This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

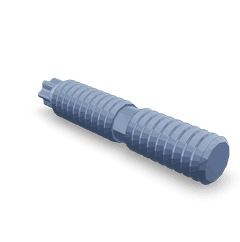

The Cummins 3912843 Stud is a specialized component designed for use in commercial truck operations. It plays a role in ensuring the secure attachment of various engine components, contributing to the overall reliability and performance of the vehicle. Understanding its purpose and functionality is key to maintaining the efficiency and safety of commercial trucks.

Basic Concepts of Studs

A stud is a threaded fastener with external threads on both ends. It is used in mechanical systems to provide a secure connection between components. Unlike bolts, which have a head on one end, studs extend through the components being joined and are typically secured with nuts on both ends. In the automotive industry, studs are commonly used in applications requiring high strength and durability, such as engine assemblies and chassis components 1.

Purpose of the 3912843 Stud

This Cummins part is specifically designed to play a role in the operation of commercial trucks. It is used within the engine to secure critical components, ensuring they remain firmly in place under the high stresses and vibrations encountered during operation. This stud helps maintain the integrity of the engine assembly, contributing to the truck’s overall performance and reliability.

Key Features

The Cummins 3912843 Stud is characterized by several primary features that enhance its performance and durability. It is made from high-quality materials, typically heat-treated alloy steel, to provide superior strength and resistance to wear. The stud features precise threading that ensures a secure fit and optimal torque distribution. Its design specifications are tailored to meet the demanding requirements of commercial truck engines, ensuring long-lasting performance 2.

Benefits

Using the Cummins 3912843 Stud offers several advantages. Its high-strength material composition and precise threading contribute to improved reliability and durability. The stud’s design allows for consistent torque application, reducing the risk of component failure. Additionally, its longevity compared to alternative fastening methods makes it a cost-effective solution for commercial truck maintenance 3.

Installation Process

Proper installation of the Cummins 3912843 Stud is crucial for ensuring optimal performance and safety. The installation process involves several steps:

- Ensure the mating surfaces are clean and free of debris.

- Align the stud with the designated holes in the engine components.

- Thread the stud through the components and secure it with nuts on both ends.

- Tighten the nuts to the specified torque settings using a torque wrench to ensure a secure fit without over-tightening.

Common Issues and Troubleshooting

Studs, including the Cummins 3912843, can encounter issues such as corrosion or stripping. Corrosion can be addressed by regularly inspecting the studs and applying a corrosion-resistant coating if necessary. Stripping can occur due to over-tightening or using the wrong tools. To prevent this, always use the correct torque settings and appropriate tools during installation and maintenance.

Maintenance Tips

Regular maintenance practices can prolong the life of the Cummins 3912843 Stud. Inspection routines should include checking for signs of wear, corrosion, or damage. If any issues are detected, the stud should be replaced according to the manufacturer’s guidelines. Additionally, ensuring that all nuts and components are tightened to the correct specifications during routine maintenance can help prevent future problems.

Safety Considerations

When working with studs, it is important to observe safety protocols and precautions to prevent accidents. This includes wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, and ensuring that all tools and equipment are in good working condition. Following industry standards and manufacturer guidelines for torque settings and installation procedures is also crucial for ensuring safety and compliance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of commercial transportation.

Cummins Engine Part 3912843: Stud Compatibility

The Cummins part 3912843, a Stud, is a critical component in the assembly and maintenance of several Cummins engines. This part is designed to ensure secure fastening and stability in various engine configurations. Below is a detailed description of its compatibility with specific Cummins engines.

4B3.9 Engine

The 4B3.9 engine is a robust and reliable power unit, often utilized in heavy-duty applications. The Stud part 3912843 plays a vital role in this engine by providing essential fastening for various components. Its precision engineering ensures that critical parts remain securely attached, contributing to the engine’s overall durability and performance.

6B5.9 Engine

Similar to the 4B3.9, the 6B5.9 engine benefits significantly from the use of the Stud part 3912843. This engine, known for its power and efficiency, relies on this stud to maintain the integrity of its assembly. The stud’s design allows for reliable fastening, which is crucial for the engine’s operational safety and longevity.

ISB (Chrysler)

The ISB engine, developed in collaboration with Chrysler, is another beneficiary of the Stud part 3912843. This engine is designed for both performance and efficiency, and the stud’s role in securing various components is indispensable. The precision and strength of the stud ensure that the engine operates smoothly and reliably under various conditions.

In summary, the Stud part 3912843 is a fundamental component for the 4B3.9, 6B5.9, and ISB (Chrysler) engines. Its role in maintaining the structural integrity and operational efficiency of these engines cannot be overstated.

Role of Part 3912843 Stud in Engine Systems

Part 3912843 Stud is integral to the assembly and functionality of various engine components. In the context of the fuel system, this stud secures the fuel filter to its support structure, ensuring a stable and leak-free connection. This stability is essential for maintaining consistent fuel flow and pressure, directly influencing engine performance.

Within the hydraulic system, Part 3912843 plays a significant role in mounting the hydraulic pump. It ensures the pump is firmly attached to the engine, allowing for efficient operation and reducing the risk of misalignment or vibration-induced wear. This secure attachment is vital for the pump’s ability to generate and maintain hydraulic pressure, which is necessary for various engine functions, including brake systems and power steering.

Additionally, in vacuum/hydraulic systems, this stud component is used to connect vacuum lines to hydraulic components. This connection is essential for systems that rely on vacuum assistance to operate hydraulic functions, such as certain types of brake boosters. The stud ensures a tight seal, preventing vacuum leaks that could compromise system efficiency.

Overall, Part 3912843 Stud contributes to the reliability and performance of engine systems by providing secure and stable connections between critical components. Its role in maintaining the integrity of fuel, hydraulic, and vacuum/hydraulic systems underscores its importance in engine operation and overall vehicle performance.

Conclusion

The Cummins 3912843 Stud is a critical component in the maintenance and operation of commercial truck engines. Its design and material composition ensure secure fastening and stability, contributing to the overall reliability and performance of the vehicle. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this stud.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.