This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3395504 Double End Plain Stud is a specialized component designed for heavy-duty truck applications. Its purpose is to provide a secure and reliable connection in various mechanical systems within these vehicles. The significance of this stud lies in its ability to withstand the rigorous demands of heavy-duty operations, ensuring the integrity and performance of the truck’s components 1.

Basic Concepts of Double End Plain Studs

A Double End Plain Stud is a fastener with threaded ends on both sides and no head. It is designed to be inserted through holes in assembled parts, and nuts are then screwed onto each end to hold the parts together. This type of stud is commonly used in applications where frequent disassembly and reassembly are required, or where space constraints prevent the use of traditional bolts and nuts. In the automotive industry, double end plain studs are utilized in engine components, transmission systems, and other critical areas where secure fastening is necessary 2.

Purpose and Role in Truck Operation

The Cummins 3395504 Double End Plain Stud plays a specific role in the operation of heavy-duty trucks by providing a robust connection between components that are subject to high stress and vibration. It ensures that parts remain securely fastened, which is vital for the overall functionality and performance of the vehicle. By maintaining these connections, the stud contributes to the reliability and durability of the truck, allowing it to operate efficiently under demanding conditions 3.

Key Features

The Cummins 3395504 Double End Plain Stud is characterized by several key features that make it suitable for heavy-duty applications. It is typically made from high-strength materials, such as alloy steel, to withstand the rigors of truck operations. The stud has precise thread specifications that ensure a secure fit and proper torque application. Its design is straightforward, with no head, allowing for versatile use in tight spaces and complex assemblies.

Benefits

Using the Cummins 3395504 Double End Plain Stud offers several benefits to heavy-duty trucks. Its durability ensures long-term performance, reducing the need for frequent replacements. The reliability of the stud contributes to the overall stability of the truck’s components, enhancing safety and operational efficiency. Additionally, the stud’s design allows for easier maintenance and repair, as it can be readily accessed and replaced when necessary.

Installation Considerations

When installing the Cummins 3395504 Double End Plain Stud, it is important to follow guidelines and best practices to ensure proper torque specifications are met. Compatibility with other components should be verified to prevent issues during assembly. Careful attention to the stud’s orientation and alignment is necessary to maintain the integrity of the connection. Using the correct tools and following manufacturer recommendations will help achieve a secure and lasting installation.

Troubleshooting and Maintenance

Common issues with double end plain studs may include loosening over time due to vibration or improper torque application. Regular inspection and maintenance are recommended to identify and address any potential problems. Ensuring that nuts are properly tightened and that there is no damage to the stud or surrounding components can help maintain the longevity and optimal performance of the stud.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the manufacturing of automotive components, particularly for heavy-duty trucks. The company’s commitment to excellence is reflected in its products, which are designed to meet the demanding requirements of commercial and industrial applications.

Cummins Double End Plain Stud 3395504 Compatibility

The Cummins Double End Plain Stud part number 3395504 is designed to fit seamlessly within various engine configurations. This component is integral to the structural integrity and operational efficiency of the engines it supports. Below is a detailed look at its compatibility across different engine models.

G855 Engine Series

The G855 engine series is one of the primary applications for the Double End Plain Stud 3395504. This engine series is known for its robust performance and reliability, making it a staple in heavy-duty applications. The part 3395504 is engineered to meet the stringent demands of the G855 engines, ensuring secure fastening and durability under high-stress conditions.

Grouping by Application

In addition to the G855 series, the Double End Plain Stud 3395504 is also compatible with other Cummins engines that share similar design and operational parameters. These engines often require components that can withstand extreme temperatures and pressures, making the 3395504 a versatile choice.

- Heavy-Duty Engines: The 3395504 is particularly suited for heavy-duty engines where reliability and strength are paramount. Its design allows for effective load distribution and minimizes the risk of failure under strenuous conditions.

- Industrial Engines: For industrial applications, the Double End Plain Stud 3395504 provides the necessary stability and security. Its compatibility with various industrial engine models ensures that it can be used across a wide range of machinery and equipment.

Installation and Usage

When installing the Double End Plain Stud 3395504, it is crucial to follow the manufacturer’s guidelines to ensure proper fit and function. This includes using the correct torque specifications and ensuring that the stud is correctly aligned with the mating parts. Proper installation not only enhances the performance of the engine but also extends its lifespan.

By understanding the compatibility of the Double End Plain Stud 3395504 with various Cummins engines, technicians and operators can make informed decisions about maintenance and repairs, ensuring that their engines continue to operate at peak efficiency.

Role of Part 3395504 Double End Plain Stud in Engine Systems

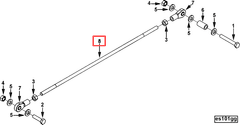

The 3395504 Double End Plain Stud is an essential component in various engine systems, particularly in the linkage and governor control mechanisms.

In the linkage system, this stud serves as a pivotal connection point. It ensures that the mechanical movements are transmitted efficiently from one part of the engine to another. This is particularly important in systems where precise movement and alignment are required to maintain engine performance and reliability.

Within the governor control mechanism, the 3395504 Double End Plain Stud plays a significant role in maintaining the stability and responsiveness of the engine’s speed regulation. It helps in securing the governor components, allowing for smooth and consistent operation. This is vital for engines that require tight control over speed variations, such as those used in industrial applications or high-performance vehicles.

Overall, the integration of the 3395504 Double End Plain Stud in these systems enhances the durability and functionality of the engine, ensuring that all moving parts operate in harmony.

Conclusion

The Cummins 3395504 Double End Plain Stud is a critical component for heavy-duty truck applications, providing secure and reliable connections in various mechanical systems. Its robust design, compatibility with multiple engine models, and role in maintaining engine performance make it an indispensable part of Cummins’ engine systems. Proper installation and maintenance of this stud are essential to ensure the longevity and efficiency of heavy-duty trucks.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.