This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

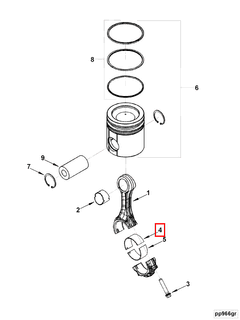

The Cummins 3934725 Connecting Rod Bearing (Stud) is a specialized component designed for use in heavy-duty truck engines. Its purpose is to facilitate the smooth operation of the engine by connecting the piston to the crankshaft. This bearing plays a role in the engine cooling system by ensuring the efficient transfer of power from the piston to the crankshaft, which is vital for the overall performance and reliability of the engine 1.

Function and Operation

The connecting rod bearing (stud) operates within the engine by providing a low-friction interface between the connecting rod and the crankshaft. This bearing allows for the smooth reciprocating motion of the piston to be converted into rotational motion of the crankshaft. The bearing is positioned within the connecting rod, where it interfaces with the crankshaft journal. As the piston moves up and down, the connecting rod bearing enables the connecting rod to pivot smoothly around the crankshaft, minimizing friction and wear 2.

Key Features

The Cummins 3934725 is characterized by several key features that enhance its performance. It is constructed from high-quality materials, typically a combination of steel backing and a bearing overlay, which provides excellent durability and resistance to wear. The design specifications of this bearing include precise tolerances to ensure a proper fit within the connecting rod and crankshaft journal. Additionally, the bearing may feature unique characteristics such as enhanced lubrication grooves to improve oil flow and reduce friction 3.

Benefits

The Cummins 3934725 offers several benefits that contribute to the overall efficiency and reliability of the engine. By reducing friction between the connecting rod and crankshaft, this bearing helps to improve engine efficiency. The high-quality materials and precise design enhance the durability of the bearing, leading to a longer service life. Additionally, the smooth operation of the bearing contributes to the overall reliability of the engine, ensuring consistent performance under demanding conditions.

Installation and Maintenance

Proper installation of the Cummins 3934725 is critical to ensure optimal performance. It should be installed with the correct clearance between the bearing and the crankshaft journal to prevent excessive wear. Regular maintenance practices, such as monitoring oil quality and ensuring proper lubrication, are recommended to maintain the bearing’s performance. Inspecting the bearing for signs of wear or damage during routine engine maintenance can help identify potential issues before they lead to more significant problems.

Troubleshooting

Common issues associated with connecting rod bearings (studs) include excessive wear, noise, and failure. Symptoms of bearing failure may include knocking sounds from the engine, increased oil consumption, or a noticeable decrease in engine performance. Troubleshooting techniques involve inspecting the bearing for signs of wear, checking the clearance between the bearing and crankshaft journal, and ensuring proper lubrication. Corrective actions may include replacing the bearing, adjusting the clearance, or addressing any lubrication issues.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive industry for producing high-quality engine components. Founded in 1919, Cummins has a long history of innovation and commitment to excellence. The company is known for its robust engineering solutions and dedication to manufacturing reliable and durable engine parts. Cummins’ products are widely used in heavy-duty applications, reflecting the brand’s reputation for quality and performance.

Cummins Connecting Rod Bearing (Stud) 3934725 Compatibility

The Cummins Connecting Rod Bearing (Stud) part number 3934725 is designed to fit seamlessly within various engine configurations. This particular bearing is engineered to ensure optimal performance and durability, making it a critical component in the engine’s operation.

Engine Compatibility

4B3.9 Engine Series

The 4B3.9 engine series is one of the prominent applications for the 3934725 Connecting Rod Bearing (Stud). This engine is known for its robust design and reliability, often used in heavy-duty applications. The bearing is specifically crafted to handle the high stresses and loads encountered in these engines, ensuring smooth operation and longevity.

Other Cummins Engines

While the 4B3.9 series is a primary application, the 3934725 Connecting Rod Bearing (Stud) is also compatible with other Cummins engines. This versatility is due to the standardized design and engineering principles that Cummins employs across its engine lineup. The bearing’s precision manufacturing ensures it fits snugly and functions effectively within the specified engine models.

Engine Groups

The 3934725 part number is part of a broader family of connecting rod bearings designed for various engine groups within Cummins’ product range. These groups are categorized based on engine size, application, and performance requirements. The commonality in design allows for easier maintenance and part replacement across different engine models, enhancing operational efficiency and reducing downtime.

By ensuring compatibility with multiple engine configurations, the 3934725 Connecting Rod Bearing (Stud) provides a reliable solution for maintaining the integrity and performance of Cummins engines.

Role of Part 3934725 Connecting Rod Bearing (Stud) in Engine Systems

The Connecting Rod Bearing (Stud), identified as part 3934725, is an essential component in the intricate dance of an engine’s internal mechanisms. Its primary function is to facilitate smooth operation between the connecting rod and the crankshaft, ensuring efficient power transmission from the engine piston to the crankshaft.

Interaction with Engine Piston

The engine piston moves up and down within the cylinder, driven by the combustion process. This reciprocating motion is transferred to the crankshaft via the connecting rod. The Connecting Rod Bearing (Stud) plays a significant role here by providing a low-friction interface that allows the connecting rod to pivot smoothly around the crankshaft journal. This smooth pivoting action is vital for converting the linear motion of the piston into the rotational motion of the crankshaft, which ultimately drives the vehicle.

Integration with Performance Parts

In high-performance engines, where power output and efficiency are paramount, the role of the Connecting Rod Bearing (Stud) becomes even more pronounced. Performance parts often demand higher levels of precision and durability. The bearing stud must withstand increased loads and stresses without compromising on performance. It ensures that the connecting rod maintains optimal alignment with the crankshaft, even under extreme conditions, thereby contributing to the overall reliability and performance of the engine.

Function within the Short Block

The short block, which consists of the engine block, crankshaft, pistons, and connecting rods, is the core of any engine. The Connecting Rod Bearing (Stud) is a linchpin in this assembly, ensuring that the connecting rods are securely attached to the crankshaft while allowing for the necessary movement. This component helps in maintaining the structural integrity of the short block, facilitating the smooth operation of the engine’s moving parts, and contributing to the engine’s longevity and performance.

Conclusion

The Cummins 3934725 Connecting Rod Bearing (Stud) is a critical component in heavy-duty truck engines, ensuring efficient power transmission and smooth operation. Its high-quality construction, precise design, and compatibility with various Cummins engines make it a reliable choice for maintaining engine performance and reliability. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this bearing.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.