This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3926626 Starting Aid Tube is a component designed to facilitate the starting process of diesel engines in heavy-duty trucks. Its role is significant as it ensures reliable engine starts under various conditions, contributing to the overall efficiency and performance of the vehicle 1.

Purpose and Function

The Starting Aid Tube plays a role in the starting process of diesel engines by providing an additional source of fuel or air to aid in the initial cranking of the engine. This is particularly useful in cold weather conditions where diesel fuel can become more viscous, making it harder for the engine to start. By delivering a measured amount of fuel or air, the Starting Aid Tube helps to ensure that the engine starts smoothly and efficiently 2.

Key Features

The design and construction of the Starting Aid Tube incorporate materials that are resistant to the harsh conditions within a diesel engine. Typically, it is made from durable metals or high-strength polymers that can withstand high temperatures and pressures. Its unique characteristics include a precise delivery system that ensures the correct amount of fuel or air is provided during the starting process, enhancing its performance and reliability.

Operational Benefits

The advantages provided by the Starting Aid Tube include improved starting reliability in cold weather, which is a common challenge for diesel engines. It also reduces the strain on the starter motor by facilitating easier engine cranking. Additionally, the Starting Aid Tube contributes to enhanced overall engine performance by ensuring that the engine starts quickly and runs smoothly from the outset.

Installation and Compatibility

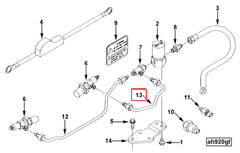

Proper installation of the Starting Aid Tube is crucial for its effective operation. It is designed to integrate seamlessly with specific engine models, ensuring that it functions as intended within the engine system. Specific requirements for integration may include precise alignment and secure fastening to prevent leaks or malfunctions.

Maintenance and Troubleshooting

Regular maintenance practices for the Starting Aid Tube include checking for leaks, ensuring all connections are secure, and verifying that the delivery system is functioning correctly. Common issues that may arise include blockages or wear on the tube, which can be addressed by cleaning or replacing the affected parts. Troubleshooting steps may involve inspecting the tube for damage, ensuring the delivery system is calibrated correctly, and verifying that all connections are intact.

Safety Considerations

When working with the Starting Aid Tube, it is important to observe safety precautions to prevent accidents or injuries. Potential hazards include high-pressure fuel or air, which can cause harm if mishandled. To mitigate these risks, it is advisable to follow proper handling procedures, use appropriate personal protective equipment, and ensure that the engine is turned off and cooled down before performing any maintenance or repairs.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency.

Cummins Engine Part 3926626: Starting Aid Tube

The Cummins part 3926626, known as the Starting Aid Tube, is a critical component in the starting system of certain Cummins engines. This part is designed to facilitate the starting process by providing a pathway for compressed air or other starting aids to reach the engine’s cylinders.

Application in Cummins Engines

The Starting Aid Tube is compatible with several Cummins engine models, including but not limited to:

- 6C8.3: This engine model benefits from the Starting Aid Tube by ensuring a smoother and more efficient starting process. The tube’s role in delivering compressed air to the cylinders helps overcome the high compression ratios that can make starting these engines challenging.

Importance of the Starting Aid Tube

The Starting Aid Tube is essential for the following reasons:

- Enhanced Starting Efficiency: By providing a direct pathway for compressed air, the tube ensures that the engine receives the necessary boost to start, especially in cold or high-stress conditions.

- Reduced Wear and Tear: The use of a starting aid tube can help reduce the strain on the engine’s components, leading to a longer service life.

- Improved Reliability: Ensuring that the engine starts reliably is crucial for the overall performance and longevity of the engine.

Installation and Maintenance

Proper installation and maintenance of the Starting Aid Tube are crucial to ensure its effectiveness. Regular inspections should be conducted to check for any leaks, blockages, or damage that could affect its performance. Cummins recommends following the manufacturer’s guidelines for maintenance intervals and procedures to keep the starting aid system in optimal condition.

Role of Part 3926626 Starting Aid Tube in Engine Systems

The Part 3926626 Starting Aid Tube is an essential component in the efficient operation of several engine systems, particularly in cold-weather starting scenarios. This component is integral to the functionality of the Starting Aid Kit, which is designed to facilitate easier engine starts under adverse conditions.

Integration with Air Heater Starting System

In the Air Heater Starting system, the Starting Aid Tube plays a significant role by directing heated air into the engine’s intake tract. This preheated air reduces the viscosity of the engine oil and lowers the density of the air-fuel mixture, making it easier for the engine to start. The tube ensures that the heated air is delivered efficiently to the combustion chambers, enhancing the overall starting performance of the engine.

Function in Air Intake Heater System

When integrated with the Air Intake Heater system, the Starting Aid Tube contributes to the warming of the incoming air before it enters the engine. This is particularly beneficial in cold climates where the air is dense and can be difficult for the engine to compress effectively. By preheating the air, the tube helps in achieving a more optimal air-fuel ratio, which is essential for smooth and reliable engine starts.

Contribution to Starting Aid Kit

As part of the Starting Aid Kit, the Starting Aid Tube is responsible for channeling the heated air from the heater unit to the engine’s air intake system. This kit is often used in diesel engines, where cold starts can be particularly challenging due to the high compression ratios and the need for precise fuel injection timing. The tube ensures that the heated air is consistently supplied to the engine, reducing start-up times and minimizing the wear and tear on the engine components during cold starts.

Conclusion

In summary, the Part 3926626 Starting Aid Tube is a vital component that enhances the performance and reliability of engine systems by ensuring that preheated air is effectively delivered to the engine’s intake tract. This not only improves starting efficiency but also contributes to the overall longevity and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.