This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The High Temperature Stud (Part #4327413) by Cummins is a specialized component designed to withstand extreme thermal conditions encountered in heavy-duty truck operations. Its purpose is to secure various engine components under high-temperature environments, ensuring reliable performance and longevity of the truck’s engine system. This stud is significant in maintaining the integrity and efficiency of heavy-duty truck engines, which are often subjected to rigorous operating conditions 1.

Basic Concepts of High Temperature Studs

High temperature studs are fasteners engineered to operate in environments where conventional fasteners would fail due to heat. They are commonly used in automotive and industrial applications where components are exposed to high temperatures, such as in engine blocks, exhaust manifolds, and turbochargers. These studs are designed to maintain structural integrity and resist thermal expansion, corrosion, and creep, ensuring secure fastening under extreme conditions 2.

Purpose of the 4327413 High Temperature Stud in Truck Operations

This part plays a specific role in the operation of heavy-duty trucks by securing critical engine components that are exposed to high temperatures. It is typically used in areas such as cylinder heads, exhaust manifolds, and turbocharger housings. The stud’s ability to withstand thermal stress ensures that these components remain firmly in place, contributing to the overall reliability and performance of the truck’s engine 3.

Key Features of the 4327413 High Temperature Stud

The 4327413 High Temperature Stud is distinguished by several key features that enhance its performance. It is made from a high-strength alloy that provides excellent resistance to heat and corrosion. The stud is designed with precise threading and a robust construction to ensure a secure fit. Additionally, it may feature a special coating or treatment to further improve its durability and resistance to thermal cycling.

Benefits of Using the 4327413 High Temperature Stud

Incorporating this Cummins part into truck maintenance and repair offers several advantages. Its high-strength material composition ensures durability and reliability under extreme conditions. The stud’s design helps to maintain consistent performance, reducing the likelihood of fastener failure. This results in enhanced engine efficiency and longevity, contributing to the overall reliability of heavy-duty truck operations.

Installation Considerations

Proper installation of the 4327413 High Temperature Stud is crucial to ensure its effectiveness. It is recommended to use the appropriate tools and follow manufacturer guidelines to achieve the correct torque specifications. Safety precautions, such as wearing protective gear and ensuring the engine is cool before installation, should be observed. Careful attention to these details will help to prevent installation-related issues and ensure the stud functions as intended.

Troubleshooting Common Issues

Typical problems that may arise with high temperature studs include loosening due to thermal expansion, corrosion, or mechanical stress. To address these issues, regular inspections should be conducted to check for signs of wear or damage. If a stud is found to be loose, it should be re-torqued to the manufacturer’s specifications. In cases of severe corrosion or damage, replacement of the stud may be necessary to maintain engine integrity.

Maintenance Tips

Regular maintenance of the 4327413 High Temperature Stud is important to prolong its lifespan and ensure consistent performance. Inspection routines should include checking for signs of corrosion, wear, or loosening. Cleaning the stud and its surrounding area can help prevent the buildup of contaminants that may accelerate wear. Following these maintenance practices will help to maintain the stud’s effectiveness and contribute to the overall reliability of the truck’s engine system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and industrial sectors. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of various applications, including heavy-duty trucks.

Compatibility of High Temperature Stud (Part 4327413) with Cummins Engines

This part, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. It is engineered to withstand extreme temperatures, making it an ideal choice for applications where durability and performance are critical.

Engines Compatible with Part 4327413

15N CM2380 M104B

This engine benefits from the high-temperature resistance of the stud, ensuring reliable performance in demanding conditions.

ISZ13 CM2150 Z105, QSZ13 CM2150 Z101, QSZ13 CM2150 Z102

These engines, part of the CM2150 series, are well-suited for the use of the High Temperature Stud. The part’s design allows for precise fitting and secure fastening, which is crucial for maintaining engine integrity under high-stress operations.

Z13 Z108G

The Z13 Z108G engine also integrates the High Temperature Stud effectively. Its robust construction ensures that the stud can handle the thermal and mechanical stresses encountered during operation.

Z14 CM2670 Z103B

Lastly, the Z14 CM2670 Z103B engine is another beneficiary of this high-performance stud. Its compatibility with the part ensures that the engine can operate efficiently and reliably, even in the most challenging environments.

By using the High Temperature Stud (Part 4327413) in these Cummins engines, users can expect enhanced durability and performance, making it a valuable component for maintaining engine functionality.

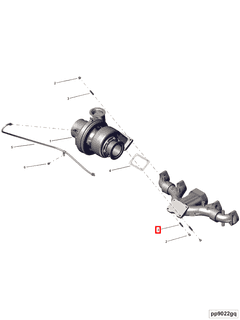

Role of Part 4327413 High Temperature Stud in Turbocharger Systems

In turbocharger systems, this part is instrumental in maintaining the structural integrity and operational efficiency of the turbocharger assembly. It is specifically designed to withstand the extreme temperatures and pressures encountered within the turbocharger environment.

Turbocharger Housing Assembly

Within the turbocharger housing assembly, the High Temperature Stud secures the turbine and compressor wheels to the housing. This ensures that the wheels remain firmly in place despite the high rotational speeds and thermal stresses. The stud’s robust construction helps prevent any shifting or misalignment that could lead to performance issues or mechanical failure.

Turbine and Compressor Wheel Connection

The connection between the turbine and compressor wheels is another area where the High Temperature Stud plays a significant role. By providing a reliable fastening mechanism, it ensures that the wheels operate in unison, optimizing the airflow and pressure dynamics essential for efficient turbocharging. This connection is vital for maintaining the balance and synchronization of the turbocharger’s rotating components.

Exhaust and Intake Manifold Integration

When integrating the turbocharger with the exhaust and intake manifolds, the High Temperature Stud contributes to a secure and leak-free seal. This is important for maximizing the efficiency of the exhaust gas recirculation and ensuring that the intake air is properly pressurized. The stud’s high-temperature resistance helps maintain the integrity of these seals under varying operating conditions.

Heat Shield and Insulation Systems

In heat shield and insulation systems, the High Temperature Stud is used to attach heat-resistant materials to the turbocharger housing. This attachment is essential for protecting surrounding engine components from the intense heat generated by the turbocharger. The stud’s ability to withstand thermal expansion and contraction ensures that the heat shields remain effectively positioned.

Lubrication and Cooling Systems

In lubrication and cooling systems associated with the turbocharger, the High Temperature Stud helps secure oil feed lines and cooling passages. This ensures that the turbocharger receives consistent lubrication and cooling, which is essential for prolonging its operational life and enhancing performance. The stud’s reliable fastening capability is key to maintaining the integrity of these critical systems.

Performance Monitoring and Maintenance

During performance monitoring and maintenance procedures, the High Temperature Stud facilitates easy access to turbocharger components. Its design allows for straightforward removal and reinstallation, which is important for routine inspections and repairs. The stud’s durability ensures that it can withstand multiple disassembly and reassembly cycles without degradation.

Conclusion

The 4327413 High Temperature Stud by Cummins is a critical component in the maintenance and operation of heavy-duty truck engines and turbocharger systems. Its high-strength alloy construction, precise threading, and robust design ensure reliable performance under extreme thermal conditions. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this part, contributing to the overall efficiency and longevity of the engine system.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

John Heywood, Internal Combustion Engine Fundamentals, McGraw-Hill Education, 2019.

↩ -

Alan Robinson and Andrew Livesey, The Repair of Vehicle Bodies Fifth Edition, Elsevier, 2006.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.