3282054

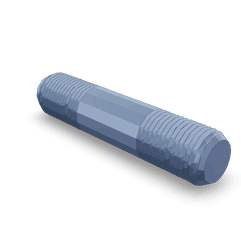

Double End Plain Stud

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Double End Plain Stud (Part #3282054) manufactured by Cummins is a specialized fastener designed for use in commercial truck applications. This component is integral to the assembly and maintenance of various truck components, ensuring secure connections and reliable performance. Its design and functionality are tailored to meet the demanding requirements of heavy-duty truck operations.

Basic Concepts and Functionality

A Double End Plain Stud is a type of fastener characterized by having threads on both ends, allowing it to be screwed into two separate components to hold them together. The structure of this stud typically includes a cylindrical body with uniform threading along its length. This design facilitates secure and stable connections within a truck’s mechanical system. The threading is precision-cut to ensure a tight fit, which is crucial for maintaining the integrity of the assembled components 1.

Purpose and Role in Truck Operation

The Double End Plain Stud plays a significant role in the operation of a truck by providing a robust connection between various components. It is commonly used in applications where high tensile strength and resistance to vibration are required. By securely fastening parts together, it contributes to the overall stability and durability of the truck’s mechanical system. This stud is particularly important in areas where components are subject to significant stress and movement, ensuring that connections remain intact under operating conditions 2.

Key Features

The Double End Plain Stud is manufactured with several key features that enhance its performance and durability. It is typically made from high-strength materials such as alloy steel, which provides excellent resistance to wear and corrosion. The thread pitch is carefully designed to ensure a secure fit, while the plain ends allow for easy installation and removal. Additionally, the stud may feature a polished surface to reduce friction and improve compatibility with other components 3.

Benefits

Using the Double End Plain Stud offers several advantages in truck maintenance and assembly. Its high-strength material composition ensures reliable performance under demanding conditions. The precise threading allows for easy and secure installation, reducing the risk of loosening over time. Furthermore, its compatibility with a wide range of truck components makes it a versatile choice for various applications. The stud’s design also contributes to improved overall reliability and longevity of the truck’s mechanical system.

Installation and Usage Guidelines

Proper installation of the Double End Plain Stud is crucial for ensuring a secure and effective fit. Begin by cleaning the surfaces where the stud will be installed to remove any debris or contaminants. Use a torque wrench to tighten the stud to the manufacturer’s specified torque settings, ensuring a consistent and secure connection. It is important to follow best practices for installation to prevent over-tightening, which can damage the threads, or under-tightening, which can lead to loosening over time.

Troubleshooting and Maintenance

Common issues with the Double End Plain Stud may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these problems early. If loosening is detected, re-tighten the stud to the specified torque settings. In cases of corrosion, clean the affected areas and apply a suitable anti-corrosive coating to prevent further degradation. Regular maintenance and inspection routines will help prolong the lifespan and ensure optimal performance of the stud.

Safety Considerations

When handling and installing the Double End Plain Stud, it is important to observe several safety guidelines. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that the work area is clean and free from hazards. Follow the manufacturer’s torque settings to avoid over-tightening, which can lead to thread damage or component failure. Regular inspection routines should be established to check for signs of wear or damage, ensuring the continued safety and reliability of the truck’s mechanical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company is committed to delivering reliable and high-performance components that meet the rigorous demands of heavy-duty applications. Cummins’ dedication to excellence is evident in their comprehensive range of truck components, including the Double End Plain Stud, which is designed to provide durable and secure connections in commercial truck operations.

Cummins Double End Plain Stud 3282054 Compatibility

The Cummins Double End Plain Stud part number 3282054 is a versatile component designed to fit a variety of Cummins engines. This part is engineered to provide robust and reliable performance across different engine models, ensuring seamless integration and functionality.

Compatible Engines

- 4B3.9

- 6B5.9

- B5.6 CM2670 B152B

- B5.9 GAS PLUS CM556

- B6.7 CM2670 B153B

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

- QSG12/X12 CM2350 G110

- X11 CM2670 X126B

- X12 CM2350 X119B

- X12 CM2670 X121B

- X13 CM2670 X122B

Grouping of Compatible Engines

-

ISB Series:

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

-

ISG Series:

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

-

ISL Series:

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

-

QS/X Series:

- QSG12/X12 CM2350 G110

- X11 CM2670 X126B

- X12 CM2350 X119B

- X12 CM2670 X121B

- X13 CM2670 X122B

-

Other Models:

- 4B3.9

- 6B5.9

- B5.6 CM2670 B152B

- B5.9 GAS PLUS CM556

- B6.7 CM2670 B153B

This Double End Plain Stud is meticulously designed to meet the specific requirements of these engines, ensuring optimal performance and longevity. Whether you are working on an ISB, ISG, ISL, QS/X, or other series, this part is a reliable choice for maintaining and repairing your Cummins engine.

Role of Part 3282054 Double End Plain Stud in Compressor and Air Systems

The Part 3282054 Double End Plain Stud is integral to the efficient operation of compressor and air systems. In compressor systems, this stud is often used to secure components that require robust fastening solutions. Its design allows for secure attachment of parts that experience significant stress and vibration, ensuring the structural integrity of the compressor assembly.

In air systems, the Double End Plain Stud serves a similar purpose by providing a reliable fastening mechanism for components within the air handling units. This includes securing air filters, ductwork connections, and other critical components that must withstand the dynamic forces encountered during operation. The stud’s double-ended design allows for versatile application, accommodating various mounting configurations and enhancing the overall stability of the air system.

Conclusion

The Double End Plain Stud (Part #3282054) is a critical component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its robust design, high-strength material, and precise threading make it an essential fastener for securing various truck components. Proper installation, regular maintenance, and adherence to safety guidelines are vital to ensure the longevity and reliability of this Cummins part. Whether used in compressor systems or air handling units, the Double End Plain Stud plays a pivotal role in maintaining the structural integrity and efficient operation of these systems.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.