This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5282922 Emergency Stop Switch is a critical component designed for use in commercial trucks. Its primary function is to provide a quick and efficient means to halt the vehicle’s operation in emergency situations, enhancing safety and operational control. This switch is integral to the truck’s safety system, ensuring that drivers can respond promptly to unforeseen circumstances.

Purpose and Functionality

The Emergency Stop Switch serves a vital function in a truck’s operation by allowing the driver to immediately stop the vehicle in case of an emergency. When activated, it cuts off power to the engine and other critical systems, bringing the truck to a halt. This feature is particularly important in scenarios where immediate cessation of movement is necessary to prevent accidents or further damage 1.

Key Features

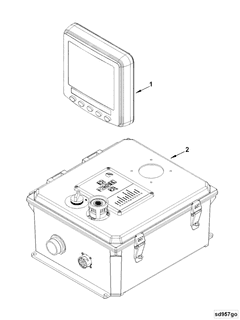

The Cummins 5282922 Emergency Stop Switch is characterized by its robust design and high-quality materials. It is constructed to withstand the rigors of commercial truck environments, ensuring durability and reliability. The switch is designed for easy access and activation, with a prominent placement that allows for quick use in emergencies. Additionally, it incorporates safety mechanisms to prevent accidental activation, ensuring that it is only used when necessary 2.

Benefits of Using the Cummins 5282922 Emergency Stop Switch

Utilizing the Cummins 5282922 Emergency Stop Switch offers several advantages. It enhances safety by providing a reliable means to stop the truck quickly in emergencies. The switch is designed for ease of use, ensuring that drivers can activate it without hesitation. Its reliability in critical situations makes it a valuable component for any commercial truck, contributing to overall operational safety 3.

Installation and Integration

Proper installation of the Cummins 5282922 Emergency Stop Switch is essential for its effective operation. It should be integrated into the truck’s electrical system according to the manufacturer’s guidelines. This process may involve connecting the switch to the engine control unit and ensuring that it is properly grounded. Careful attention to these details during installation will ensure that the switch functions correctly when needed 4.

Troubleshooting Common Issues

Common issues with the Emergency Stop Switch may include failure to activate or accidental activation. Troubleshooting steps may involve checking the electrical connections, ensuring that the switch is properly grounded, and inspecting for any physical damage. Regular testing of the switch can help identify potential issues before they become critical 5.

Maintenance and Care

Routine maintenance of the Cummins 5282922 Emergency Stop Switch is important to ensure its longevity and optimal performance. This may include periodic inspection of the switch for signs of wear or damage, cleaning the contacts to prevent corrosion, and testing the switch to ensure it activates correctly. Regular maintenance will help maintain the switch’s reliability in emergency situations 6.

Safety Protocols

When using the Cummins 5282922 Emergency Stop Switch, it is important to follow safety protocols and best practices. This includes training operators on the proper use of the switch and conducting regular safety checks to ensure it is functioning correctly. Operators should be aware of the switch’s location and how to activate it in an emergency 7.

Regulatory Compliance

The Cummins 5282922 Emergency Stop Switch meets industry standards and regulatory requirements for commercial vehicle safety. It is designed to comply with relevant safety regulations, ensuring that it provides a reliable means of stopping the vehicle in emergencies. This compliance helps ensure the safety of the vehicle’s occupants and other road users 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to excellence is evident in its products, including the Cummins 5282922 Emergency Stop Switch, which is designed to meet the high standards of commercial vehicle safety and reliability 9.

Compatibility

The Cummins Emergency Stop Switch part number 5282922 is designed to provide a critical safety feature across a range of engine models. This switch is engineered to immediately halt engine operation in emergency situations, ensuring the safety of both the machinery and personnel.

QSM11 Engines

For the QSM11 series, the Emergency Stop Switch part 5282922 is a vital component that integrates seamlessly into the engine’s control system. Its placement and functionality are standardized across various QSM11 engine configurations, ensuring consistent performance and reliability.

CM570 Engines

Similarly, in the CM570 engine series, the Emergency Stop Switch part 5282922 is meticulously designed to fit into the engine’s architecture. This switch is strategically positioned to be easily accessible during an emergency, providing a quick and reliable means to stop the engine.

Grouping of Engines

The Emergency Stop Switch part 5282922 is compatible with both the QSM11 and CM570 engines, making it a versatile component for various industrial applications. Its design ensures that it can be integrated into different engine models without requiring significant modifications, thereby maintaining the integrity of the engine’s safety protocols.

Role in Engine Systems

The Part 5282922 Emergency Stop Switch is an integral component in the orchestration of various engine systems, ensuring safety and operational integrity. When integrated into the control panel, this switch provides a rapid means to halt engine operations in emergency scenarios, safeguarding both the machinery and the operator.

During product installation, the switch is strategically placed within the panel to offer immediate access. This placement is vital for quick response times during unforeseen events. The switch interacts seamlessly with the engine instrument systems, allowing for instantaneous communication between the operator and the engine’s operational status.

In the context of engine monitoring systems, the Emergency Stop Switch serves as a fail-safe mechanism. It ensures that any detected anomalies or dangerous conditions can be addressed promptly by stopping the engine. This interaction is essential for maintaining the engine’s health and prolonging its operational life.

Furthermore, the switch’s role extends to the engine system as a whole, where it acts as a protective barrier against potential damage from over-revving, mechanical failures, or other hazardous conditions. Its integration into the system design underscores the importance of having a reliable method to cease engine function when necessary.

Conclusion

In summary, the Part 5282922 Emergency Stop Switch is a key component in the safety architecture of engine systems, providing a vital link between the operator, the control mechanisms, and the engine itself. Its proper installation and integration are essential for the effective management of engine operations and the assurance of safety across various applications.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Cummins Inc. Service Manual (5659998). B4.5 CM2350 B160M.

↩ -

Cummins Inc. Service Manual (5659998). B4.5 CM2350 B160M.

↩ -

Cummins Inc. Service Manual (5659998). B4.5 CM2350 B160M.

↩ -

Cummins Inc. Service Manual (5659998). B4.5 CM2350 B160M.

↩ -

Cummins Inc. Service Manual (5659998). B4.5 CM2350 B160M.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.