This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Double End Plain Stud, identified by Part #3931377, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This stud plays a role in the assembly and operation of heavy-duty trucks, ensuring the secure connection of various mechanical components. Understanding its function, structure, and the manufacturer’s reputation is key to appreciating its importance in truck maintenance and operation.

Basic Concepts

A Double End Plain Stud is a fastener with threads on both ends, designed to pass through holes in assembled parts and be tightened with nuts on both ends. Its structure is straightforward yet crucial for its function, providing a strong and reliable connection in the mechanical systems of heavy-duty trucks. The stud’s design allows for efficient force distribution and secure fastening, which is vital for the integrity and performance of truck components 1.

Purpose and Role

The primary role of the Double End Plain Stud in truck operations is to connect and secure various components, ensuring they remain firmly in place under the stress of heavy-duty use. It acts as a link in the assembly, contributing to the overall stability and functionality of the truck’s mechanical system. By securing components, it helps maintain alignment and operational efficiency, which are paramount in the demanding conditions heavy-duty trucks often face 2.

Key Features

The Double End Plain Stud is characterized by several key features that enhance its functionality and durability. These include its material composition, typically a high-strength alloy that resists corrosion and wear, and precise threading that ensures a secure fit. The design specifications of the stud, such as its length and diameter, are tailored to meet the specific requirements of heavy-duty truck applications, ensuring optimal performance and longevity 3.

Benefits

Utilizing the Double End Plain Stud offers several advantages. Its design contributes to improved reliability in truck operations, reducing the risk of component failure under stress. The stud’s ease of installation is another benefit, allowing for quick and efficient assembly or replacement. Additionally, its maintenance advantages, such as resistance to wear and corrosion, contribute to the overall durability and cost-effectiveness of truck maintenance.

Installation Process

Proper installation of the Double End Plain Stud involves several steps to ensure a secure and efficient connection. It begins with selecting the correct stud size and ensuring the mating components are properly aligned. The stud is then inserted through the designated holes, and nuts are applied to both ends. Tightening should be done gradually and evenly to avoid over-tightening, which can lead to damage. Following these best practices ensures the stud functions as intended, providing a strong and reliable connection.

Troubleshooting and Maintenance

Common issues with the Double End Plain Stud may include loosening over time or damage from wear and tear. Regular inspection and maintenance are recommended to identify signs of wear or damage early. Maintenance tips include checking for proper torque during installation and ensuring the stud and nuts are free from corrosion. Addressing these issues promptly helps maintain the stud’s functionality and the overall performance of the truck.

Compatibility and Usage

The Double End Plain Stud is commonly used in various applications within heavy-duty trucks, serving as a vital component in the assembly of engines, transmissions, and other mechanical systems. Its compatibility with a wide range of truck models and components makes it a versatile choice for securing and connecting parts, ensuring the truck operates efficiently and reliably.

Safety Considerations

When handling and installing the Double End Plain Stud, it is important to follow safety guidelines to prevent accidents and ensure proper function. This includes wearing appropriate personal protective equipment, ensuring the truck is securely supported during installation, and following torque specifications to avoid over-tightening. Adhering to these safety considerations helps protect both the installer and the integrity of the truck’s mechanical system.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a strong reputation for producing reliable and high-performance components, Cummins continues to lead the way in automotive technology, providing solutions that enhance the efficiency, durability, and safety of vehicles. Their dedication to excellence is evident in the design and manufacturing of components like the Double End Plain Stud, ensuring they meet the rigorous demands of heavy-duty applications.

Cummins Double End Plain Stud 3931377 Compatibility

The Cummins Double End Plain Stud part number 3931377 is designed to fit seamlessly with various engine models, ensuring robust and reliable performance. This part is engineered to meet the stringent requirements of heavy-duty applications, providing critical support and stability within the engine assembly.

Engine Compatibility

-

6B5.9 Series

- The 6B5.9 engine series benefits from the precision and durability of the 3931377 Double End Plain Stud. This part is integral in maintaining the structural integrity of the engine, ensuring that components remain securely fastened and aligned.

-

Group Compatibility

- The 3931377 Double End Plain Stud is also compatible with other Cummins engine groups that share similar design and operational parameters with the 6B5.9 series. This ensures that the part can be used across multiple engine models, providing a versatile solution for engine maintenance and repair.

The use of this part in the 6B5.9 engines and other compatible groups underscores its importance in maintaining engine performance and longevity. Its design allows for easy installation and reliable function, making it a preferred choice for technicians and engineers working with Cummins engines.

Role of Part 3931377 Double End Plain Stud in Engine Systems

The 3931377 Double End Plain Stud is a versatile component that plays a role in ensuring the integrity and functionality of various engine systems. Its primary function is to provide a secure and reliable connection between different parts, which is essential for the overall performance and durability of the engine.

Connection

In engine systems, the 3931377 Double End Plain Stud is often used to connect critical components such as manifolds, brackets, and other structural elements. Its design allows for a robust attachment that can withstand the high stresses and vibrations inherent in engine operation. By securing these components firmly in place, the stud helps maintain the alignment and integrity of the engine’s layout, which is vital for efficient operation.

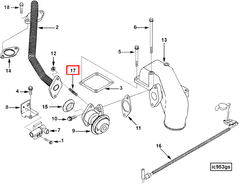

Air Intake

The air intake system is another area where the 3931377 Double End Plain Stud proves invaluable. It is commonly employed to fasten the air intake manifold to the engine block or other supporting structures. This connection ensures that the air intake system remains securely attached, allowing for a consistent and uninterrupted flow of air into the engine. Proper airflow is essential for combustion efficiency, and the stud’s reliable fastening capability contributes to the overall performance and reliability of the air intake system.

By integrating the 3931377 Double End Plain Stud into these engine components, engineers and mechanics can ensure that the engine operates smoothly and efficiently, with all parts securely connected and aligned.

Conclusion

The Double End Plain Stud, part number 3931377, manufactured by Cummins, is a critical component in the assembly and operation of heavy-duty trucks. Its design, characterized by high-strength alloy composition and precise threading, ensures secure and reliable connections in various engine systems. The stud’s compatibility with a wide range of Cummins engine models, including the 6B5.9 series, underscores its versatility and importance in maintaining engine performance and longevity. Proper installation, regular maintenance, and adherence to safety guidelines are essential to maximize the benefits of this Cummins part, contributing to the overall efficiency, durability, and safety of heavy-duty truck operations.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.