This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Double End Plain Stud (Part #3092377) manufactured by Cummins is a specialized fastener designed for use in commercial truck operations. This component is integral to maintaining the structural integrity and performance of various truck systems. Its robust design and precise engineering make it a reliable choice for heavy-duty applications, ensuring that critical components remain securely fastened under demanding conditions 1.

Basic Concepts and Functionality

A Double End Plain Stud is a type of fastener that features threads on both ends, allowing it to be screwed into two separate components. Within a truck’s mechanical system, this stud plays a role in connecting and securing various parts, contributing to the overall stability and functionality of the vehicle. By providing a strong and durable connection, the Double End Plain Stud helps maintain the structural integrity of the truck, ensuring that components remain aligned and operational under stress 2.

Purpose of the Double End Plain Stud

The Double End Plain Stud serves a specific role in the operation of a truck by securing critical components in place. It is commonly used in applications where high tensile strength and resistance to vibration are required. This includes connections in engine components, transmission systems, and chassis structures. By ensuring that these parts remain firmly attached, the stud contributes to the reliable performance and longevity of the truck 3.

Key Features

The Double End Plain Stud is characterized by several key features that make it suitable for heavy-duty applications. These include a high-quality material composition, typically consisting of alloy steel, which provides excellent strength and durability. The stud also features precise thread specifications to ensure a secure fit, and dimensional accuracy to maintain consistent performance across applications. These design elements contribute to its reliability in demanding environments.

Benefits

Using the Double End Plain Stud in truck maintenance and assembly offers several advantages. Its enhanced durability ensures long-lasting performance, reducing the need for frequent replacements. The stud’s reliable design contributes to the overall reliability of the truck, minimizing downtime. Additionally, its ease of installation simplifies maintenance procedures, allowing for efficient assembly and disassembly when necessary.

Installation and Usage

Proper installation of the Double End Plain Stud is vital to ensure optimal performance and longevity. Installation procedures should follow manufacturer guidelines, including the use of appropriate torque specifications to achieve the correct tension without over-tightening. Best practices involve cleaning the installation surfaces to remove any debris or contaminants that could affect the stud’s grip. Using a torque wrench to apply the specified torque ensures that the stud is securely fastened without risking damage to the threads or surrounding components.

Troubleshooting and Maintenance

Common issues with the Double End Plain Stud may include loosening due to vibration or corrosion. Diagnostic methods for identifying problems involve regular inspections for signs of wear, corrosion, or loosening. Maintenance tips to prevent failures and extend service life include applying an anti-seize compound to the threads during installation to reduce the risk of corrosion and seizing. Additionally, periodic checks and re-torquing, as necessary, help maintain the stud’s integrity over time.

Safety Considerations

When handling and installing the Double End Plain Stud, it is important to observe safety guidelines to ensure the safety of personnel and the integrity of the truck. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect against injury. Ensuring that the work area is clean and free from hazards also contributes to a safe working environment. Following manufacturer instructions and torque specifications helps prevent accidents and ensures the stud is installed correctly.

Cummins Corporation Overview

Cummins Corporation is a leading manufacturer in the automotive and heavy-duty truck industry, known for its wide range of high-quality products. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and durable components. The company’s commitment to quality and performance is evident in its product offerings, which are designed to meet the demanding requirements of commercial truck operations.

Cummins Double End Plain Stud 3092377 Compatibility with Engine Models

The Cummins Double End Plain Stud part number 3092377 is designed to fit seamlessly within several of Cummins’ engine models. This part is integral to the structural integrity and operational efficiency of the engines, ensuring secure connections and reliable performance.

QSK78 CM500 and QST30 CM2350 T101

The Double End Plain Stud 3092377 is compatible with both the QSK78 CM500 and the QST30 CM2350 T101 engines. These engines are known for their robust design and high performance, often used in demanding applications such as marine and industrial settings. The stud’s design allows it to provide a secure fastening solution, critical for maintaining the alignment and stability of various engine components.

QST30 CM552

Similarly, the QST30 CM552 engine also benefits from the use of the Double End Plain Stud 3092377. This engine, like its counterparts, relies on precision and durability in its components to deliver consistent power and longevity. The stud’s double-ended functionality ensures that it can be used in multiple configurations, enhancing its versatility and utility within the engine’s architecture.

Application Considerations

When integrating the Double End Plain Stud 3092377 into these engines, it is essential to consider the specific requirements and operational conditions of each engine model. Proper installation and maintenance of this part are crucial to ensure optimal performance and longevity of the engine components.

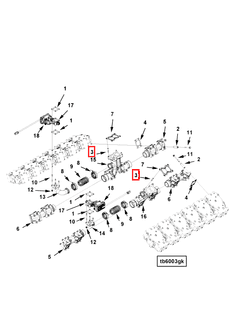

Role of Part 3092377 Double End Plain Stud in Engine Systems

In the intricate assembly of engine systems, the part 3092377 Double End Plain Stud serves as a pivotal component, facilitating the secure attachment and alignment of various elements.

Turbocharger Arrangement

Within the turbocharger arrangement, the Double End Plain Stud is instrumental in connecting the turbocharger to the engine block or the exhaust manifold. This secures the turbocharger in place, allowing it to efficiently compress the intake air, thereby enhancing engine performance and power output. The stud ensures that the turbocharger remains firmly attached, even under the high stresses and temperatures encountered during operation.

Manifold Attachment

In the context of the manifold, whether it be the intake or exhaust manifold, the Double End Plain Stud plays a key role in maintaining the integrity of the manifold-to-engine connection. It ensures that the manifold is properly aligned and sealed, preventing any leaks that could compromise engine efficiency. The stud’s design allows for easy installation and removal, facilitating maintenance and repairs.

Exhaust System Integration

When integrating the exhaust system, the Double End Plain Stud is used to connect the exhaust manifold to the exhaust pipe or catalytic converter. This connection is vital for the efficient flow of exhaust gases away from the engine, reducing backpressure and improving overall engine performance. The stud’s robust construction ensures that it can withstand the high temperatures and pressures of the exhaust system, providing a reliable and durable connection.

Conclusion

In summary, the Double End Plain Stud (Part #3092377) is a fundamental component in the assembly and operation of engine systems, ensuring secure and efficient connections across various critical components. Its robust design, precise engineering, and compatibility with Cummins’ engine models make it an essential part for maintaining the structural integrity and performance of commercial trucks.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

SAE International. Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.