This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

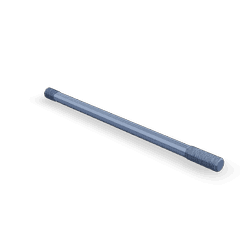

The 3421101 Double Ended Plain Stud, a component manufactured by Cummins, is designed for use in commercial trucks. It plays a role in various mechanical assemblies, contributing to the efficiency and reliability of truck operations.

Basic Concepts of Double Ended Plain Studs

A Double Ended Plain Stud is a fastener with threads on both ends and no head. It is used in mechanical assemblies where bolts and nuts secure components together. This design allows for easier and more consistent torque application compared to traditional bolts 1.

Purpose of the 3421101 Double Ended Plain Stud in Truck Operation

In commercial trucks, the 3421101 Double Ended Plain Stud is used in areas requiring secure and durable fastening, such as engine components and chassis assemblies. It provides a reliable connection that withstands heavy-duty use, contributing to the truck’s stability and performance 2.

Key Features

This Cummins part is crafted from high-quality materials, ensuring durability and resistance to wear and corrosion. Its thread type is designed for a strong grip, enhancing the security of fastened components. Unique design elements, such as precise thread pitch and material treatment, contribute to its performance and longevity in demanding environments 3.

Benefits

Using the 3421101 Double Ended Plain Stud promotes improved reliability in fastening applications, reducing the likelihood of component failure. Its ease of installation simplifies maintenance procedures, allowing for quicker turnaround times. Over time, its durability can lead to potential cost savings by minimizing the need for frequent replacements 4.

Installation Process

Installing the 3421101 requires careful attention to detail. The process involves selecting the appropriate stud size, using the correct tools to insert and tighten the stud, and applying the recommended torque specifications. Following best practices during installation helps to maximize the stud’s performance and lifespan.

Troubleshooting Common Issues

Common issues with Double Ended Plain Studs may include loosening over time or damage from corrosion. Regular inspections are recommended to identify any signs of wear or loosening. In cases where a stud is found to be loose or damaged, it should be replaced with a new one to maintain the integrity of the assembly.

Maintenance Tips

To prolong the lifespan and maintain the efficiency of the 3421101, regular maintenance is advised. This includes periodic inspections to check for signs of wear, corrosion, or loosening. Cleaning the stud and its surrounding area can prevent the buildup of debris that may contribute to wear. Adhering to these maintenance practices helps ensure the continued reliable performance of the stud.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. Their dedication to advancing technology and meeting the needs of their customers underscores their position as a leader in the field of automotive manufacturing.

Cummins Double Ended Plain Stud Part 3421101 Compatibility

The Cummins Double Ended Plain Stud part 3421101 is designed to provide robust and reliable connections in various engine configurations.

QSV81G and QSV91G Engines

The QSV81G and QSV91G engines benefit from the precision and durability of the 3421101 stud. These engines, known for their high performance and efficiency, require components that can withstand significant stress and pressure. The double-ended design of the stud ensures that it can be used in multiple applications within these engines, enhancing their operational reliability.

QSW/QSV82 Engines

The QSW/QSV82 engines also integrate the 3421101 stud effectively. This engine model is designed for versatility and strength, making it suitable for a range of applications. The double-ended plain stud provides a secure and stable connection, which is crucial for maintaining the integrity of the engine’s structure and function.

QSW73 Engine

The QSW73 engine is another model that utilizes the 3421101 stud. This engine is engineered for durability and efficiency, and the stud’s design complements these attributes. By ensuring a tight and reliable connection, the 3421101 stud helps maintain the engine’s performance and longevity.

Part 3421101 Double Ended Plain Stud Component Usage

The 3421101 Double Ended Plain Stud is utilized in various engine systems, facilitating secure connections and ensuring the integrity of the assembly.

Coolant Heater Starting Arrangement

In the context of an Aid system, this stud is utilized to connect and secure the coolant heater starting arrangement to the engine block, providing a stable mounting point that withstands thermal and mechanical stresses during operation.

Thermostat Housing Assembly

Within the Thermostat Housing assembly, the Double Ended Plain Stud plays a significant role in attaching the thermostat housing to the engine block. This secure attachment is vital for maintaining the seal and ensuring that the thermostat operates within the designed parameters, regulating coolant flow and engine temperature effectively.

Engine Assembly Heater System

In the Engine Assembly Heater system, the stud is employed to mount the preheater assembly housing to the engine. This connection is important for the preheater to function correctly, ensuring that the engine reaches optimal operating temperature more quickly, especially in colder climates.

Preheater Mounting Housing

The stud is also integral in the Preheater Mounting Housing, where it provides a robust connection between the preheater and the engine block. This ensures that the preheater remains firmly in place, allowing it to deliver consistent performance and enhance engine start-up in adverse conditions.

Thermostat Assembly Housing and Thermostat Housing Mounting

In the Thermostat Assembly Housing and Thermostat Housing Mounting, the Double Ended Plain Stud ensures that the thermostat is securely fastened. This is important for the accurate regulation of coolant flow, contributing to the engine’s thermal management and overall efficiency.

Thermostat Mounting Housing

Lastly, in the Thermostat Mounting Housing, the stud facilitates a dependable connection, ensuring that the thermostat housing is correctly positioned and sealed. This is essential for the thermostat to function as intended, maintaining engine temperature within the desired range and protecting the engine from potential damage due to overheating or underheating.

Conclusion

The 3421101 Double Ended Plain Stud is a versatile and essential component that fits well with various Cummins engine models. Its design and functionality make it an ideal choice for these engines, providing the necessary support and stability for optimal performance.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Addy Majewski and Hannu Jaskelainen, Diesel Emissions and Their Control: Second Edition, SAE International, 2023.

↩ -

Douglas R. Fehan, Design of Racing and High-Performance Engines 2004-2013, SAE International, 2013.

↩ -

Nicholas Goodnight and Kirk VanGelder, Automotive Braking Systems CDX Master Automotive Technician Series, Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.