3823348

Top Stop Tappet Lift Tool

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

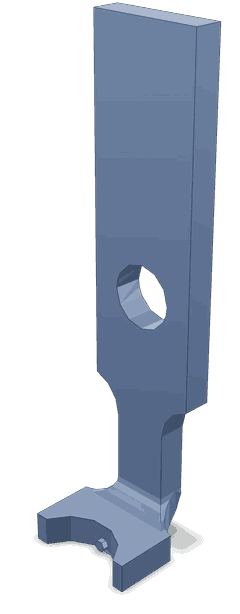

The Top Stop Tappet Lift Tool (Part #3823348) by Cummins is a specialized instrument designed for the maintenance and operation of heavy-duty trucks. Cummins, a renowned manufacturer in the automotive industry, produces this tool to facilitate the intricate processes involved in engine maintenance. This tool is integral to the upkeep of the valve train mechanism, ensuring the smooth and efficient operation of heavy-duty truck engines 1.

Basic Concepts

Tappet lift tools are fundamental in the maintenance of an engine’s valve train mechanism. Tappets, also known as lifters, play a role in transferring motion from the camshaft to the valves, ensuring they open and close at the correct times. The maintenance of tappets is crucial for the engine’s performance, and tools like the Top Stop Tappet Lift Tool are necessary for their proper servicing. These tools enable mechanics to lift and hold tappets in place, facilitating various maintenance procedures 2.

Functionality of the Top Stop Tappet Lift Tool

The Top Stop Tappet Lift Tool operates through a precise design that allows it to engage with the tappets within an engine. Its mechanism is engineered to lift and securely hold tappets during maintenance, providing mechanics with the stability needed to perform tasks such as valve adjustments or replacements. The tool’s design ensures that it can be easily inserted into the engine’s tappet bores, where it then expands to grip the tappet, keeping it in an elevated position 3.

Role in Truck Operation

In the context of truck engine maintenance, the Top Stop Tappet Lift Tool aids in ensuring the proper function and longevity of the engine’s valve train components. By facilitating the secure lifting of tappets, it allows for precise adjustments and replacements, which are vital for maintaining the engine’s efficiency and performance. This tool is particularly valuable in heavy-duty trucks, where engine reliability and performance are paramount 4.

Key Features

The Top Stop Tappet Lift Tool is characterized by its robust design and the quality of materials used in its construction. It is built to withstand the rigors of heavy-duty engine maintenance, ensuring durability and reliability. The tool’s design includes features that enhance its effectiveness, such as a mechanism that allows for precise control over the tappet’s position and a construction that resists wear and corrosion.

Benefits

Utilizing the Top Stop Tappet Lift Tool offers several advantages. It improves the efficiency of maintenance tasks by providing a secure and stable platform for tappet manipulation. This can lead to enhanced safety for mechanics, reducing the risk of injury during engine maintenance. Additionally, by facilitating more accurate and efficient maintenance, the tool can contribute to potential cost savings for fleet operators through extended engine life and reduced downtime.

Troubleshooting and Maintenance

Common issues with the Top Stop Tappet Lift Tool may include wear on the gripping mechanism or difficulties in insertion due to engine debris. Regular maintenance, such as cleaning and inspecting the tool for signs of wear, can help ensure its longevity and effectiveness. Troubleshooting may involve checking for proper insertion technique or adjusting the tool’s components to maintain its grip strength.

About Cummins

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and excellence. The company’s expertise extends to providing high-quality automotive components, including tools and parts for engine maintenance. Cummins’ commitment to innovation and quality is evident in its product line, which is designed to meet the demanding requirements of the automotive industry.

Compatibility of Cummins Part 3823348

The Cummins part 3823348, a Top Stop Tappet Lift Tool, is specifically designed to fit certain Cummins engine models. This tool is essential for maintenance and repair tasks, particularly those involving the tappet lift mechanism in the engines.

K19 and K38 Engines

The part 3823348 is compatible with the K19 and K38 engines. These engines are part of the Cummins engine family that are known for their durability and reliability in various industrial applications. The tool is designed to ensure precise adjustments and maintenance of the tappet lift, which is crucial for the smooth operation of these engines.

K50 Engine

Similarly, the Cummins part 3823348 is also suitable for the K50 engine. This engine, like the K19 and K38, benefits from the precise adjustments that the Top Stop Tappet Lift Tool provides. The compatibility of this tool with the K50 engine ensures that maintenance tasks can be performed efficiently and accurately.

Key Considerations

When using the Cummins part 3823348 on any of these engines, it is important to follow the manufacturer’s guidelines to ensure proper installation and use. This tool is designed to fit snugly and function effectively within the specified engine models, providing the necessary support for maintenance tasks.

Role of Part 3823348 Top Stop Tappet Lift Tool in Engine Systems

The Part 3823348 Top Stop Tappet Lift Tool is an essential component in the maintenance and performance optimization of engine systems. This tool is specifically designed to interact with various engine components to ensure precise adjustments and efficient operation.

Interaction with Injector Adjusting Tool

When used in conjunction with the Injector Adjusting Tool, the Top Stop Tappet Lift Tool facilitates the accurate positioning and adjustment of fuel injectors. This ensures that the fuel delivery system operates within specified parameters, enhancing engine performance and fuel efficiency. The tool’s design allows for minimal clearance adjustments, which is vital for maintaining the engine’s optimal performance.

Coordination with Injector Tappet Tool

The Injector Tappet Tool works in tandem with the Top Stop Tappet Lift Tool to provide a comprehensive solution for tappet adjustments. This coordination is essential for maintaining the correct valve clearance, which is a key factor in the engine’s overall performance. Proper tappet adjustment ensures that the valves open and close at the right times, preventing issues such as valvetrain noise and potential engine damage.

Enhancement of Performance Parts

Incorporating the Top Stop Tappet Lift Tool into the maintenance regimen of Performance Parts can significantly enhance the engine’s capabilities. By ensuring that all components, including tappets and injectors, are correctly adjusted, the tool contributes to smoother engine operation, reduced wear, and improved power output. This is particularly important in high-performance engines where precision is paramount.

Overall Impact on Engine Performance

The use of the Top Stop Tappet Lift Tool in engine systems leads to several performance benefits. It ensures that all moving parts within the engine are operating at their peak efficiency. This not only improves the engine’s reliability but also extends its lifespan. Additionally, the tool aids in reducing emissions by ensuring that the fuel injection system is finely tuned, contributing to a more environmentally friendly operation.

Conclusion

In summary, the Part 3823348 Top Stop Tappet Lift Tool plays a significant role in the precise adjustment and maintenance of engine components, directly influencing the engine’s performance and longevity. Its compatibility with specific Cummins engine models, such as the K19, K38, and K50, ensures that maintenance tasks can be performed efficiently and accurately. The tool’s robust design and precise functionality make it an indispensable asset in the maintenance and performance optimization of heavy-duty truck engines.

-

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.