This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

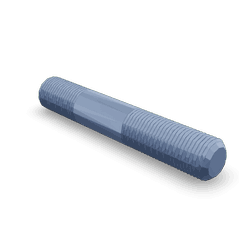

The Cummins 5295044 Double Ended Plain Stud is a specialized fastener designed for heavy-duty truck applications. Its purpose is to provide secure and reliable connections in various truck components, ensuring the integrity and performance of the vehicle. This stud is particularly significant in environments where durability and strength are paramount, such as in heavy-duty trucking.

Basic Concepts of Double Ended Plain Studs

A Double Ended Plain Stud is a type of fastener that features threads on both ends, allowing it to be used in applications where a traditional bolt and nut combination may not be feasible. The structure of a double-ended stud typically includes a cylindrical body with uniform threading along its length. In mechanical systems, these studs play a role in creating strong, permanent connections between components, often used in high-stress areas where vibration and movement are common 1.

Role of the 5295044 Double Ended Plain Stud in Truck Operation

The 5295044 Double Ended Plain Stud plays a specific role in the operation and maintenance of heavy-duty trucks by providing a robust fastening solution in critical areas. It is often used in engine components, transmission systems, and other high-stress applications where secure and lasting connections are required. The stud helps maintain the structural integrity of these components, ensuring that they function correctly under demanding conditions.

Key Features

The 5295044 Double Ended Plain Stud is characterized by several key features that enhance its performance and reliability. It is typically made from high-strength materials, such as alloy steel, which provide excellent durability and resistance to wear. The threading on the stud is precise and uniform, ensuring a secure fit in the corresponding tapped holes. Additionally, the design of the stud allows for easy installation and removal, facilitating maintenance procedures.

Benefits of Using the 5295044 Double Ended Plain Stud

Incorporating the 5295044 Double Ended Plain Stud in truck assemblies offers several advantages. Its high-strength material composition ensures durability, making it suitable for heavy-duty applications. The reliable threading and design characteristics contribute to the overall performance and longevity of the truck components it is used in. Additionally, the stud’s ability to provide a permanent fastening solution reduces the need for frequent maintenance, enhancing the efficiency of truck operations 2.

Installation Procedures

Proper installation of the 5295044 Double Ended Plain Stud is vital to ensure optimal performance and longevity. The installation process involves several steps: First, the corresponding holes in the components must be clean and free of debris. The stud should then be carefully threaded into the tapped hole, ensuring it is aligned correctly. It is important to use the appropriate torque specifications to secure the stud without over-tightening, which could damage the threads or the component itself. Finally, any necessary lock washers or other fasteners should be installed to prevent the stud from loosening over time.

Maintenance and Troubleshooting

Maintaining the 5295044 Double Ended Plain Stud involves regular inspections to ensure it remains secure and free of damage. Common issues to look for include signs of wear on the threads, corrosion, or loosening of the stud. If any of these issues are detected, the stud should be replaced or tightened as necessary. Troubleshooting may also involve checking for proper alignment and ensuring that all components are correctly installed. Regular maintenance helps prevent more significant problems down the line, ensuring the continued reliability of the truck 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing high-quality, reliable components. The company’s product range includes a variety of engines, powertrain components, and aftermarket parts, all designed to meet the demanding needs of heavy-duty applications. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name in the industry.

Cummins Double Ended Plain Stud 5295044 Compatibility

The Cummins Double Ended Plain Stud part number 5295044 is designed to fit seamlessly within the engine configurations of the B4.5 CM2350 B129B and ISB4.5 CM2350 B104 engines. This part is integral to the structural integrity and functionality of these engines, ensuring that various components are securely fastened and aligned.

In the B4.5 CM2350 B129B engine, the Double Ended Plain Stud 5295044 is utilized in critical areas where dual-ended fastening is required. Its robust design and precise engineering make it an essential component for maintaining the alignment and stability of engine parts, contributing to the overall performance and longevity of the engine.

Similarly, in the ISB4.5 CM2350 B104 engine, the Double Ended Plain Stud 5295044 plays a pivotal role in securing and aligning key engine components. The precision and durability of this part ensure that the engine operates smoothly and efficiently, with minimal wear and tear over time.

Both engines benefit from the use of this stud, as it provides a reliable method for fastening components, ensuring that the engine maintains its structural integrity and operational efficiency. The compatibility of the Double Ended Plain Stud 5295044 with these engines underscores its importance in the overall design and functionality of the B4.5 CM2350 B129B and ISB4.5 CM2350 B104 engines.

Part 5295044 Double Ended Plain Stud Component Usage

The part 5295044 Double Ended Plain Stud is a versatile component utilized in various engine systems, particularly in the assembly and maintenance of turbochargers. In turbocharger applications, this stud plays a significant role in securing and aligning components, ensuring the turbocharger operates efficiently and reliably.

In the turbocharger, the Double Ended Plain Stud is often used to mount the compressor wheel to the shaft. This secure attachment is essential for maintaining the balance and integrity of the turbocharger as it spins at high speeds. The stud’s design allows for precise alignment, which is vital for the smooth operation of the turbocharger.

Additionally, the Double Ended Plain Stud is employed in the attachment of the turbine housing to the engine block or exhaust manifold. This connection must be robust to withstand the high temperatures and pressures generated during operation. The stud ensures a tight and secure fit, preventing leaks and maintaining the efficiency of the turbocharger.

Furthermore, in some turbocharger designs, the Double Ended Plain Stud is used to connect the wastegate actuator to the turbocharger housing. This connection is important for the proper functioning of the wastegate, which regulates the turbocharger’s boost pressure. A secure and stable connection ensures that the wastegate can respond accurately to changes in engine load and RPM, contributing to the overall performance and safety of the engine system.

Conclusion

The Cummins 5295044 Double Ended Plain Stud is a critical component in heavy-duty truck applications, providing secure and reliable connections in various engine systems. Its high-strength material, precise threading, and robust design ensure durability and performance under demanding conditions. Proper installation and regular maintenance are essential to maximize the benefits of this stud, contributing to the overall efficiency and reliability of heavy-duty trucks.

-

Dictionary of Mechanical Engineering, D. K. Singh, Springer Nature, 2024

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.