This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3976571 Emergency Stop Contact Block is a critical component in the safety systems of commercial trucks. It is designed to facilitate the immediate shutdown of a truck’s electrical systems in emergency scenarios, ensuring the safety of the operator and bystanders 1.

Basic Concepts of Emergency Stop Contact Blocks

An Emergency Stop Contact Block is a safety device used in the electrical systems of various machinery, including commercial trucks. Its primary function is to interrupt the power supply to the machinery’s components when an emergency stop is activated. This action is essential for preventing accidents and ensuring safety 2.

Purpose of the Cummins 3976571 Emergency Stop Contact Block

This Cummins part is specifically designed to enable the immediate shutdown of a truck’s electrical systems in emergency situations. By interrupting the power supply, it prevents further operation of the truck, which is vital in scenarios where continuing operation could lead to accidents or damage 1.

Key Features

The Cummins 3976571 Emergency Stop Contact Block is known for its robust design and high-quality materials, which contribute to its durability and reliability. It is engineered to withstand the demanding conditions of commercial truck operations, ensuring consistent performance over time. The block features multiple contact points for controlling different circuits, allowing for precise and effective shutdown procedures. Its design also includes protective measures to guard against environmental factors, such as moisture and dust, which could otherwise impair its function 2.

Benefits

Utilizing the Cummins 3976571 Emergency Stop Contact Block offers several advantages. It enhances the safety of truck operations by providing a reliable means to halt the truck in emergencies. Additionally, its robust construction and design contribute to the overall reliability and efficiency of the truck’s electrical system. The block’s ability to precisely control the shutdown of various circuits ensures that the truck can be stopped safely without causing damage to its electrical components 1.

Installation and Integration

Proper installation and integration of the Cummins 3976571 Emergency Stop Contact Block within a truck’s electrical system are crucial for ensuring its effective operation. Installation should be performed by qualified professionals to ensure that all connections are secure and that the block is correctly positioned within the system. It is important to follow the manufacturer’s guidelines for installation to avoid any issues that could compromise the block’s function or the safety of the truck’s operation 2.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for ensuring the optimal performance and longevity of the Cummins 3976571 Emergency Stop Contact Block. Inspections should be conducted periodically to check for signs of wear or damage, and any issues should be addressed promptly to prevent them from escalating. Maintenance practices may include cleaning the block to remove any dirt or debris that could affect its operation, as well as checking the integrity of its connections and contacts 1.

Safety Considerations

When working with the Cummins 3976571 Emergency Stop Contact Block, it is important to adhere to safety considerations and best practices. This includes ensuring that the block is handled and installed by qualified personnel to avoid any risks associated with improper use. Additionally, understanding the emergency procedures related to the block’s operation is crucial for ensuring that it can be effectively utilized in emergency situations. Proper training and awareness of safety protocols are essential for maintaining a safe working environment 2.

Regulatory Compliance

The use of emergency stop systems in commercial trucks is subject to various regulatory standards and compliance requirements. These regulations are designed to ensure that trucks are equipped with effective safety systems that can protect operators and bystanders in emergency situations. It is important for truck operators and maintenance personnel to be aware of these regulations and to ensure that the Cummins 3976571 Emergency Stop Contact Block is installed and maintained in compliance with all relevant industry standards and guidelines 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the industry, Cummins is committed to providing high-quality components that meet the demanding needs of commercial truck operators. The company’s dedication to quality and innovation is reflected in its wide range of products, including the Cummins 3976571 Emergency Stop Contact Block, which is designed to enhance the safety and reliability of commercial trucks 2.

Compatibility

The Cummins Emergency Stop Contact Block, identified by part number 3976571, is engineered to work seamlessly with various Cummins engine models, ensuring that safety protocols are upheld across different engine types.

Engine Compatibility

- 6B5.9 and 6C8.3 Engines

The Emergency Stop Contact Block is compatible with the 6B5.9 and 6C8.3 engines. These engines are known for their robust performance and reliability, often utilized in heavy-duty applications. The integration of the 3976571 part ensures that these engines can be safely and effectively managed, providing an additional layer of safety for operators and maintenance personnel.

- Other Cummins Engines

While the primary focus here is on the 6B5.9 and 6C8.3 engines, it is important to note that the 3976571 Emergency Stop Contact Block is also compatible with a range of other Cummins engines. This broad compatibility underscores the versatility and importance of the part in ensuring engine safety across various applications.

The design and functionality of the Emergency Stop Contact Block are tailored to meet the stringent safety requirements of Cummins engines. Its installation and operation are straightforward, ensuring that it can be effectively utilized in both routine maintenance and emergency scenarios 2.

Role in Engine Systems

The 3976571 Emergency Stop Contact Block is an integral component in the safe operation of various engine systems. It is designed to provide a rapid shutdown mechanism in emergency situations, ensuring the safety of personnel and equipment.

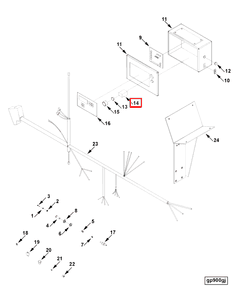

Integration with Control Panel

When integrated into the control panel, the Emergency Stop Contact Block serves as a fail-safe mechanism. Upon activation, it interrupts the electrical circuit, leading to an immediate halt of engine operations. This is particularly important in scenarios where manual intervention is required to prevent potential hazards 1.

Functionality in Engine Instrument Systems

In engine instrument systems, the 3976571 component works in conjunction with sensors and monitoring devices. It ensures that any abnormal readings or malfunctions can trigger an emergency shutdown. This proactive approach helps in minimizing damage and reducing the risk of catastrophic failures 2.

Role in Panel Systems

Within panel systems, the Emergency Stop Contact Block is often connected to multiple subsystems. Its role is to provide a unified shutdown command that can be executed from a centralized location. This is especially beneficial in complex engine setups where multiple components need to be halted simultaneously 1.

Coordination with Engine Instruments

The Emergency Stop Contact Block coordinates with engine instruments to monitor real-time data. If any parameter exceeds safe limits, the block can be triggered automatically, ensuring that the engine stops before any damage occurs. This seamless integration enhances the overall reliability and safety of the engine system 2.

Conclusion

The Cummins 3976571 Emergency Stop Contact Block plays a vital role in the safety and operational integrity of commercial trucks. Its robust design, compatibility with various Cummins engines, and integration within engine systems ensure that it can effectively manage emergency situations, providing a reliable means to halt the truck’s operations and protect both the operator and bystanders.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.