This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4900868 Stud, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the commercial truck industry, produces a range of parts and engines known for their reliability and performance. This Cummins part is significant in maintaining the integrity and efficiency of various engine components in commercial trucks.

Basic Concepts of Studs

A stud is a threaded fastener with external male threads on both ends. It functions by being inserted through holes in assembled parts and secured with a nut at each end. In the automotive industry, studs are commonly used in applications requiring frequent disassembly and reassembly, or where high tensile strength is needed 1.

Purpose of the 4900868 Stud

This part plays a role in the operation of commercial trucks by securing various engine components. It is utilized in areas where consistent clamping force and resistance to vibration are required. This stud ensures that parts remain firmly in place under the dynamic conditions experienced by commercial trucks.

Key Features

The 4900868 Stud is characterized by specific design and material attributes. It features a particular thread size and length, tailored to fit its intended applications. The material composition is chosen for its strength and durability, often including alloys that provide resistance to wear and corrosion. Additionally, the stud may have special coatings or treatments to enhance its performance in demanding environments 2.

Benefits

The advantages of the 4900868 Stud include enhanced durability, which is crucial for the longevity of engine components in commercial trucks. Its resistance to corrosion ensures reliable performance even in harsh operating conditions. Furthermore, the stud’s design contributes to improved performance under high-stress environments, maintaining the integrity of the assembly it is part of 3.

Installation Process

Proper installation of the 4900868 Stud involves several steps to ensure it functions correctly. The process includes aligning the stud with the designated holes in the engine components, threading it through, and securing it with nuts on each end. Torque specifications are critical to apply the correct amount of force without over-tightening, which could damage the stud or the components it secures. Precautions such as using the correct tools and ensuring the area is clean and free of debris are necessary to prevent installation issues.

Troubleshooting and Maintenance

Common issues with studs in commercial trucks include loosening over time due to vibration or corrosion. Identifying problems early can prevent more significant issues. Maintenance practices for the 4900868 Stud involve regular inspection for signs of wear or corrosion, ensuring nuts are properly torqued, and replacing the stud if it shows signs of damage or excessive wear.

Compatibility and Applications

The 4900868 Stud is designed for use in specific commercial truck models and engine types. Its application is tailored to fit within the engineering specifications of these vehicles, ensuring compatibility and optimal performance. Understanding the compatibility of this stud with various truck models is important for its effective use.

Safety Considerations

When handling, installing, or maintaining the 4900868 Stud, adhering to safety guidelines is important. This includes using personal protective equipment, following proper lifting techniques for heavy components, and ensuring the work area is safe and free from hazards. Compliance with industry standards for torque specifications and maintenance practices helps prevent accidents and ensures the reliability of the installation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Compatibility with A1700, A2000, and A2300 Engines

The Cummins Stud part number 4900868 is designed to be a critical component in the assembly of several engine models. This particular stud is engineered to meet the stringent requirements of the A1700, A2000, and A2300 engines, ensuring robust performance and reliability.

In the A1700 and A2000 engines, the stud is often utilized in areas where high tensile strength and durability are paramount. Its design allows it to withstand the stresses of engine operation, maintaining structural integrity over extended periods. The A2300 engine, being a more powerful variant, also benefits from the use of this stud, particularly in high-load applications where the demands on engine components are greater.

The compatibility of the stud across these engines is facilitated by its standardized dimensions and material properties. This standardization ensures that the stud can be seamlessly integrated into the engine’s design, providing a secure and reliable connection point. The precision in manufacturing guarantees that the stud fits perfectly, reducing the risk of misalignment or failure during operation.

Moreover, the use of this stud in these engines underscores Cummins’ commitment to quality and consistency. By employing a single part across multiple engine models, Cummins ensures that maintenance and repair processes are simplified, as technicians can use the same part for different engines, streamlining inventory management and reducing downtime.

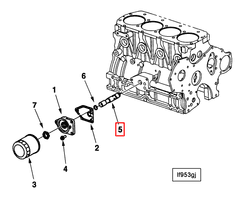

Role of 4900868 in Engine Systems

The 4900868 plays a significant role in maintaining the integrity and functionality of various engine components. In the context of the filter system, this stud is instrumental in securing the filter housing to the engine block or other mounting surfaces. It ensures a tight and stable connection, which is essential for the filter to perform its role effectively in trapping contaminants and maintaining the cleanliness of the engine oil.

In the lubricating oil system, the 4900868 is utilized to fasten components such as oil galleries, oil pumps, and oil filters. Its role here is to provide a secure attachment point that withstands the pressures and vibrations inherent in the operation of the engine. This secure fastening is vital for the consistent flow of lubricating oil throughout the engine, ensuring that all moving parts receive adequate lubrication to reduce friction, wear, and heat generation.

Moreover, the 4900868 is also involved in the assembly of oil coolers and oil pressure sensors. In these applications, it ensures that these components are firmly attached, allowing for accurate oil temperature regulation and precise monitoring of oil pressure within the engine. This contributes to the overall efficiency and reliability of the engine’s lubrication system.

In summary, the 4900868 is a key component in the assembly and operation of both the filter and lubricating oil systems within an engine. Its reliable performance is essential for the maintenance of clean engine oil and the efficient lubrication of engine components, directly influencing the engine’s longevity and operational efficiency.

Conclusion

The 4900868 Stud by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design, material properties, and compatibility with various engine models ensure reliable performance and durability. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part in commercial truck applications.

-

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Ribbens, W.B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.