This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3420611 Fracture Resistant Stud is a specialized component designed to enhance the durability and reliability of heavy-duty truck operations. This stud is engineered to withstand significant stress and resist fractures, which is vital for maintaining the integrity of truck components under demanding conditions.

Basic Concepts of Fracture Resistant Studs

Fracture resistant studs are designed to provide enhanced durability and reliability in mechanical applications. These studs are crafted from materials that exhibit superior resistance to cracking and breaking under stress. The principles of fracture resistance involve the use of advanced material science to create components that can endure high levels of mechanical stress without failing. This is achieved through precise engineering and the selection of materials with optimal tensile strength and fatigue resistance 1.

Purpose and Role in Truck Operation

The 3420611 Fracture Resistant Stud plays a significant role in the operation of heavy-duty trucks by securing critical components that are subject to high stress and vibration. Its primary function is to maintain the structural integrity of engine and transmission mounts, ensuring that these components remain securely in place during operation. This contributes to the overall performance and reliability of the vehicle by preventing unexpected failures and reducing the risk of component detachment 2.

Key Features

The 3420611 Fracture Resistant Stud features a robust design that includes a high-strength alloy composition. This material provides enhanced resistance to fracture and corrosion. The stud is also designed with a threaded end that ensures a secure fit into the corresponding components. Additionally, its surface treatment enhances resistance to wear and environmental factors, contributing to its longevity and performance.

Benefits

Using the 3420611 Fracture Resistant Stud offers several benefits, including improved safety through reduced risk of component failure, enhanced durability that extends the lifespan of critical truck components, reduced maintenance requirements due to its robust design, and increased operational efficiency by ensuring components remain securely in place, minimizing downtime 3.

Installation Process

Proper installation of the 3420611 Fracture Resistant Stud involves several steps. First, the corresponding component should be prepared by cleaning the mounting surface to ensure a secure fit. Next, the stud should be threaded into place using the appropriate torque specifications to avoid over-tightening, which could lead to damage. Tools such as a torque wrench may be required to ensure the stud is installed correctly. Following the manufacturer’s guidelines for installation is recommended to ensure optimal performance and longevity.

Troubleshooting Common Issues

Common issues with fracture resistant studs may include signs of wear, such as corrosion or threading damage, which can lead to reduced effectiveness. Potential causes of failure may involve incorrect installation, exposure to extreme conditions, or mechanical stress beyond the stud’s designed limits. Troubleshooting these issues involves inspecting the stud for signs of damage, ensuring proper installation techniques are used, and replacing the stud if necessary to maintain vehicle safety and performance.

Maintenance Tips

Regular maintenance of the 3420611 Fracture Resistant Stud is important to ensure its longevity and optimal performance. This includes routine inspections for signs of wear or damage, cleaning the stud and its mounting surface to prevent corrosion, and following replacement guidelines if the stud shows signs of significant wear or failure. Adhering to these maintenance practices helps to ensure the continued reliability of the truck’s critical components.

Comparative Analysis

When compared to other similar components in the market, the 3420611 Fracture Resistant Stud by Cummins stands out due to its advanced material composition and robust design. Differences in design and performance may be observed when comparing it to other studs, with Cummins’ product often preferred for its proven reliability and durability in demanding applications.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has built a reputation for delivering reliable and high-performance components. The company’s dedication to excellence is evident in its rigorous manufacturing processes and continuous investment in research and development.

Cummins Fracture Resistant Stud 3420611 Compatibility

The Cummins Fracture Resistant Stud, part number 3420611, is designed to enhance the durability and reliability of various engine systems. This part is compatible with several engine models, ensuring a robust fit across different applications. Here is an overview of its compatibility with the specified engines:

Compatible Engines

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

Grouping by Similarities

The engines listed can be grouped based on their compatibility with the Fracture Resistant Stud 3420611. Here are the groupings:

- QSV81G, QSV91G, QSW/QSV82: These engines share a commonality in their design and operational parameters, making them suitable for the same type of fracture-resistant stud.

- QSV91-G4 CM558/CM700 V102: This engine, while unique in its specifications, is also compatible with the stud due to its robust construction and similar engineering principles.

- QSW27, QSW36, QSW73: These engines, though differing in some specifications, are grouped together due to their shared need for enhanced durability and reliability, which the fracture-resistant stud provides.

By ensuring compatibility across these engines, the Fracture Resistant Stud 3420611 helps maintain the integrity and performance of the engine systems it is installed in.

Role of Part 3420611 Fracture Resistant Stud in Engine Systems

The 3420611 Fracture Resistant Stud is a critical component in various engine systems, ensuring the integrity and performance of several key elements.

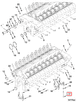

In the cylinder block and cylinder assembly block, this stud plays a significant role in maintaining the structural stability of the engine. It secures critical components such as the camshaft and gear assemblies, ensuring they remain in proper alignment and function efficiently.

Within the cylinder block kit, the stud contributes to the overall robustness of the engine, supporting the mounting of the idler gear and other ancillary components. This ensures smooth operation and reduces the risk of mechanical failure.

The stud is also integral to the oil assembly cooler system. By securing the cooler to the engine block, it helps maintain optimal oil temperature, which is vital for the longevity and performance of the engine.

In engines equipped with prechamber bits, the 3420611 stud ensures these components are firmly attached, enhancing combustion efficiency and overall engine performance.

For engines utilizing the QSV (Quiet Super Vortex) technology, the stud’s role is to secure components that contribute to reduced noise and improved fuel efficiency.

In the D67 engine, the stud is used to fasten various components, ensuring that the engine operates within specified parameters, enhancing reliability and performance.

Overall, the 3420611 Fracture Resistant Stud is a key element in maintaining the structural and functional integrity of these engine systems.

Conclusion

The Cummins 3420611 Fracture Resistant Stud is an essential component for heavy-duty truck operations, providing enhanced durability, reliability, and performance. Its robust design, advanced material composition, and compatibility with various engine models make it a preferred choice for maintaining the integrity of critical engine components. Regular maintenance and proper installation are crucial to ensure the longevity and optimal performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.