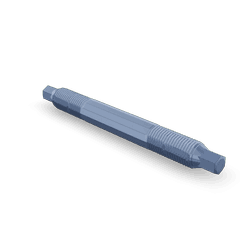

4359833

High Temperature Stud

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The High Temperature Stud (Part #4359833) by Cummins is a specialized component designed for use in heavy-duty truck applications. This stud is engineered to withstand extreme temperatures and pressures, ensuring reliable performance in demanding environments. Its role is significant in maintaining the integrity and efficiency of truck engines, particularly in high-stress areas such as the exhaust system.

Basic Concepts of High Temperature Studs

High temperature studs are fasteners designed to operate in environments where conventional studs would fail due to heat and stress. They are commonly used in engines and machinery where components are exposed to high temperatures, such as exhaust manifolds, turbochargers, and other high-heat areas. These studs are crafted from materials that can endure thermal expansion, corrosion, and mechanical stress, ensuring they remain secure and functional under extreme conditions 1.

Purpose and Role in Truck Operation

This Cummins part plays a specific role in the operation of a truck by securing components within the engine or exhaust system that are subject to high temperatures. It ensures that parts remain firmly in place, preventing leaks and maintaining the structural integrity of the system. This stud is particularly important in areas where thermal cycling occurs, as it must withstand repeated heating and cooling without losing its tensile strength or becoming brittle.

Key Features

The 4359833 High Temperature Stud is characterized by several key features that enhance its performance. It is made from a high-nickel alloy, which provides excellent resistance to heat and corrosion. The stud’s design includes a threaded section for secure fastening and a shank that is optimized for strength and durability. Additionally, it may feature a special coating or treatment to further improve its resistance to oxidation and wear.

Benefits

Using this part offers several benefits. Its material composition and design contribute to improved durability, allowing it to withstand the harsh conditions of heavy-duty truck engines. The stud’s resistance to high temperatures ensures that it maintains its structural integrity and performance over time. Furthermore, its enhanced features contribute to the overall reliability and efficiency of the truck’s engine system.

Installation Considerations

Proper installation of the 4359833 High Temperature Stud is vital to ensure optimal performance and longevity. It is important to follow torque specifications provided by the manufacturer to avoid over-tightening, which can lead to stud failure, or under-tightening, which can result in loose connections. Recommended procedures include using the correct tools and techniques to install the stud, such as applying a thread lubricant to prevent seizing and ensuring that mating surfaces are clean and free of debris.

Troubleshooting and Maintenance

Common issues with high temperature studs, such as corrosion, loosening, or failure, can often be traced back to improper installation or environmental factors. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Maintenance tips include checking for signs of wear or damage, ensuring that studs are properly torqued, and replacing studs that show signs of corrosion or fatigue.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related components. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance parts. The 4359833 High Temperature Stud is a testament to Cummins’ dedication to providing durable and efficient components for the automotive industry.

Compatibility with Cummins Engines

This part is compatible with various Cummins engine configurations, providing robust support and durability. It is engineered to fit seamlessly within different engine families, ensuring a secure and reliable connection. This compatibility is crucial for maintaining engine efficiency and longevity, especially in high-temperature environments where other materials might fail.

ISV (Nissan) Engines

The High Temperature Stud is compatible with the ISV (Intelligent Systems Vehicle) engines produced by Nissan. These engines are known for their efficiency and reliability, often used in heavy-duty applications. The stud’s design ensures it can endure the high temperatures and pressures typical in these engines, maintaining structural integrity and performance over time.

Cummins Engine Families

The High Temperature Stud is also compatible with several Cummins engine families, including but not limited to:

-

Cummins B Series Engines: These engines are widely used in agricultural and construction equipment. The stud’s ability to withstand high temperatures makes it ideal for these applications, where engines often operate under strenuous conditions.

-

Cummins C Series Engines: Known for their versatility and power, these engines are used in a variety of applications, from marine to industrial. The High Temperature Stud’s durability ensures it can handle the rigors of these demanding environments.

-

Cummins Q Series Engines: These engines are designed for heavy-duty applications, such as mining and construction. The stud’s robust construction is perfectly suited to the high-stress conditions these engines encounter.

Industrial and Marine Applications

In industrial and marine settings, the High Temperature Stud is a vital component for maintaining engine reliability. Its compatibility with various engine types ensures that it can be used across different platforms, providing a consistent level of performance and durability.

Role of Part 4359833 High Temperature Stud in Engine Systems

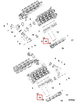

Air Intake Manifold

The air intake manifold is a vital component in any engine system, responsible for distributing air evenly to each cylinder. This part plays a significant role in securing the manifold to the engine block. This ensures a tight seal, preventing air leaks that could otherwise compromise engine performance. The stud’s high-temperature resistance is essential for withstanding the thermal stresses generated during engine operation, maintaining structural integrity and reliability over time.

Long Block Kit

A long block kit typically includes the engine block, crankshaft, pistons, and other essential components, excluding the intake and exhaust manifolds, fuel system, and ancillary components. This Cummins part is often utilized in the assembly of these kits to secure various components that are exposed to high temperatures. Its application ensures that all parts remain firmly in place, even under the extreme conditions encountered during engine operation. This contributes to the overall durability and performance of the long block kit.

Turbocharger Arrangement

In turbocharged engine systems, the turbocharger arrangement is designed to increase the engine’s power output by forcing extra air into the combustion chamber. This part is employed in securing components within the turbocharger arrangement, such as the turbocharger housing to the engine block or exhaust manifold. Its high-temperature capabilities are vital for withstanding the intense heat generated by the turbocharger, ensuring a secure and leak-free connection. This not only enhances the efficiency of the turbocharger but also contributes to the engine’s overall reliability and performance.

Conclusion

The 4359833 High Temperature Stud by Cummins is a critical component in heavy-duty truck engines, designed to withstand extreme temperatures and pressures. Its compatibility with various Cummins engine families and its role in securing critical engine components ensure reliable performance and durability. Proper installation and maintenance are essential to maximize the benefits of this part, contributing to the overall efficiency and longevity of the engine system.

-

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.