This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

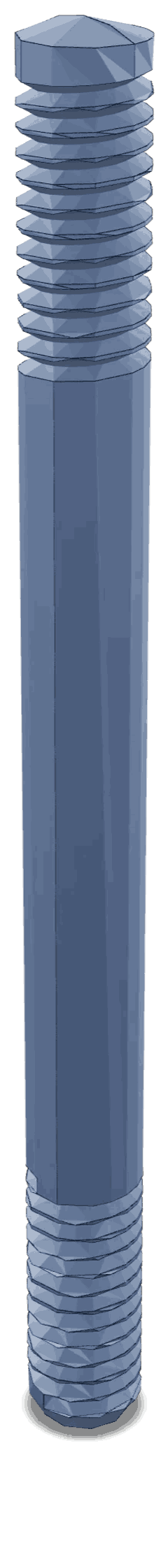

The Cummins 3002185 Double End Plain Stud is a specialized component designed for use in commercial truck maintenance and operation. This part is integral to ensuring the mechanical integrity and performance of trucks, particularly in high-stress environments where reliability and durability are paramount.

Basic Concepts of Double End Plain Studs

A Double End Plain Stud is a type of fastener characterized by having threaded sections on both ends and no head. This design allows it to be used in applications where traditional bolts or screws may not be suitable. The stud is typically installed through pre-drilled holes in mechanical components and secured with nuts on both ends. This configuration provides enhanced strength and stability compared to single-ended fasteners. Double end plain studs find applications across various industries, including automotive, aerospace, and heavy machinery, where they are used to join components that experience significant stress and vibration 1.

Role of the 3002185 Double End Plain Stud in Truck Operation

In the context of commercial trucks, the 3002185 Double End Plain Stud plays a specific role in maintaining the structural integrity of critical components. It is often used in engine assemblies, transmission systems, and other areas where high tensile strength and resistance to vibration are required. By securely fastening components together, this stud contributes to the overall functionality and performance of the truck, ensuring that parts remain aligned and operational under demanding conditions.

Key Features of the 3002185 Double End Plain Stud

The 3002185 Double End Plain Stud is distinguished by several key features. It is constructed from high-quality materials, typically a grade of steel that offers excellent strength and corrosion resistance. The stud has precise thread specifications to ensure a secure fit and optimal performance. Additionally, its design includes features that enhance its durability and ease of installation, such as chamfered ends for smooth threading and consistent pitch across the threaded sections.

Benefits of Using the 3002185 Double End Plain Stud

Incorporating the 3002185 Double End Plain Stud into truck maintenance and repair offers several advantages. Its durable material composition and precise manufacturing ensure long-lasting performance even in harsh operating conditions. The stud’s design also facilitates easy installation, reducing downtime during maintenance procedures. Furthermore, its reliability minimizes the risk of component failure, contributing to safer and more efficient truck operations.

Installation and Usage Guidelines

Proper installation of the 3002185 Double End Plain Stud is crucial for ensuring its effectiveness. Begin by aligning the stud with the pre-drilled holes in the components to be joined. Insert the stud and secure it with nuts on both ends, ensuring that the nuts are tightened to the manufacturer’s specified torque settings. This step is vital to prevent over-tightening, which can damage the stud or the components, and under-tightening, which can lead to loosening and potential failure. Alignment should be checked to ensure that the components are properly mated.

Troubleshooting Common Issues

Common issues with double end plain studs include loosening due to vibration, corrosion, and wear. Signs of these problems may include increased vibration, unusual noises, or visible damage to the stud or surrounding components. To address these issues, regularly inspect the studs for signs of wear or corrosion. If any issues are detected, the stud should be replaced to prevent further damage. Additionally, ensuring that the stud is properly torqued during installation can help mitigate these problems.

Maintenance Recommendations

To ensure the longevity and optimal performance of the 3002185 Double End Plain Stud, routine maintenance practices should be followed. This includes regular inspections for signs of wear, corrosion, or damage. The intervals for these inspections should be based on the operating conditions and the manufacturer’s recommendations. If any studs show signs of significant wear or failure, they should be replaced promptly to maintain the integrity of the truck’s components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s product range includes engines for on-highway and off-highway applications, as well as power generation equipment and component solutions. Cummins’ dedication to excellence is evident in its rigorous testing and quality control processes, ensuring that its products meet the highest standards of performance and reliability 2.

Role of Part 3002185 Double End Plain Stud in Engine Systems

The part 3002185 Double End Plain Stud is integral to the assembly and functionality of several key components within engine systems. Its role can be observed in the following applications:

Fan Drive Arrangement

In the fan drive arrangement, the Double End Plain Stud serves as a pivotal fastening element. It secures the fan drive components, ensuring that the fan operates efficiently and remains aligned with the engine’s rotational axis. This stud contributes to the stability and reliability of the fan drive system, allowing for optimal cooling performance.

Fan Drive Mtg. (Fan Drive Mounting)

For the fan drive mounting, the Double End Plain Stud is employed to anchor the fan drive to the engine block or other structural components. This secure attachment is essential for withstanding the dynamic forces generated during engine operation, thereby maintaining the integrity of the fan drive system.

Fan Mounting Hub

Within the fan mounting hub, the Double End Plain Stud plays a significant role in connecting the fan blades to the fan drive mechanism. This connection ensures that the fan rotates smoothly and effectively, contributing to the overall cooling efficiency of the engine system.

Heat Exchanger

In the context of the heat exchanger, the Double End Plain Stud is used to fasten various components of the heat exchanger assembly. This includes securing the heat exchanger to the engine block or other supporting structures. The stud’s robust design ensures that the heat exchanger remains firmly in place, facilitating efficient heat transfer and maintaining the engine’s optimal operating temperature.

Kit Spare (Heat Ex. Cooled)

For the kit spare involving a heat exchanger-cooled system, the Double End Plain Stud is a vital component in the assembly process. It is used to secure spare parts or additional components within the heat exchanger system, ensuring that these elements are properly installed and function as intended. This contributes to the reliability and maintainability of the engine’s cooling system.

Conclusion

The Cummins 3002185 Double End Plain Stud is a critical component in the maintenance and operation of commercial trucks. Its robust design, precise manufacturing, and reliable performance make it an essential part in ensuring the structural integrity and functionality of engine systems. Proper installation, regular maintenance, and timely replacement of worn or damaged studs are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.