability in demanding environments, making it an essential part of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.