This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

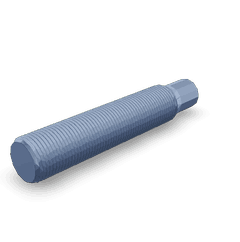

The Cummins 2887476 Continuous Thread Stud is a specialized fastener designed for heavy-duty truck applications. Its purpose is to provide secure and reliable fastening solutions in demanding environments. The significance of this stud lies in its ability to enhance the structural integrity and operational efficiency of commercial trucks.

Basic Concepts of Continuous Thread Studs

Continuous thread studs are fasteners characterized by their uninterrupted thread along the entire length. They function by being screwed into a tapped hole, allowing for the attachment of various components using nuts. In the automotive industry, these studs are commonly used in engine assemblies, chassis construction, and other critical areas where high strength and durability are required 1.

Purpose and Role in Truck Operation

The Cummins 2887476 Continuous Thread Stud plays a specific role in the operation of commercial trucks by securing engine components and other critical parts. It ensures that these components remain firmly in place under various operating conditions, contributing to the overall stability and performance of the truck. Its function in engine and component assembly is vital for maintaining the structural integrity and operational efficiency of the vehicle.

Key Features

The Cummins 2887476 Continuous Thread Stud boasts several key features that enhance its performance and durability. It is typically made from high-strength materials, such as alloy steel, to withstand the rigors of heavy-duty applications. The thread design is precision-engineered to provide a secure fit and resist loosening over time. Additionally, it may feature unique attributes such as corrosion-resistant coatings to improve longevity in harsh environments.

Benefits

Using the Cummins 2887476 Continuous Thread Stud offers several benefits. It provides improved reliability due to its robust construction and precise threading. The ease of installation is another advantage, as the continuous thread design allows for straightforward attachment and removal of components. Furthermore, it enhances structural integrity in truck assemblies, ensuring that critical parts remain securely fastened during operation.

Installation Process

Proper installation of the Cummins 2887476 Continuous Thread Stud involves several steps. Begin by ensuring the tapped hole is clean and free of debris. Insert the stud into the hole and screw it in using a wrench, taking care not to over-tighten. It is important to follow torque specifications to avoid damaging the stud or the surrounding components. Best practices include using a thread lubricant to facilitate installation and reduce the risk of galling.

Troubleshooting and Maintenance

Common issues with continuous thread studs may include loosening, corrosion, or damage from over-tightening. Troubleshooting these problems involves inspecting the stud and surrounding components for signs of wear or damage. Maintenance tips to ensure longevity and optimal performance include regular inspection for signs of corrosion or loosening, and re-torqueing as necessary to maintain proper fastening.

Comparative Analysis

When compared to other types of fasteners and studs, the Cummins 2887476 Continuous Thread Stud offers distinct advantages. Its continuous thread design provides a more secure attachment than traditional bolts, reducing the risk of loosening over time. However, it may be more complex to install in certain applications, requiring precise threading and torque specifications. The choice between continuous thread studs and other fasteners depends on the specific requirements of the application.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is committed to producing high-quality components for commercial vehicles, including engines, powertrains, and aftermarket parts. Cummins’ dedication to innovation and excellence ensures that their products, such as the 2887476 Continuous Thread Stud, meet the demanding needs of heavy-duty truck applications.

Continuous Thread Stud Part 2887476 Compatibility with Cummins Engines

The Continuous Thread Stud part number 2887476, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines, including the QSK95 CM2350 K111 and QSK95 CM2350 K113 models. This part is crucial for ensuring the secure fastening of components within these engines, contributing to their overall structural integrity and operational efficiency.

In the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Continuous Thread Stud part 2887476 is employed in various applications where a robust and reliable connection is necessary. This includes securing engine components, ensuring that they remain firmly in place under the demanding conditions these engines operate in.

The design of the Continuous Thread Stud part 2887476 is such that it can withstand the high stresses and varying temperatures encountered in engine environments. Its compatibility with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines is a testament to Cummins’ commitment to providing high-quality, durable parts that meet the stringent requirements of these engines.

By using the Continuous Thread Stud part 2887476, engine manufacturers and technicians can ensure that the engines maintain their performance and longevity. This part’s integration into the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines highlights its importance in the overall maintenance and repair processes of these engines.

Role of Part 2887476 Continuous Thread Stud in Engine Systems

The part 2887476 Continuous Thread Stud is integral to the assembly and functionality of several key engine components.

In the camshaft system, this stud ensures secure attachment of the camshaft to the cylinder head, allowing for precise valve timing and operation. Its continuous thread design facilitates easy installation and removal, which is essential during maintenance or upgrades.

Within a camshaft kit, the Continuous Thread Stud plays a similar role, providing a robust connection that can withstand the high stresses and vibrations inherent in engine operation. This reliability is particularly important in performance applications where camshafts are often upgraded for increased engine output.

For the connecting rod and piston assembly, although the stud itself may not directly interface with these components, its role in securing the cylinder head—where the combustion process occurs—indirectly supports the efficient transfer of force from the piston to the crankshaft via the connecting rod.

The cylinder head benefits significantly from the use of the Continuous Thread Stud. By providing a strong, vibration-resistant mount for the camshaft, it helps maintain the integrity of the valve train. This is vital for consistent valve operation, which directly impacts engine performance and longevity.

In the realm of performance parts, the Continuous Thread Stud is often utilized in high-performance engine builds. Its design allows for easier adjustments and modifications, which are common in tuning and upgrading engines for enhanced performance. The stud’s ability to handle increased stress and vibration makes it a preferred choice for performance applications where reliability under extreme conditions is paramount.

Conclusion

The Cummins 2887476 Continuous Thread Stud is a critical component in heavy-duty truck and engine applications. Its design, featuring continuous threading and high-strength materials, ensures secure fastening and durability under demanding conditions. Proper installation and maintenance are essential to maximize its benefits and ensure the longevity and performance of the vehicle or engine it is used in.

-

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.