This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Double End Plain Stud, identified by Part #3426296, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This stud plays a role in the assembly and functionality of heavy-duty truck components, contributing to reliable performance and durability in demanding environments.

Basic Concepts

A Double End Plain Stud is a type of fastener characterized by threaded sections on both ends, allowing it to be screwed into components from both sides. Its structure typically includes a cylindrical body with uniform threading, designed to provide secure fastening without the need for nuts on both ends. In truck mechanics, these studs are utilized to connect various parts securely, ensuring structural integrity and operational efficiency 1.

Purpose and Role in Truck Operation

This Cummins part serves a specific purpose in the operation of heavy-duty trucks. It is commonly used in applications where components need to be fastened together under high stress or where space constraints make traditional bolt and nut configurations impractical. This stud supports critical systems within the truck, contributing to the overall stability and performance of the vehicle 2.

Key Features

The 3426296 Double End Plain Stud is distinguished by several key features that make it suitable for heavy-duty applications. Its material composition typically includes high-strength alloys, ensuring durability and resistance to wear and tear. The threading is precision-cut to provide a secure fit, while the design characteristics are tailored to withstand high stress conditions commonly encountered in heavy-duty truck operations 3.

Benefits

Utilizing the 3426296 Double End Plain Stud offers several advantages. Its robust material composition and precise threading contribute to its durability, allowing it to maintain integrity under demanding conditions. The stud’s design also enhances its resistance to wear and tear, ensuring long-term performance. Furthermore, its ability to withstand high stress conditions makes it an invaluable component in heavy-duty truck mechanics.

Installation Considerations

When installing this part, it is important to follow guidelines and best practices to ensure proper integration and functionality. Torque specifications should be adhered to, ensuring the stud is tightened to the manufacturer’s recommended levels. Compatibility with other components must also be considered, ensuring a secure and reliable connection.

Troubleshooting and Maintenance

Common issues associated with Double End Plain Studs may include loosening over time or damage due to excessive stress. Diagnostic approaches involve inspecting the stud for signs of wear or damage and ensuring it is properly torqued. Maintenance tips include regular inspection and tightening as necessary to ensure longevity and optimal performance.

Safety Precautions

When handling and installing the 3426296 Double End Plain Stud, it is important to observe safety measures to prevent accidents and ensure compliance with industry standards. This includes wearing appropriate personal protective equipment, ensuring the work area is clean and free from hazards, and following all manufacturer guidelines for installation and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive components industry. Its product range includes a variety of engine and component solutions designed to meet the demands of heavy-duty applications.

Compatibility with Engine Models

This Cummins part is designed to fit seamlessly with a variety of engine models. It is integral to the structural integrity and operational efficiency of the engines it is compatible with. Here’s how it fits with the specified engines:

QSV81G, QSV91G, and QSW/QSV82

The Double End Plain Stud 3426296 is engineered to integrate with the QSV81G, QSV91G, and QSW/QSV82 engines. These engines are part of the Cummins QSV series, known for their robust design and reliability in various industrial applications. The stud’s precision-engineered dimensions ensure it fits perfectly within the specified engine models, providing a stable connection point for critical components.

QSV91-G4 CM558/CM700 V102

For the QSV91-G4 CM558/CM700 V102 engine, the Double End Plain Stud 3426296 is meticulously designed to match the engine’s specific requirements. This engine model is part of the Cummins QSV series, which is renowned for its durability and performance. The stud’s compatibility with this engine ensures that it can withstand the rigorous demands of heavy-duty operations, maintaining the engine’s structural integrity over time.

QSW73

The QSW73 engine also benefits from the Double End Plain Stud 3426296. This engine model is another member of the Cummins QSW series, which is designed for high-performance applications. The stud’s compatibility with the QSW73 ensures that it can handle the stresses and strains of demanding environments, providing a reliable connection point for essential engine components.

Each of these engines relies on the Double End Plain Stud 3426296 to maintain operational efficiency and longevity. The stud’s design ensures it fits perfectly within the specified engine models, providing a stable and reliable connection point for critical components.

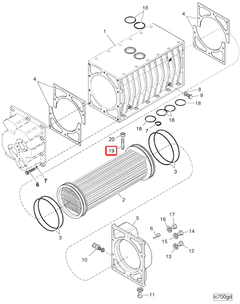

Role of Part 3426296 Double End Plain Stud in Engine Systems

The 3426296 Double End Plain Stud is instrumental in securing and maintaining the integrity of various engine components. In the context of an Engine Oil Cooler, this stud ensures a robust connection between the cooler and the Engine Oil Assembly Cooler. This connection is vital for the efficient transfer of heat away from the engine oil, thereby maintaining optimal operating temperatures.

Within the Oil Cooler Assembly Housing, the Double End Plain Stud plays a significant role in securing the housing to the engine block or other structural components. This ensures that the oil cooler remains in the correct position and orientation, facilitating effective cooling of the engine oil as it circulates through the system.

In arrangements involving the Electronic Control Module Kit and Fuel Control Module, the stud is used to fasten these modules to the engine or chassis. This secure attachment is essential for the modules to function correctly, as any movement or vibration could interfere with their operation, potentially leading to inaccurate readings or control signals.

Furthermore, in the Fuel Control system, the Double End Plain Stud is employed to connect various components within the fuel delivery system. This includes securing fuel lines, sensors, and other critical elements, ensuring that the fuel system operates smoothly and efficiently.

Overall, the 3426296 Double End Plain Stud is a fundamental component in maintaining the structural integrity and operational efficiency of various engine systems, including the oil cooling, electronic control, and fuel control modules.

Conclusion

The 3426296 Double End Plain Stud by Cummins is a critical component in the assembly and operation of heavy-duty truck engines. Its robust design, precise threading, and compatibility with various engine models make it an essential part for ensuring the structural integrity and operational efficiency of engine systems. Proper installation, maintenance, and adherence to safety precautions are vital for maximizing the performance and longevity of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.