This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

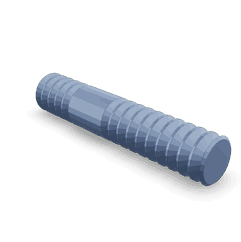

The Double End Plain Stud, part number 3911804, manufactured by Cummins, is a specialized component designed for use in heavy-duty truck applications. This part is significant within the context of heavy-duty truck components due to its role in ensuring the secure attachment of various mechanical parts, contributing to the overall reliability and performance of the vehicle.

Basic Concepts and Functionality

A Double End Plain Stud is a type of fastener characterized by having threads on both ends, allowing it to be screwed into two separate components to hold them together. The design of this Cummins part includes precision threading and is typically made from high-strength materials to withstand the demanding conditions encountered in heavy-duty truck operations. The threading ensures a secure fit, while the material composition contributes to durability and resistance to wear and corrosion 1.

Purpose and Role in Truck Operation

The Double End Plain Stud plays a specific role in the operation of a truck by providing a reliable means of fastening components that are subject to significant stress and vibration. It is commonly used in applications where a permanent fastening solution is required, such as in engine components, transmission systems, and chassis assemblies. Its application ensures that critical parts remain securely attached, contributing to the safe and efficient operation of the truck 2.

Key Features

The Double End Plain Stud boasts several key features that enhance its performance and reliability. These include a durable material composition that resists corrosion and wear, a precise thread pitch that ensures a secure fit, and a high load-bearing capacity that allows it to withstand significant stress without failure. These features make it an ideal choice for heavy-duty applications where reliability and strength are paramount 3.

Benefits

Utilizing the Double End Plain Stud in truck maintenance and repair offers several advantages. Its design contributes to the reliability of the fastening solution, reducing the risk of component failure. The ease of installation simplifies maintenance procedures, allowing for quick and efficient repairs. Additionally, the longevity of the part ensures that it can withstand the rigors of heavy-duty truck operation, providing lasting performance.

Installation and Usage

Proper installation of the Double End Plain Stud is crucial for ensuring its effectiveness and longevity. Best practices include using the correct torque specifications to avoid over-tightening, which can lead to damage, and ensuring that the stud is properly aligned with the components it is fastening. Common applications within truck maintenance include securing engine components, transmission parts, and chassis assemblies.

Troubleshooting and Maintenance

To troubleshoot common issues related to the Double End Plain Stud, it is important to inspect for signs of wear, corrosion, or damage. Regular maintenance, including checking for proper torque and alignment, can help ensure the longevity and optimal performance of the stud. Addressing any issues promptly can prevent more significant problems and contribute to the overall reliability of the truck.

Cummins: Manufacturer Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive industry, particularly in the production of diesel engines and related components. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins’ extensive experience and expertise in the field ensure that their products, including the Double End Plain Stud, meet the high standards required for heavy-duty truck applications.

Compatibility of Double End Plain Stud 3911804 with Cummins Engines

The Double End Plain Stud, part number 3911804, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for securing components within the engine assembly, ensuring stability and reliability during operation. Here’s how it integrates with specific Cummins engines:

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ B Series line, known for their robust performance and durability. The Double End Plain Stud 3911804 is compatible with these engines, providing a reliable connection point for various engine components. Its design ensures that it can withstand the stresses and vibrations inherent in these engines, contributing to the overall longevity and efficiency of the engine.

B6.7 CM2670 and B153B Engines

The B6.7 CM2670 and B153B engines are also part of the Cummins B Series, designed for heavy-duty applications. The Double End Plain Stud 3911804 fits seamlessly into these engines, offering a secure fastening solution for critical components. This part’s precision engineering ensures it meets the stringent requirements of these high-performance engines, enhancing their operational reliability.

ISB CM550 Engine

The ISB CM550 engine, part of Cummins’ ISB Series, is renowned for its power and efficiency. The Double End Plain Stud 3911804 is engineered to fit this engine, providing a dependable connection for various parts. Its robust construction ensures it can handle the demanding conditions of the ISB CM550, contributing to the engine’s overall performance and durability.

Grouping of Compatible Engines

The Double End Plain Stud 3911804 is versatile and compatible with a range of Cummins engines, including the B Series (4B3.9, 6B5.9, B6.7 CM2670, B153B) and the ISB Series (ISB CM550). This compatibility highlights the part’s universal design, making it a reliable choice for securing components across different engine models.

Role of Part 3911804 Double End Plain Stud in Various Engine Systems

The 3911804 Double End Plain Stud is a versatile component utilized across multiple engine systems, ensuring secure and reliable connections. In hydraulic pump systems, this stud plays a significant role in fastening components that manage fluid flow and pressure. It ensures that the hydraulic pump operates efficiently by maintaining the integrity of the connections between the pump housing and other critical parts.

In pump systems, whether they are hydraulic or vacuum-based, the 3911804 Double End Plain Stud is essential for securing pump components. This ensures that the pump can withstand operational stresses and maintain a seal, which is vital for the pump’s performance and longevity.

For vacuum pump systems, the stud is used to fasten components that create and maintain vacuum conditions. This is particularly important in applications where precise vacuum levels are required, such as in manufacturing processes or scientific equipment.

In vacuum/hydraulic systems, which combine both vacuum and hydraulic functions, the 3911804 Double End Plain Stud ensures that the transition between these two types of pumps is seamless and secure. This is important for systems that require both high pressure and vacuum conditions, such as in complex industrial machinery.

Overall, the 3911804 Double End Plain Stud is a fundamental component in ensuring that various pump systems operate efficiently and reliably by providing strong, secure connections between critical parts.

Conclusion

The Double End Plain Stud, part number 3911804, is a critical component in heavy-duty truck applications, offering reliable fastening solutions for various engine systems. Its compatibility with a range of Cummins engines, combined with its durable construction and precise engineering, makes it an essential part for maintaining the performance and reliability of heavy-duty trucks.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.