This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

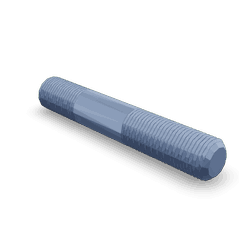

The Double End Plain Stud 3954510, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this component to meet the rigorous demands of heavy-duty applications. This Cummins part is integral to the structural and mechanical integrity of commercial trucks, ensuring reliable performance under demanding conditions.

Basic Concepts of Double End Plain Studs

A Double End Plain Stud is a type of fastener characterized by having threads on both ends, allowing it to be screwed into two separate components. Unlike traditional bolts, which require a nut for securement, double end plain studs provide a more robust connection by threading directly into both mating parts. This design enhances the stability and strength of the connection, making it suitable for applications where high tensile strength and resistance to vibration are required 1.

Role and Function in Truck Operation

The 3954510 Double End Plain Stud plays a significant role in truck mechanics by connecting critical components and maintaining structural integrity. It is often used in applications where components need to be securely fastened without the use of nuts, such as in engine blocks, transmission housings, and other high-stress areas. By providing a strong, vibration-resistant connection, the stud helps ensure the reliable operation of the truck’s mechanical systems 2.

Key Features

The 3954510 Double End Plain Stud boasts several key features that make it suitable for heavy-duty applications. It is typically made from high-strength alloy steel, ensuring durability and resistance to wear. The stud’s thread specifications are designed to meet industry standards, providing a secure fit and reliable performance. Additionally, its plain design, without any additional features like shoulders or collars, allows for versatile use in various applications.

Benefits of Using Double End Plain Studs

Double End Plain Studs offer several advantages in commercial truck applications. Their durability ensures long-term reliability, reducing the need for frequent replacements. The ease of installation, without the requirement for nuts, simplifies the assembly process and reduces the risk of errors. Furthermore, their reliability in high-stress environments makes them an ideal choice for critical connections in commercial trucks 3.

Installation Process

Proper installation of the 3954510 Double End Plain Stud is crucial for optimal performance and longevity. The installation process involves threading the stud into the designated holes in the components it connects. It is important to ensure that the stud is tightened to the manufacturer’s specified torque settings to achieve the correct tension and secure fit. Using the appropriate tools and following a systematic approach will help maintain the integrity of the connection and the overall performance of the truck.

Common Applications

The 3954510 Double End Plain Stud is commonly used in various systems within commercial trucks. Typical applications include securing engine blocks, transmission housings, and other critical components. Its versatility and strength make it a valuable component in ensuring the structural integrity and reliable operation of the truck’s mechanical systems.

Troubleshooting and Maintenance

Identifying and resolving common issues related to Double End Plain Studs can help maintain their service life and ensure optimal performance. Regular inspection for signs of wear, corrosion, or loosening is recommended. If any issues are detected, the stud should be replaced or tightened as necessary. Additionally, ensuring that all components are clean and free of debris before installation will help prevent future problems.

Safety Considerations

When working with Double End Plain Studs, it is important to observe several safety guidelines and precautions. Always use the appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that all tools and equipment are in good working condition before use. Follow the manufacturer’s torque specifications to avoid over-tightening, which can damage the stud or the components it connects. Additionally, be mindful of the surrounding environment to prevent accidents and ensure the safety of both the technician and the equipment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name in the industry.

Compatibility of Cummins Part 3954510 with Various Engine Models

The Cummins Double End Plain Stud, part number 3954510, is a critical component in several of Cummins’ engine models. This part is designed to provide robust and reliable fastening in various engine applications. Below is a detailed look at the compatibility of this part with the specified engine models:

15N CM2380 M104B

The 15N CM2380 M104B engine benefits from the Double End Plain Stud for its structural integrity, ensuring secure connections in critical areas.

4B3.9

In the 4B3.9 engine, the Double End Plain Stud is utilized for its durability and strength, providing a reliable fastening solution in demanding environments.

ISBE CM800, ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, ISF4.5 CM2220 F123

These engines, including ISBE CM800, ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, and ISF4.5 CM2220 F123, all incorporate the Double End Plain Stud for its precision and reliability in fastening applications.

ISG11 CM2880 G108, ISG12 CM2880 G107, ISG12 G CMOH6.0 G111

The ISG11 CM2880 G108, ISG12 CM2880 G107, and ISG12 G CMOH6.0 G111 engines utilize the Double End Plain Stud for its ability to withstand high stresses and provide a secure connection.

QSB4.5 CM850(CM2850), QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, QSF2.8 CM2880 F114

The QSB4.5 CM850(CM2850), QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F114 engines all feature the Double End Plain Stud for its precision and reliability in fastening applications.

X11 CM2670 X126B, X12 CM2670 X121B, X12N CMMDG1 X143B, X13 CM2670 X122B

The X11 CM2670 X126B, X12 CM2670 X121B, X12N CMMDG1 X143B, and X13 CM2670 X122B engines incorporate the Double End Plain Stud for its durability and strength, ensuring secure connections in critical areas.

This part is essential for maintaining the structural integrity and operational efficiency of these engines, providing a reliable fastening solution across various engine models.

Role of Part 3954510 Double End Plain Stud in Engine Systems

The Double End Plain Stud 3954510 is an essential component in various engine systems, facilitating secure and reliable connections across multiple assemblies.

Connection

In engine systems, the Double End Plain Stud serves as a robust connecting element. It is often used to link two or more components securely, ensuring that the assemblies remain firmly in place under operational stress. This is particularly important in high-vibration environments where standard bolts might loosen over time.

Exhaust Outlet

At the exhaust outlet, the Double End Plain Stud plays a significant role in maintaining the integrity of the exhaust system. It helps in securing the exhaust manifold to the engine block or other exhaust components, ensuring a tight seal that prevents exhaust leaks. This not only enhances performance but also reduces emissions and noise.

Fan Shroud Support

The fan shroud support is another area where the Double End Plain Stud is vital. It secures the fan shroud to the engine, ensuring that the shroud remains in the correct position. This is important for directing airflow efficiently over the engine cooling fan and other heat-generating components, thereby optimizing cooling performance.

Shroud

Within the shroud assembly, the Double End Plain Stud helps in maintaining the structural integrity of the shroud. It ensures that the shroud remains securely attached to the engine, which is essential for effective airflow management around the engine components.

Engine Cooling Fan

For the engine cooling fan, the Double End Plain Stud is used to attach the fan to its housing or the engine block. This secure attachment is vital for the fan’s operation, ensuring it can spin freely without wobbling, which could otherwise lead to inefficient cooling and potential damage to the fan or surrounding components.

Turbocharger

In turbocharger applications, the Double End Plain Stud is used to secure the turbocharger to the engine block or exhaust manifold. This ensures that the turbocharger remains firmly in place, even under the high stresses and temperatures it experiences. Proper attachment is essential for the turbocharger’s efficiency and longevity.

Overall, the Double End Plain Stud 3954510 is a versatile and reliable component that enhances the performance and durability of various engine systems by providing secure and stable connections.

Conclusion

The Double End Plain Stud 3954510 is a critical component in the automotive industry, particularly for commercial trucks and heavy-duty applications. Its robust design, ease of installation, and reliability make it an essential part for maintaining the structural integrity and operational efficiency of engine systems. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.