This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

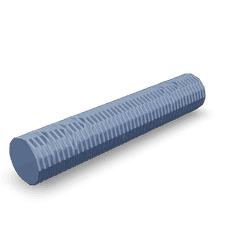

The Cummins 4014594 Stud is a specialized component designed for use in commercial truck operations. Its purpose is to provide secure fastening in various engine components, ensuring the integrity and reliability of the truck’s performance. The significance of this stud lies in its ability to withstand high stress and maintain a strong connection under demanding conditions, which is vital for the efficient operation of commercial vehicles 1.

Basic Concepts of Studs

A stud is a threaded fastener with external male threads on both ends, designed to be permanently fixed at one end into a tapped hole. It functions by providing a secure connection between two or more components, allowing for easy assembly and disassembly. In the automotive industry, studs are commonly used in engine components, chassis parts, and other critical areas where durability and strength are required 2.

Purpose of the 4014594 Stud

This Cummins part plays a specific role in the operation of a commercial truck by securing critical engine components. It is typically used in applications where high tensile strength and resistance to vibration are necessary. This stud ensures that engine parts remain firmly in place, contributing to the overall stability and performance of the truck.

Key Features

The 4014594 Stud is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, ensuring resistance to corrosion and wear. The stud features precise threading, which provides a secure fit and reduces the risk of loosening over time. Additionally, its design may include unique elements such as a hex head for easy installation and removal using standard tools.

Benefits

The advantages provided by the 4014594 Stud include improved reliability and enhanced performance of the truck’s engine. Its robust construction ensures that it can withstand the high stresses and vibrations encountered in commercial truck operations. Furthermore, the use of high-quality studs can lead to potential cost savings for fleet operators by reducing the need for frequent replacements and maintenance.

Installation and Usage

Proper installation of the 4014594 Stud is crucial for ensuring optimal performance. Guidelines for installation include using the correct torque specifications to achieve the right tension without over-tightening, which could damage the stud or the components it secures. Special considerations may include the use of thread lockers to prevent loosening and ensuring that all mating surfaces are clean and free of debris.

Troubleshooting and Maintenance

Common issues associated with studs include loosening, corrosion, and thread damage. Troubleshooting these problems involves inspecting the stud for signs of wear or damage, ensuring that it is properly torqued, and addressing any environmental factors that may contribute to corrosion. Maintenance tips to prolong the life of the 4014594 Stud include regular inspection, cleaning, and the application of protective coatings where necessary.

Safety Considerations

When handling and installing the 4014594 Stud, it is important to follow safety guidelines to prevent injury and ensure proper installation. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses. Safe work practices involve using the correct tools and following manufacturer recommendations for torque settings and installation procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, known for its commitment to quality and innovation. The company’s products are designed to meet the demanding requirements of commercial operations, providing reliable and efficient power solutions.

Stud Part 4014594 in Cummins Engines

The Stud part 4014594, manufactured by Cummins, is a critical component in several Cummins engine models. This part is integral to the assembly and operation of these engines, ensuring structural integrity and proper functioning.

QSV91G Engine

In the QSV91G engine, the Stud part 4014594 plays a pivotal role in maintaining the alignment and stability of various engine components. It is typically used in areas where high tensile strength and durability are required, such as in the engine block or cylinder head assembly. This ensures that the engine operates smoothly and efficiently, reducing the risk of mechanical failure.

Grouping of Engines

The Stud part 4014594 is also utilized in other Cummins engines, often grouped based on their application and performance requirements. For instance, in industrial and heavy-duty engines, this stud is essential for withstanding the rigorous conditions these engines face. The design and material of the stud are optimized to handle the stresses and strains associated with these demanding environments.

The use of the Stud part 4014594 across different Cummins engines highlights its versatility and importance in ensuring the reliability and longevity of the engine systems.

Role of Part 4014594 Stud in Engine Systems

Part 4014594, commonly referred to as a Studfit, is integral to the efficient operation of various engine components. One of its primary applications is within the Crankcase Breather Arrangement (CCBA).

In the CCBA, the Studfit plays a significant role in maintaining the system’s integrity and functionality. It ensures that the breather passages remain unobstructed, allowing for the effective venting of gases from the crankcase. This is essential for maintaining optimal engine performance and longevity.

The Studfit is also involved in securing components within the CCBA, such as the breather hoses and filters. By providing a stable mounting point, it helps to prevent leaks and ensure that the breather system operates within specified parameters. This contributes to the overall efficiency of the engine by facilitating the proper circulation of air and gases.

Furthermore, the Studfit aids in the structural support of the CCBA, helping to withstand the dynamic forces experienced during engine operation. This support is vital for the durability and reliability of the breather system, ensuring that it can perform its function under various operating conditions.

Conclusion

In summary, the 4014594 Stud is a key component in the Crankcase Breather Arrangement, contributing to the system’s efficiency, stability, and durability. Its role in securing and supporting critical elements within the CCBA underscores its importance in maintaining engine health and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.