This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

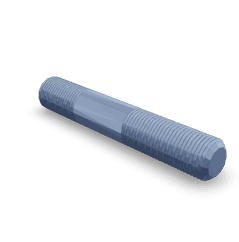

The Double End Plain Stud, identified by Part #3276610, is a component manufactured by Cummins, a prominent name in the heavy-duty truck industry. This stud plays a significant role in various truck components, ensuring the integrity and functionality of critical systems. Cummins is renowned for its high-quality parts and comprehensive product range, making the Double End Plain Stud a valuable component in the maintenance and operation of heavy-duty trucks 2.

Basic Concepts and Functionality

A Double End Plain Stud is a fastener with threaded ends on both sides, designed to secure two or more components together. Its design allows for secure and stable connections, which is vital in the demanding environment of heavy-duty trucks. The stud operates by being inserted through holes in the components and then tightened with nuts on each end, creating a firm hold that can withstand significant stress and vibration 1.

Role in Truck Operation

The Double End Plain Stud serves multiple purposes in truck operation. It is commonly used in engine components, transmission systems, and chassis assemblies. By providing a strong and reliable connection, it supports the structural integrity of these systems. Its applications range from securing engine blocks to transmission housings, ensuring that all parts remain aligned and function correctly under various operating conditions.

Key Features

The Double End Plain Stud is characterized by several key features that enhance its performance and reliability. It is typically made from high-strength materials such as alloy steel, which provides durability and resistance to wear. The stud features a uniform thread type on both ends, ensuring a consistent and secure fit. Additionally, its design may include features like chamfered ends to facilitate easy insertion and reduce the risk of cross-threading.

Benefits

The advantages of using the Double End Plain Stud include enhanced durability, reliability, and performance. Its high-strength material composition ensures it can withstand the rigors of heavy-duty truck operation, reducing the likelihood of failure. The secure connection it provides contributes to the overall stability and efficiency of the truck’s systems, leading to improved performance and longevity.

Installation and Usage

Proper installation of the Double End Plain Stud is crucial for its effectiveness. It should be inserted through the designated holes in the components and secured with nuts on each end. It is important to ensure that the stud is aligned correctly and tightened to the manufacturer’s specified torque settings to achieve the desired level of security and stability. Regular checks during maintenance can help ensure that the stud remains in good condition and properly tightened.

Troubleshooting and Maintenance

Common issues with the Double End Plain Stud may include loosening over time due to vibration or wear. Regular inspections during maintenance can help identify these issues early. If loosening is detected, the stud should be re-tightened to the specified torque settings. In cases of significant wear or damage, replacement may be necessary to maintain the integrity of the connection. Proper lubrication during installation can also help prevent seizing and facilitate easier maintenance.

Safety Considerations

When working with the Double End Plain Stud, it is important to observe several safety guidelines. Ensure that the truck is securely parked and the engine is off before beginning any work. Use the appropriate tools to install and tighten the stud to avoid damage. Wear protective gear, such as gloves and safety glasses, to protect against injury from sharp edges or flying debris. Follow all manufacturer guidelines and safety procedures to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the heavy-duty truck industry. Their comprehensive product range and commitment to customer satisfaction make them a trusted partner for fleet operators and mechanics alike 2.

Applications in Cummins Engines

The Double End Plain Stud part number 3276610, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to provide robust support and stability, ensuring the engine operates smoothly and efficiently.

ISM CM570 and QSM11 CM570

Both the ISM CM570 and QSM11 CM570 engines benefit from the Double End Plain Stud. These engines are known for their reliability and performance in various applications, including heavy-duty trucks and industrial machinery. The Double End Plain Stud is integral to maintaining the structural integrity of these engines, particularly in areas where high torque and stress are common.

L10 MECHANICAL

The L10 MECHANICAL engine, another robust and dependable model, also utilizes the Double End Plain Stud. This engine is often found in construction equipment and agricultural machinery, where durability and strength are paramount. The Double End Plain Stud ensures that the engine components remain securely fastened, reducing the risk of mechanical failure and extending the engine’s lifespan.

M11 CELECT PLUS

The M11 CELECT PLUS engine, a high-performance model, incorporates the Double End Plain Stud to enhance its operational efficiency. This engine is designed for applications requiring high power output and advanced technology features. The Double End Plain Stud plays a crucial role in maintaining the precision and reliability of the engine’s components, ensuring optimal performance under demanding conditions.

Role of Part 3276610 in Engine Systems

The Double End Plain Stud, identified by part number 3276610, is integral to the secure assembly and operation of various engine components. Its primary function is to provide a robust and reliable connection point, ensuring that components remain firmly in place under the demanding conditions of engine operation.

Connection Points

In engine systems, the Double End Plain Stud is often utilized at connection points where secure fastening is required. It ensures that components are held together with precision, minimizing the risk of misalignment or detachment. This is particularly important in high-vibration environments typical of engine operation.

Exhaust Outlet

At the exhaust outlet, the Double End Plain Stud plays a significant role in maintaining the integrity of the connection between the engine block and the exhaust manifold. This ensures that exhaust gases are efficiently directed away from the engine, contributing to overall engine performance and reducing the likelihood of leaks that could lead to performance issues or safety hazards.

Exhaust Accessory

When integrating exhaust accessories, such as catalytic converters or exhaust sensors, the Double End Plain Stud provides a stable mounting solution. This stability is essential for the accurate functioning of these accessories, as any movement or instability could affect their performance and the data they provide.

Exhaust Connection

In the context of exhaust connections, the Double End Plain Stud ensures that the various sections of the exhaust system are securely joined. This is vital for maintaining the structural integrity of the exhaust system and ensuring that it can withstand the high temperatures and pressures generated during engine operation. A secure connection also helps in reducing noise and preventing exhaust leaks, which can be both a performance and safety concern.

Conclusion

Overall, the Double End Plain Stud is a fundamental component in ensuring the reliable and efficient operation of engine systems by providing essential connection points that withstand the rigors of engine dynamics. Its robust design and high-strength material composition make it a critical part in the maintenance and operation of heavy-duty trucks and various Cummins engine models.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.