This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

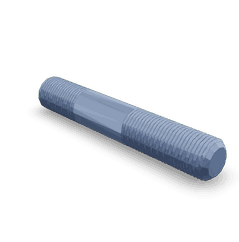

The Double End Plain Stud (Part #3904513) by Cummins is a specialized fastener designed for heavy-duty truck applications. It serves as a pivotal component in securing various parts within the truck’s mechanical system, ensuring stability and reliability under demanding conditions.

Basic Concepts

A Double End Plain Stud is characterized by its dual-threaded design, allowing it to be screwed into components from both ends. This construction facilitates secure fastening in applications where traditional bolts or screws may not provide sufficient strength or stability. Within a truck’s mechanical system, the stud functions by connecting and securing critical components, contributing to the overall integrity and performance of the vehicle 1.

Purpose and Role

The primary purpose of the Double End Plain Stud in truck operations is to provide a robust fastening solution for components that experience significant stress or require precise alignment. It is commonly used in applications such as engine mounting, transmission support, and chassis assembly. By securely fastening these components, the stud plays a role in maintaining the structural integrity and operational efficiency of the truck 2.

Key Features

The Double End Plain Stud is engineered with several key features that enhance its performance and durability. It is typically made from high-strength materials, such as alloy steel, to withstand the rigors of heavy-duty applications. The threading on both ends is precision-cut to ensure a tight and secure fit, while the plain, unheaded design allows for versatile installation in various configurations. Additionally, the stud is designed to resist corrosion and wear, ensuring long-term reliability in harsh operating environments 3.

Benefits

Utilizing the Double End Plain Stud offers several advantages in heavy-duty truck applications. Its robust construction and secure fastening capability contribute to improved mechanical stability, reducing the risk of component failure under stress. The stud’s ease of installation simplifies maintenance procedures, allowing for quick and efficient repairs or replacements. Furthermore, its durability ensures longevity, even in challenging operating conditions, minimizing the need for frequent replacements and reducing overall maintenance costs 4.

Installation Process

Proper installation of the Double End Plain Stud is crucial to ensure optimal performance and safety. Begin by selecting the appropriate stud size and thread pitch for the application. Clean the mating surfaces to remove any debris or contaminants that could affect the stud’s grip. Using a torque wrench, carefully tighten the stud to the manufacturer’s specified torque settings, ensuring even pressure distribution. Avoid over-tightening, as this can lead to thread damage or component stress. Finally, periodically inspect the stud for signs of wear or loosening, and re-torque as necessary to maintain secure fastening .

Maintenance and Troubleshooting

Regular maintenance of the Double End Plain Stud is essential to ensure continued performance and safety. Inspect the stud and surrounding components for signs of wear, corrosion, or damage during routine maintenance checks. Look for any indications of loosening, as this could compromise the fastening integrity. If any issues are detected, address them promptly by re-torquing the stud or replacing it as needed. Additionally, keep an eye out for any unusual vibrations or noises, as these could indicate a problem with the stud or the components it secures .

Safety Considerations

When handling and installing the Double End Plain Stud, it is important to observe several safety guidelines to protect both personnel and the equipment. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to prevent injury from sharp edges or flying debris. Ensure that the truck is securely supported on jack stands or a lift before beginning any work to prevent accidental movement or collapse. Follow the manufacturer’s torque specifications carefully to avoid over-tightening, which could lead to thread stripping or component damage. Finally, be mindful of any potential hazards in the work area, such as electrical components or moving parts, and take appropriate precautions to mitigate risks .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name among fleet operators, equipment manufacturers, and consumers worldwide.

Cummins Double End Plain Stud 3904513 Compatibility

The Cummins Double End Plain Stud, part number 3904513, is a versatile component designed to fit a variety of Cummins engines. This stud is essential for securing components within the engine assembly, ensuring stability and reliability during operation. Below is a detailed look at the engines with which this part is compatible.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B5.9 G

- C GAS PLUS CM556

- C8.3 G

- ISB CM550

- ISC CM554

- ISL CM554

- QSC8.3 CM554

- QSF3.8 CM2350 F107

- QSL9 CM554

Grouping of Compatible Engines

Group 1: 6B5.9, 6C8.3, C8.3 G

The Double End Plain Stud 3904513 is compatible with the 6B5.9, 6C8.3, and C8.3 G engines. These engines share similar design elements and specifications, making this stud a suitable fit for securing various components within these models.

Group 2: ISB CM550, ISC CM554, ISL CM554, QSC8.3 CM554, QSL9 CM554

This group includes the ISB CM550, ISC CM554, ISL CM554, QSC8.3 CM554, and QSL9 CM554 engines. These engines are part of Cummins’ advanced engine series, designed for high performance and durability. The Double End Plain Stud 3904513 is engineered to meet the rigorous demands of these engines, ensuring reliable performance and longevity.

Group 3: 4B3.9, B5.9 G, C GAS PLUS CM556, QSF3.8 CM2350 F107

The remaining engines, 4B3.9, B5.9 G, C GAS PLUS CM556, and QSF3.8 CM2350 F107, also benefit from the use of the Double End Plain Stud 3904513. This stud is designed to fit seamlessly into these engines, providing the necessary support and stability for optimal operation.

Role of Part 3904513 Double End Plain Stud in Engine Systems

The part 3904513 Double End Plain Stud is integral to the secure assembly and operation of various engine components. In the compressor section, this stud ensures the secure attachment of the compressor wheel to the shaft, facilitating efficient air compression and contributing to the overall performance of the engine.

Within the air system, the stud plays a part in maintaining the integrity of connections between different air passages and components, ensuring smooth airflow and pressure regulation.

In the drive system, the Double End Plain Stud is utilized to connect the front and rear gear train accessories to the engine. This connection is vital for the transmission of power from the engine to these accessories, enabling them to function correctly.

For the front gear train accessory, the stud ensures a robust connection to the engine, allowing for the efficient transfer of power to components such as the alternator or water pump. Similarly, in the rear gear train accessory, it secures the attachment to the engine, ensuring reliable operation of components like the power steering pump or air conditioning compressor.

Overall, the part 3904513 Double End Plain Stud is a key component in maintaining the structural integrity and functional efficiency of these engine systems.

Conclusion

The Double End Plain Stud (Part #3904513) by Cummins is a critical component in heavy-duty truck applications, providing robust fastening solutions for various engine components. Its dual-threaded design, high-strength material, and precision-cut threading ensure secure and reliable connections, contributing to the overall performance and durability of the vehicle. Proper installation, regular maintenance, and adherence to safety guidelines are essential to maximize the benefits of this stud and ensure the longevity and efficiency of the truck’s mechanical system.

-

Alan Robinson and Andrew Livesey, The Repair of Vehicle Bodies Fifth Edition, Elsevier, 2006.

↩ -

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩ -

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4358472, ISB/ISD6.7 CM2150 B120.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.