This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

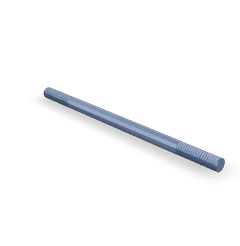

The Double End Plain Stud (Part #4016146) by Cummins is a specialized fastener designed for use in heavy-duty truck applications. This component is integral to the assembly and maintenance of various truck systems, ensuring secure connections and reliable performance under demanding conditions. Its role in the heavy-duty truck industry underscores the importance of durable and high-quality fasteners in ensuring the longevity and efficiency of truck operations 1.

Basic Concepts

A Double End Plain Stud is a type of fastener characterized by threaded sections on both ends, allowing it to be screwed into components from both sides. This design facilitates secure and stable connections in mechanical systems. In the context of heavy-duty trucks, these studs are used to join components that require strong, permanent fastening solutions. The structure of the stud typically includes a cylindrical body with uniform threading, designed to withstand high stress and vibration without loosening 2.

Purpose and Role

The Double End Plain Stud plays a significant role in the operation of heavy-duty trucks by providing a robust connection between various components. It is commonly used in applications such as engine mounts, transmission assemblies, and chassis components. By ensuring that critical parts remain securely fastened, the stud contributes to the overall stability and performance of the truck. Its applications extend to areas where vibrations and mechanical stress are prevalent, highlighting its importance in maintaining the integrity of truck systems 3.

Key Features

The Double End Plain Stud is distinguished by several key features that enhance its performance and durability. These include a high-quality material composition, typically made from alloy steel, which provides excellent strength and resistance to wear. The threading on both ends is precisely machined to ensure a secure fit and easy installation. Additionally, the design of the stud incorporates features that prevent loosening under vibration, such as a smooth, unthreaded section in the middle that allows for expansion and contraction without affecting the fastening integrity.

Benefits

The use of the Double End Plain Stud offers several benefits in heavy-duty truck applications. Its design contributes to improved mechanical stability by providing a strong and permanent connection between components. The ease of installation is another advantage, as the stud can be quickly and securely fastened using standard tools. Furthermore, the long-term reliability of the stud ensures that truck systems remain operational under demanding conditions, reducing the need for frequent maintenance and replacements.

Installation and Usage

Proper installation of the Double End Plain Stud is crucial for ensuring its effectiveness and longevity. The recommended procedure involves cleaning the mating surfaces to remove any debris or contaminants that could affect the fastening integrity. Using a torque wrench, the stud should be tightened to the manufacturer’s specified torque settings to achieve the optimal tension without overtightening. It is also advisable to apply a thread locker to the threads to prevent loosening due to vibrations.

Troubleshooting and Maintenance

Common issues associated with Double End Plain Studs include loosening due to vibrations and corrosion in harsh environments. Regular inspection and maintenance can help identify and address these issues before they lead to component failure. Troubleshooting tips include checking for proper torque settings and ensuring that mating surfaces are clean and free of corrosion. Maintenance practices such as applying anti-seize compound to the threads can prolong the service life of the stud by reducing friction and preventing galling.

Safety Considerations

When handling, installing, or maintaining the Double End Plain Stud, it is important to observe several safety guidelines to prevent accidents and ensure operational safety. These include wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect against injuries from sharp edges or flying debris. Additionally, ensuring that the work area is clean and free of obstructions can help prevent accidents during installation or maintenance procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for professionals in the field.

Double End Plain Stud (Part 4016146) Compatibility with Cummins Engines

The Double End Plain Stud, identified by the part number 4016146, is a critical component in the assembly of various Cummins engines. This part is designed to ensure secure and reliable connections within the engine, facilitating the proper functioning of engine components.

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines are part of Cummins’ QSK series, which are known for their robust design and high performance. The Double End Plain Stud is integral to these engines, providing a stable connection point that can withstand the stresses and vibrations inherent in engine operation. This part is typically used in areas where dual-ended connections are necessary, ensuring that the components remain securely fastened and aligned.

QSK78 CM500

The QSK78 CM500 engine, another member of the QSK series, also benefits from the use of the Double End Plain Stud. This engine, like its counterparts, relies on the precision and durability of the 4016146 part to maintain the integrity of its internal connections. The stud’s design allows for efficient assembly and disassembly, which is crucial during maintenance and repair operations.

Grouping the Engines

When considering the QSK45 CM500, QSK60 CM500, and QSK78 CM500 engines together, it is evident that the Double End Plain Stud plays a pivotal role in their operation. These engines, while differing in size and power output, share a common need for reliable and robust connection points. The 4016146 part meets this requirement by providing a sturdy and dependable solution that enhances the overall performance and longevity of the engines.

Part 4016146 Double End Plain Stud Component Usage

The part 4016146 Double End Plain Stud is integral to the assembly and operation of several key components within engine systems.

In the cover assembly, this stud serves as a pivotal connection point, ensuring the cover is securely fastened to the engine block. Its dual-ended design allows for a firm grip on both sides, enhancing the structural integrity of the cover and preventing any potential leaks or misalignments.

For the front gear, the Double End Plain Stud is used to anchor the gear in place, ensuring it remains aligned with the drive mechanism. This alignment is essential for the smooth transfer of power from the engine to the gear, reducing wear and tear and enhancing the overall efficiency of the engine system.

In the drive component, the stud plays a role in maintaining the stability of the drive mechanism. By securely fastening the drive to the engine block, it ensures that the drive operates within the correct parameters, contributing to the consistent performance of the engine.

Lastly, in the fan assembly, the Double End Plain Stud is utilized to attach the fan to the engine. This connection is vital for the proper functioning of the fan, as it ensures that the fan blades are correctly positioned and can operate efficiently to cool the engine, preventing overheating and maintaining optimal engine temperature.

Conclusion

The Double End Plain Stud (Part #4016146) by Cummins is a critical component in the heavy-duty truck industry, providing secure and reliable connections in various engine systems. Its robust design, ease of installation, and long-term reliability make it an essential part for maintaining the performance and longevity of heavy-duty trucks. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.