4325573

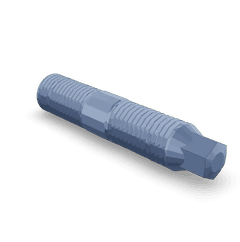

Double End Collar Stud

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 4325573 Double End Collar Stud, a component manufactured by Cummins, is designed for use in commercial trucks. This article provides an overview of this Cummins part, its function, key features, benefits, and maintenance suggestions.

Basic Concepts and Functionality

A Double End Collar Stud is a type of fastener used in various mechanical applications. It features two threaded ends separated by a collar, allowing it to secure multiple components together. In the context of commercial trucks, it plays a role in assembling and securing parts within the engine and other critical systems 1.

Purpose and Role in Truck Operation

The 4325573 Double End Collar Stud is utilized in commercial trucks to ensure the secure attachment of components. It is commonly found in engine assemblies, where it helps maintain the integrity of the engine’s structure by connecting various parts. Its design allows for efficient distribution of load and stress across the connected components 2.

Key Features

- Dual-threaded design for secure fastening

- Robust construction to withstand high stress and vibration

- Precision-machined to ensure accurate fit and function

- Made from high-quality materials to enhance durability and reliability

Benefits

- Enhanced security of component attachment

- Improved load distribution across connected parts

- Increased durability and resistance to wear and tear

- Reliable performance in high-stress environments typical of commercial truck operations

Troubleshooting and Maintenance

Regular inspection of the Double End Collar Stud is recommended to ensure it remains in good condition. Signs of wear, corrosion, or damage should be addressed promptly to prevent failure. Maintenance practices include:

- Checking for proper torque during installation

- Inspecting for signs of wear or damage during routine maintenance

- Replacing the stud if any defects are detected to maintain the integrity of the assembly

Compatibility with Cummins Engines

The Double End Collar Stud, part number 4325573, is designed to fit seamlessly within various engine configurations. This part is integral to maintaining the structural integrity of engines like the ISV (Nissan) engines. Its dual-ended design allows it to secure components from both sides, providing a robust connection that can withstand the stresses of engine operation 3.

Role in Engine Systems

Air Intake Manifold

In the air intake manifold, the Double End Collar Stud serves as a pivotal connection point. It secures the manifold to the engine block, ensuring a tight seal that prevents air leaks. This seal is essential for maintaining the correct air-fuel ratio, which is vital for optimal engine performance and efficiency.

Turbocharger Arrangement

Within the turbocharger arrangement, the Double End Collar Stud plays a significant role in connecting the turbocharger to the exhaust manifold. This connection must withstand high temperatures and pressures, making the robust design of the stud particularly suitable. The stud ensures that the turbocharger is firmly attached, allowing it to operate efficiently without the risk of detachment or misalignment.

Conclusion

The 4325573 Double End Collar Stud is a critical component in the assembly and functionality of various engine components in commercial trucks. Its design and construction ensure secure connections, efficient operation, and reliable performance in high-stress environments. Regular maintenance and inspection are essential to ensure the longevity and efficiency of the engine systems in which it is used.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.