This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

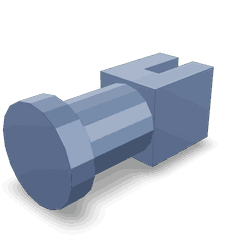

The Cummins 4963996 Emergency Stop Switch is designed to enhance safety and operational control in commercial trucks. It provides a rapid means of shutting down the truck’s engine and other critical systems during emergencies, helping to prevent accidents and mitigate potential damage.

Basic Concepts of Emergency Stop Switches

An Emergency Stop Switch (E-stop) is a safety device used to quickly shut off machinery in emergencies where normal shutdown procedures may not be fast enough. In commercial trucks, the E-stop switch is integrated into the vehicle’s electrical system to allow immediate cessation of operations, which can be vital in preventing collisions, equipment damage, or injuries 1.

Purpose of the Cummins 4963996 Emergency Stop Switch

This Cummins part provides a quick and efficient method to deactivate the engine and other systems when an emergency arises. Upon activation, the switch interrupts the power supply to the engine and other electrical components, bringing the truck to a safe stop 2.

Key Features

The Cummins 4963996 Emergency Stop Switch is characterized by its robust design and high-quality materials to ensure durability and reliability. It features a straightforward activation mechanism, typically a large, easily accessible button. The switch is designed to withstand harsh conditions encountered in commercial trucking, including vibrations, temperature extremes, and exposure to the elements 3.

Benefits of Using the Cummins 4963996 Emergency Stop Switch

Incorporating this part into a truck’s system offers several advantages. It enhances safety by providing a quick means to stop the vehicle in emergencies, potentially preventing accidents. It also contributes to operational efficiency by allowing a rapid response to unexpected situations. The reliability of the switch ensures it functions correctly when needed, offering peace of mind to drivers and operators 4.

Installation and Integration

Proper installation and integration of the Cummins 4963996 Emergency Stop Switch within a truck’s electrical system are vital for ensuring compatibility and optimal performance. It should be installed in an easily accessible location for quick activation in an emergency. Integration into the truck’s electrical system requires careful consideration of the vehicle’s wiring and electrical components to ensure the switch can effectively interrupt power to the necessary systems 5.

Troubleshooting Common Issues

Common issues with the Cummins 4963996 Emergency Stop Switch may include failure to activate, intermittent operation, or complete malfunction. Troubleshooting steps can involve checking the electrical connections for corrosion or damage, ensuring the switch is correctly installed, and testing the switch’s functionality. If the switch does not operate as expected, it may require adjustment, repair, or replacement 6.

Maintenance Tips

Regular maintenance of the Cummins 4963996 Emergency Stop Switch is important to ensure it remains in good working condition. This includes periodic inspection for signs of wear or damage, cleaning the switch and its surrounding area to prevent debris accumulation, and testing the switch’s operation to confirm it functions correctly. Adhering to a maintenance schedule helps to identify potential issues before they lead to failure in an emergency 7.

Safety Protocols

When dealing with the Cummins 4963996 Emergency Stop Switch, it is important to follow safety protocols to prevent accidents. This includes proper handling during installation and maintenance, ensuring the switch is only activated in genuine emergencies, and training personnel on the correct use of the switch. Emphasizing the importance of these protocols helps to maintain a safe working environment 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries, continually advancing the technology that powers the world 9.

Compatibility with Cummins Engines

The Emergency Stop Switch 4963996 is designed to provide a critical safety feature across a range of Cummins engines. This switch is engineered to immediately halt engine operation in emergency situations, ensuring the safety of both the machinery and the operators.

Compatibility with K-Series Engines

The K19, K38, and K50 engines are part of Cummins’ K-Series line, known for their robust performance and reliability in various industrial applications. The Emergency Stop Switch 4963996 is compatible with these engines, providing a standardized safety mechanism across the series.

Compatibility with QSK Engines

The QSK19 CM850 MCRS, QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK60 CM850 MCRS engines represent Cummins’ QSK-Series, which is designed for demanding applications requiring high power and efficiency. The Emergency Stop Switch 4963996 fits seamlessly into these engines, ensuring that the emergency stop functionality is consistent across the series.

Compatibility with QSM Engines

The QSM11 CM570 engine, part of Cummins’ QSM-Series, is designed for medium-duty applications. This engine benefits from the Emergency Stop Switch 4963996, which integrates smoothly into the engine’s control systems, providing an essential safety feature for operators in various environments.

Grouping by Application

The Emergency Stop Switch 4963996 is strategically designed to fit across different engine series, ensuring that safety protocols are uniformly applied. Whether in the K-Series, QSK-Series, or QSM-Series, this switch is a critical component that enhances the overall safety of the machinery.

Integration of Part 4963996 Emergency Stop Switch in Engine Systems

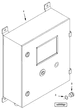

The part 4963996 Emergency Stop Switch is an essential component in the safe operation of various engine systems. It is strategically integrated into the control panel, where it serves as a rapid response mechanism to halt engine operations in emergency scenarios.

When installed in the junction box panel, the Emergency Stop Switch ensures immediate power cutoff to the engine, safeguarding both the machinery and the operator. Its placement within the package is designed for easy access, allowing for swift action when needed.

During product installation, careful consideration is given to the positioning of the Emergency Stop Switch to ensure it is within immediate reach of the operator. This is vital for quick response times in emergency situations.

On the panel, the switch is often accompanied by clear labeling and, in some cases, visual indicators to confirm its activation status. This integration enhances the overall safety protocol of the engine instrument system.

Within the engine monitoring system, the Emergency Stop Switch is linked to various sensors and monitoring units. This connection allows for an automated response to certain emergency conditions detected by the system, further enhancing safety measures.

The role of the Emergency Stop Switch in these components underscores its importance in maintaining a secure operating environment for engine systems. Its integration is a testament to the commitment to safety in engine design and operation.

Conclusion

The Cummins 4963996 Emergency Stop Switch is a vital component for enhancing safety and operational control in commercial trucks. Its robust design, ease of use, and compatibility with various Cummins engines make it an essential part of any truck’s safety system. Regular maintenance and adherence to safety protocols ensure that this part remains effective in emergency situations, contributing to the overall safety and efficiency of commercial truck operations.

-

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021619, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021619, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021619, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021619, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021619, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). General Information. Bulletin Number 4021619, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.