This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3915036 Stud is a specialized component designed for use in commercial truck applications. Its purpose is to provide secure fastening in various engine components, ensuring the integrity and reliability of the truck’s operation. The significance of this stud lies in its ability to withstand high stress and demanding conditions typical in heavy-duty truck environments 1.

Basic Concepts of Studs

A stud is a threaded fastener with external male threads on both ends, designed to be permanently fixed at one end into a tapped hole. It functions by providing a strong and secure connection between two or more components in mechanical systems. In the automotive industry, studs are commonly used in applications where repeated disassembly and reassembly are required, or where high tensile strength is necessary 2.

Purpose of the Cummins 3915036 Stud

This Cummins part plays a specific role in the operation of a truck by securing critical components within the engine. It is designed to maintain the alignment and integrity of parts under high stress and vibration, ensuring that the engine operates smoothly and efficiently. This stud is integral to the assembly of certain engine components, contributing to the overall performance and durability of the truck 3.

Key Features

The primary characteristics of the 3915036 Stud include its material composition, which is typically a high-strength alloy designed to resist corrosion and wear. The threading on the stud is precision-machined to ensure a secure fit, and its design specifications are tailored to enhance performance and durability under demanding conditions.

Benefits

Using the Cummins 3915036 Stud offers several advantages. It provides improved reliability by ensuring a secure connection between engine components. Enhanced performance is achieved through its robust design, which can withstand high stress and vibration. Additionally, the durability of the stud can lead to potential cost savings for fleet operators by reducing the need for frequent replacements.

Installation and Usage

Proper installation of the 3915036 Stud involves several steps to ensure it is securely fastened. Cummins recommends using the appropriate tools and techniques to achieve the correct torque specifications. This ensures that the stud is properly tightened without over-stressing the component or the surrounding parts.

Troubleshooting and Maintenance

Common issues with the 3915036 Stud may include loosening over time due to vibration or corrosion. Diagnostic tips involve regular inspection for signs of wear or damage. Maintenance practices include cleaning the stud and its mating surfaces, applying the correct lubricant, and ensuring that torque specifications are maintained during reinstallation.

Safety Considerations

When handling, installing, or maintaining the 3915036 Stud, it is important to observe several safety practices. These include wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines to prevent injury or damage to the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications.

Compatibility of Stud Part 3915036 with Cummins Engines

This part is designed to fit a variety of Cummins engines. This part is integral to the assembly and maintenance of these engines, ensuring secure connections and reliable performance. Below is a detailed breakdown of the engines with which this stud is compatible:

6C8.3 and C8.3 G Engines

This part is compatible with the 6C8.3 and C8.3 G engines. These engines are part of Cummins’ lineup of medium-duty diesel engines, known for their durability and efficiency. The stud’s design ensures it can withstand the stresses and vibrations inherent in these engines, providing a stable and secure connection.

G8.3 and L9.3 L105 Engines

The stud also fits the G8.3 and L9.3 L105 engines. These engines are typically used in heavy-duty applications, where reliability and performance are critical. The stud’s robust construction makes it suitable for these demanding environments, ensuring long-term durability and performance.

ISC CM554, ISC CM850, ISL CM554, and ISL9 CM2150 SN Engines

This part is also compatible with the ISC CM554, ISC CM850, ISL CM554, and ISL9 CM2150 SN engines. These engines are part of Cummins’ range of high-performance diesel engines, often used in on-highway and vocational applications. The stud’s precision engineering ensures it can handle the high loads and stresses these engines generate.

QSC8.3 CM554, QSC8.3 CM850(CM2850), QSL9 CM554, and QSL9 CM850(CM2850) Engines

Lastly, the stud is compatible with the QSC8.3 CM554, QSC8.3 CM850(CM2850), QSL9 CM554, and QSL9 CM850(CM2850) engines. These engines are designed for both on-highway and off-highway applications, providing a balance of power and efficiency. The stud’s compatibility with these engines ensures it can meet the diverse demands of these applications, maintaining secure connections under varying conditions.

By ensuring compatibility with these engines, this part plays a crucial role in maintaining the integrity and performance of Cummins engines across a wide range of applications.

Role of Part 3915036 Stud in Engine Systems

This part is integral to the secure assembly and operation of various engine components. Its primary function is to provide a stable connection point, ensuring that components remain firmly in place during engine operation.

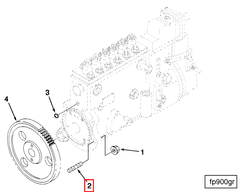

Coupling and Fuel Pump Integration

In the context of the fuel pump, this part plays a significant role in the fuel pump coupling. This stud ensures that the fuel pump is correctly aligned and securely fastened to the engine block. Proper alignment and fastening are essential for the efficient transfer of fuel from the pump to the engine, minimizing the risk of leaks and ensuring consistent fuel delivery.

Front Gear and Cover Assembly

The stud is also utilized in the front gear and front gear cover assembly. By providing a robust mounting point, it helps maintain the precise alignment of the front gear, which is vital for the smooth operation of the engine’s timing mechanism. The front gear cover, which protects the gear from debris and contaminants, is also secured using this stud, ensuring that the cover remains in place and effectively performs its protective function.

Fuel Pump Mounting

When it comes to fuel pump mounting, this part is employed to anchor the fuel pump securely to the engine block. This secure attachment is necessary to withstand the vibrations and stresses encountered during engine operation. It ensures that the fuel pump remains stable, which is essential for maintaining fuel pressure and flow, ultimately contributing to the engine’s overall performance and reliability.

General Mounting Applications

Beyond specific components, this part is a versatile mounting solution used throughout the engine system. It provides a reliable connection point for various engine covers and other components that require secure attachment. This versatility makes it a valuable part in ensuring the structural integrity and operational efficiency of the engine system.

Conclusion

The Cummins 3915036 Stud is a critical component in the assembly and maintenance of Cummins engines, offering reliability, performance, and durability. Its compatibility with a wide range of Cummins engines underscores its importance in ensuring secure connections and efficient operation across various applications.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.