This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3421107 Threaded Stud by Cummins is a specialized component designed for use in commercial truck operations. This part serves a role in ensuring the secure attachment of various components within the truck’s engine and chassis systems. A threaded stud is a fastener with external threading that is screwed into a tapped hole, providing a stable anchor point for nuts and other components. In the automotive industry, threaded studs are commonly used for their reliability and ease of installation in high-stress applications.

Basic Concepts of Threaded Studs

Threaded studs consist of a cylindrical body with threads along its length. They function by being screwed into a pre-tapped hole, allowing for the secure attachment of nuts or other threaded components. The threading process involves cutting grooves into the stud to create either coarse or fine threads. Coarse threads are typically used for general-purpose applications, while fine threads offer greater precision and are often used in more specialized applications. Threaded studs are favored in mechanical and automotive applications for their strength, durability, and the ability to withstand repeated tightening and loosening without significant wear 1.

Purpose and Role of 3421107 Threaded Stud in Truck Operations

The 3421107 Threaded Stud plays a specific role in commercial truck operations by providing a robust connection point for critical components. It is designed to withstand the high stresses and vibrations encountered in heavy-duty truck environments. This stud contributes to the overall functionality and safety of the vehicle by ensuring that components remain securely attached, which is particularly important in applications involving the engine, transmission, and chassis. By supporting these systems, the 3421107 Threaded Stud helps maintain the integrity and performance of the truck 2.

Key Features of 3421107 Threaded Stud

The 3421107 Threaded Stud is characterized by several key features that enhance its performance and durability. It is typically made from high-strength materials such as alloy steel, which provides excellent tensile strength and resistance to wear. The thread pitch, which refers to the distance between threads, is carefully designed to ensure a secure fit and easy installation. The length of the stud is tailored to meet the specific requirements of its application, ensuring it extends sufficiently into the tapped hole for maximum holding power. Additionally, the stud may feature special coatings or treatments, such as zinc plating, to provide corrosion resistance and extend its service life 3.

Benefits of Using 3421107 Threaded Stud

Using the 3421107 Threaded Stud offers several advantages. Its high-strength material composition and precise thread pitch contribute to improved reliability and enhanced strength, making it well-suited for demanding applications. The corrosion-resistant coatings help protect the stud from environmental factors, ensuring longevity even in harsh conditions. Additionally, the design of the threaded stud allows for ease of installation, reducing downtime during maintenance procedures. Compared to alternative fastening methods, such as bolts, the threaded stud provides a more secure and permanent connection, which is crucial in high-vibration environments 4.

Installation and Usage Guidelines

Proper installation of the 3421107 Threaded Stud is critical to ensure its effectiveness and longevity. The installation process involves screwing the stud into a pre-tapped hole until it is fully seated. It is important to follow the manufacturer’s recommendations for torque settings to avoid over-tightening, which can strip the threads, or under-tightening, which can lead to loosening. Alignment is also crucial; the stud should be positioned correctly to ensure even distribution of force and to prevent stress concentrations. Securing methods, such as lock washers or thread locker, may be used to further enhance the stability of the connection.

Troubleshooting Common Issues

Common issues associated with threaded studs include stripping, corrosion, and loosening. Stripping can occur if the stud is over-tightened or if the material is not strong enough to withstand the applied force. Corrosion may develop in environments with high moisture or chemical exposure, compromising the integrity of the stud. Loosening can happen due to vibrations or insufficient torque. To address these issues, regular inspections should be conducted to identify signs of wear or damage. If stripping occurs, the stud may need to be replaced. Corrosion can be mitigated with proper coatings and regular cleaning, while loosening can be prevented by ensuring correct torque settings and using additional securing methods.

Maintenance Tips

To ensure the longevity and performance of the 3421107 Threaded Stud, regular maintenance is recommended. This includes periodic checks for signs of wear, corrosion, or loosening. Cleaning the stud and surrounding area can help remove dirt and debris that may contribute to corrosion. Lubrication with a suitable grease can reduce friction and wear during operation. It is also important to follow the manufacturer’s guidelines for torque settings during re-installation or adjustments. If the stud shows significant signs of wear or damage, it should be replaced to maintain the integrity of the connection.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the commercial truck industry. Founded in 1919, Cummins has been at the forefront of engine technology and component manufacturing. The company is known for its commitment to quality and innovation, providing reliable and high-performance products for a variety of applications. Cummins’ dedication to excellence is evident in its extensive range of automotive components, including the 3421107 Threaded Stud, which is designed to meet the rigorous demands of commercial truck operations.

Threaded Stud 3421107 Compatibility with Cummins Engines

The Threaded Stud part number 3421107, manufactured by Cummins, is a critical component in various engine configurations. This part is designed to provide secure fastening and stability in engine assemblies, ensuring that components remain properly aligned and secured during operation.

QSV81G and QSV91G Engines

The Threaded Stud 3421107 is compatible with the QSV81G and QSV91G engines. These engines are part of Cummins’ QSV series, which is known for its robust design and reliability in demanding applications. The threaded stud plays a role in maintaining the integrity of the engine’s internal and external components, ensuring smooth operation and longevity.

QSW/QSV82 and QSW73 Engines

Similarly, the Threaded Stud 3421107 is also suitable for the QSW/QSV82 and QSW73 engines. These engines are part of the QSW series, which is designed for applications requiring high performance and durability. The threaded stud’s precision and strength are essential in these engines, where it helps to secure various parts and prevent loosening over time, thereby maintaining the engine’s operational efficiency.

In summary, the Threaded Stud 3421107 is a versatile component that fits seamlessly into the QSV81G, QSV91G, QSW/QSV82, and QSW73 engines, providing the necessary stability and security for these engines to function optimally.

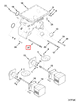

Part 3421107 Threaded Stud Component Usage

The threaded stud, part 3421107, is a component in various engine systems, facilitating secure connections and ensuring the integrity of the assembly. Its role is multifaceted, contributing to the functionality and reliability of several key components.

Air Intake Assembly Manifold

In the air intake assembly manifold, the threaded stud is used to fasten the manifold to the engine block or cylinder head. This secure attachment ensures that the air intake system remains firmly in place, allowing for efficient airflow into the combustion chamber.

Air Outlet Assembly Pipe

For the air outlet assembly pipe, the threaded stud plays a role in connecting the pipe to the turbocharger or other components in the exhaust system. This connection is critical for maintaining the structural integrity of the exhaust path, ensuring that exhaust gases are directed efficiently away from the engine.

Turbocharger Arrangement

Within the turbocharger arrangement, the threaded stud is employed to secure the turbocharger to the engine. This secure attachment is necessary for the turbocharger to operate effectively, providing the necessary boost to the engine’s air intake system.

Charge Air Cooler Assembly

In the charge air cooler assembly, the threaded stud is used to connect the cooler to the intake and outlet pipes. This ensures that the cooled air is efficiently directed into the engine, enhancing combustion efficiency and overall engine performance.

Front Gear Train Accessory

The front gear train accessory often requires the threaded stud to attach various components, such as the drive mechanism, to the engine. This secure connection is essential for the proper functioning of the accessory drive system, which powers critical engine components.

Electronic Governor

For the electronic governor, the threaded stud is utilized to mount the governor to the engine or its housing. This secure attachment ensures that the governor can accurately monitor and control engine parameters, contributing to stable and efficient engine operation.

Intake Assembly Manifold

Similar to the air intake assembly manifold, the intake assembly manifold uses the threaded stud to connect to the engine block or cylinder head. This ensures a tight seal and efficient airflow, which is vital for optimal engine performance.

Manifold Intake Assembly

In the manifold intake assembly, the threaded stud is crucial for securing the manifold to the engine. This connection ensures that the intake system remains intact, allowing for consistent and reliable air delivery to the engine cylinders.

Throttle Valve

The threaded stud is also used in the throttle valve assembly to secure the valve to its housing. This ensures that the throttle valve can operate smoothly and accurately, controlling the airflow into the engine and thus influencing engine performance and fuel efficiency.

Conclusion

The 3421107 Threaded Stud by Cummins is a critical component in commercial truck operations, providing secure and reliable fastening for various engine and chassis components. Its high-strength material, precise thread design, and corrosion-resistant coatings make it well-suited for demanding applications. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential to ensure the longevity and performance of this part. By understanding the role and benefits of the 3421107 Threaded Stud, truck operators and maintenance professionals can ensure the optimal functioning and safety of their vehicles.

-

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4915534, General Information.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.