This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

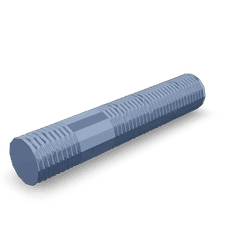

The Cummins 3163823 Stud is a specialized component designed for use in heavy-duty truck operations. It serves a pivotal role in ensuring the secure fastening of various truck components. A stud, in general, is a threaded fastener that is inserted into a tapped hole and secured with a nut. Unlike bolts, which have an integrated head, studs provide a more robust and durable fastening solution, particularly in high-stress applications 4.

Basic Concepts of a Stud

A stud is defined as a threaded rod that is used to fasten two or more components together. It differs from bolts and screws primarily in its design and application. While bolts and screws have heads that allow for tightening with a wrench or screwdriver, studs require a nut to be tightened or loosened. This design allows studs to offer superior strength and durability in mechanical assemblies, making them ideal for applications where high tensile strength and resistance to vibration are required 1.

Purpose of the Cummins 3163823 Stud

This Cummins part plays a specific role in the operation of heavy-duty trucks by contributing to the structural integrity and performance of various components. It is commonly used in the engine and chassis systems, where it helps to secure critical parts under high stress and vibration conditions. Its application ensures that components remain firmly in place, enhancing the overall reliability and safety of the truck 2.

Key Features

This part is designed with precision to meet the demanding requirements of heavy-duty applications. It is typically manufactured from high-tensile steel or alloy, materials known for their strength and durability. The stud features specific thread pitch and size specifications to ensure a secure fit. Additionally, it may be coated or treated to enhance corrosion resistance, further extending its lifespan in harsh operating environments 3.

Benefits

Using this part offers several advantages in truck maintenance and repair. Its high-tensile strength and durable construction provide improved reliability and longevity compared to alternative fastening methods. This results in enhanced safety and performance, particularly in demanding operating conditions where components are subjected to significant stress and vibration 4.

Installation Process

Proper installation of the 3163823 involves a series of steps to ensure a secure and effective fit. The process requires specific tools and equipment, such as a torque wrench, to achieve the correct tightening specifications. Best practices include cleaning the mating surfaces, applying the appropriate lubricant, and tightening the nut to the manufacturer’s recommended torque settings. This ensures that the stud is properly secured without over-tightening, which could lead to damage 1.

Troubleshooting and Maintenance

Common issues associated with studs include loosening due to vibration, corrosion, and wear. Regular inspection and maintenance are crucial to prolong the life of the 3163823. This involves checking for signs of corrosion, ensuring nuts are properly tightened, and replacing studs that show signs of wear or damage. Following these maintenance tips helps to maintain the integrity and performance of the fastening system 2.

Safety Considerations

When working with studs, it is important to follow safety protocols to avoid accidents and component failure. This includes using the correct tools, adhering to manufacturer guidelines, and ensuring that all components are properly installed and maintained. Safety measures help to protect both the equipment and the individuals working on it, ensuring a safe working environment 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. The company has a long-standing reputation for quality and innovation in the heavy-duty truck industry. Cummins is committed to providing reliable and efficient components that meet the needs of its customers, ensuring optimal performance and durability in demanding applications 4.

Role of Part 3163823 Stud in Engine Systems

The 3163823 is integral to the functionality and maintenance of various engine components. When working with a Gear Remover, this stud component facilitates the secure attachment and alignment necessary for the tool’s operation. It ensures that the gear remover can apply the required force effectively without slippage, which is essential for the safe and efficient removal of gears from their housings 1.

In addition to its role with the gear remover, the 3163823 is also employed in the installation and removal processes of other engine components. For instance, it plays a significant part in the alignment and securing of engine mounts, ensuring that the engine is properly positioned within the vehicle’s frame. This alignment is vital for the engine’s operational stability and the overall balance of the vehicle 2.

Furthermore, the stud is utilized in the attachment of various sensors and monitoring devices to the engine block. These sensors are critical for real-time data collection on engine performance, temperature, and other operational parameters. The secure fitting provided by the 3163823 ensures that these sensors remain in place and function accurately throughout the engine’s operation 3.

The stud also aids in the installation of aftermarket performance components, such as cold air intakes or exhaust systems. By providing a robust and reliable mounting point, it ensures that these components are securely attached, enhancing both performance and safety 4.

Conclusion

Overall, the 3163823 is a versatile component that supports a wide range of engine maintenance and upgrade activities, contributing to the efficient and safe operation of the engine system. Its robust design, high-tensile strength, and durable construction make it an essential part in the maintenance and performance of heavy-duty trucks.

-

Modern Diesel Technology Light Duty Diesels, Sean Bennett, Cengage Learning, 2012

↩ ↩ ↩ -

Light and Heavy Vehicle Technology, Fourth Edition, MJ Nunney, Butterworth-Heinemann, 2007

↩ ↩ ↩ -

High Speed Off-Road Vehicles, Bruce Maclaurin, Wiley, 2018

↩ ↩ ↩ -

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.